New Buck Corporation CDVB200 User Manual

Page 10

Continued

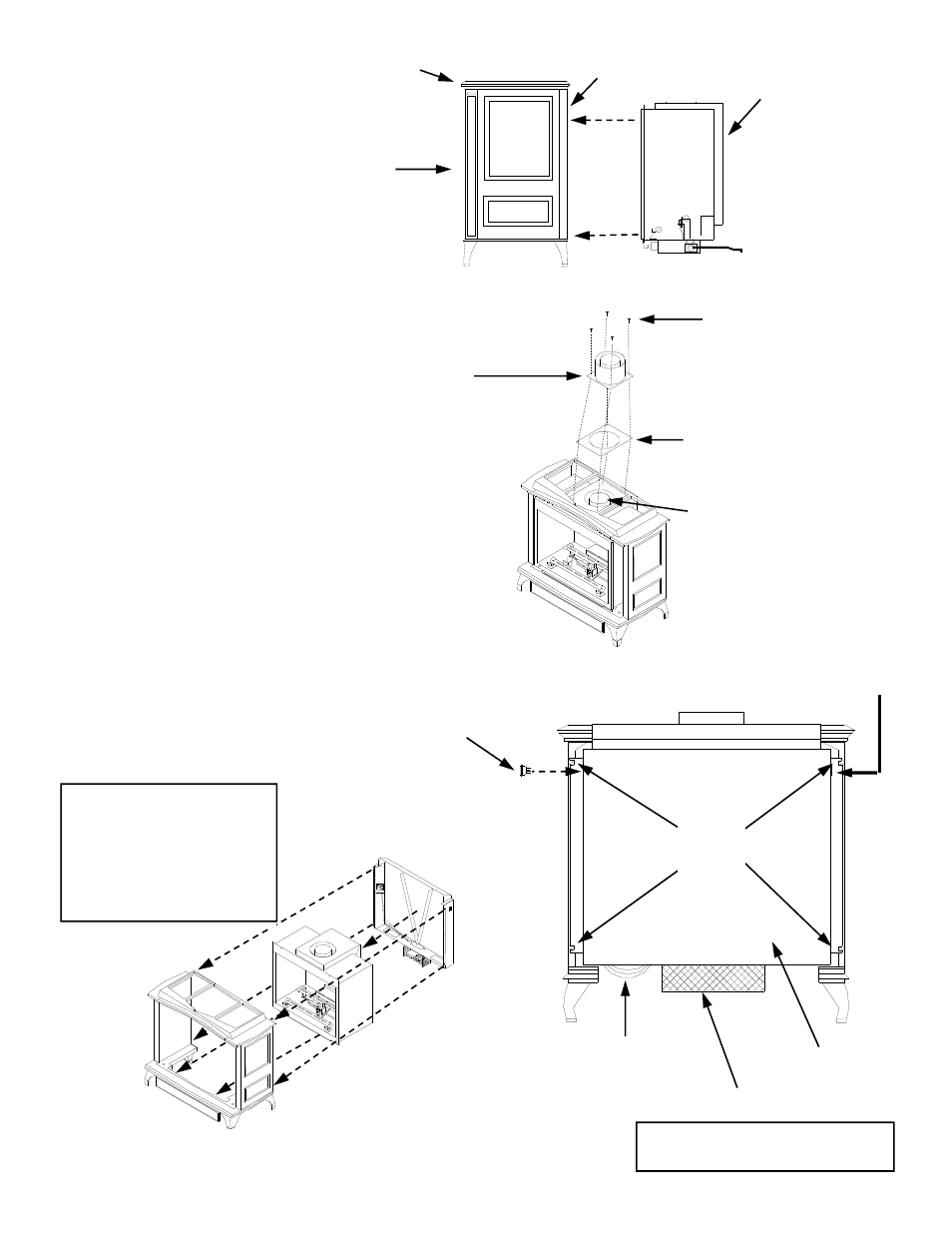

INSTALLING DIRECT-VENT

BURNER SYSTEM INTO STOVE

BODY

1. Carefully remove the burner system

(fire box) from the shipping box.

2. Carefully lift the burner system and

place it into the stove body from the

rear of the stove (see figure 13).

3. Slide the burner system to the front of

the stove body (see figures 13 and 14).

4. Place the vent gasket on the outside of

the burner system box over the vent

hole and align the holes(see figure 15).

5. Place the 7" vent collar over the gasket

and align the holes. Secure with hex

head screws provided (see figure 15).

6. Next remove the blower system from

the shipping box .

7. Find the on/off/auto switch and wires

attached to the burner system. You

will need to unplug the wires from the

switch and place the switch in the slot

provided on the side of the blower

system (see figure 16 and figures

43,44 on pages 30,31) .

8. Next push the wires through the 5/8"

round hole located in the bottom of the

blower system and reconnect the wires

to the switch using the labels on the

wires to insure the wires are

reconnected to the correct terminals

(see wiring diagram pages 30,31

figures 43,44)(see figure 16).

9. Secure the blower system to the rear

of the cast stove body with the 4

10mm bolts provided with the stove

(see figure 16).

Front

Stove Body

Burner System (Direct

Vent Fire Box)

Rear

Figure 13-Installing Burner System into Cast Stove body.

Figure 14– Installing Burner System and Blower System.

4 Hex Head Screws

7" Vent Collar

Vent Collar Gasket

Burner System Vent Opening

Figure 15– Installing Vent Collar

On/Off/Auto

Switch

Blower System

Labeled Wires from Burner System

Go to On/Off/Auto Switch

On/Off Switch

For Blower

Blower Motor

4 10mm

Bolts

Figure 16-Secure Blower System

WARNING: Never touch the blower

wheel while in operation.

“CAUTION:

Label all wires

prior to disconnection when

servicing controls. Wiring er-

rors can cause improper and

dangerous operation.”

“Verify proper operation after

servicing.”

6