Bryant 581A User Manual

Page 20

OPERATING SEQUENCE

COOLING, UNITS WITHOUT ECONOMIZER — When thermo-

stat calls for cooling, terminals G and Y1 are energized. The in-

door (evaporator) fan contactor (IFC) and compressor contactor

no. 1 (C1) are energized, and evaporator-fan motor, compres-

sor no. 1 (581A180,240) or unloaded compressor (581A155),

and condenser fan start. The condenser-fan motor runs continu-

ously while unit is cooling. For units with 2 stages of cooling, if

the thermostat calls for a second stage of cooling by energizing

Y2, compressor contactor no. 2 (C2) is energized and compres-

sor no. 2 starts (581A180,240) or compressor no. 1 runs fully

loaded (581A155).

HEATING, UNITS WITHOUT ECONOMIZER

NOTE: The 581A155 (High Heat), 180,240 units have 2 stages

of heat.

Set thermostat system switch at HEAT or AUTO. position and

set fan switch to AUTO. position for heating.

When first-stage thermostat calls for heat, time-delay relay for

evaporator fan begins timer sequence. Induced-draft relay

closes, and induced-draft motor starts.

Pressure switch closes and pilot valve no. 1 opens, allowing gas

to flow to the first-stage pilot. Spark ignitor ignites pilot flame.

Sensor detects flame and the main gas valve no. 1 opens. Gas

flows to main burners and first-stage burners ignite. Spark igni-

tor turns off.

When sequence is complete, time-delay relay closes and

evaporator fans start.

Second Stage — 581A155 High-Heat and 581A180,240

Units — With an additional heating call, the second-stage ther-

mostat closes. (The control relay closes during the first stage of

operation.) Pilot valve no. 2 opens, and the spark ignitor ignites

pilot. The sensor detects a flame and energizes main gas valve

coil no. 2, opening main gas valve no. 2. Gas flows to the main

burners, and the second stage burners ignite. The spark ignitor

turns off.

When the second-stage thermostat is satisfied, the second-

stage gas valve closes.

When the first-stage thermostat is satisfied, the first-stage gas

valve closes. The induced-draft motor turns off, the time relay

opens, and the timer sequence begins. When the sequence is

complete, the evaporator-fan motor turns off.

COOLING, UNITS WITH ECONOMIZER — Upon a call for

cooling, when outdoor ambient is above the enthalpy control

setting, the economizer damper moves to VENT position. The

compressor(s) and evaporator and condenser fans energize.

Upon a first call for cooling, when outdoor ambient is below the

enthalpy control setting, the evaporator fan starts and the

economizer is fully open. The compressor(s) remains off.

Upon a second-stage call for cooling, compressor no. 1 is en-

ergized and mechanical cooling is integrated with economizer

cooling. If the outdoor-air temperature drops below 50 F, a cool-

ing lockout switch prevents the compressors from running.

When supply-air temperature drops below a fixed set point, the

economizer damper modulates to maintain the temperature at

the fixed set point.

A freeze protection thermostat (FPT) is located on the evapora-

tor coil. It detects frost build-up and turns off the compressors,

allowing the coil to clear. Once frost has melted, the compres-

sors can be reenergized.

HEATING, UNITS WITH ECONOMIZER — Outdoor-air damper

stays at VENT position while evaporator fan is operating. Refer

to Heating, Units Without Economizer section above for remain-

der of operating sequence.

LEGEND FOR TYPICAL WIRING SCHEMATIC

BRK W/AT — Breaks with Amp Turns

C

— Contactor, Compressor

CLO

— Compressor Lockout

COM

— Common

CR

— Control Relay

CT

— Current Transformer

DM

— Damper Motor

FPT

— Freeze Protection Thermostat

GND

— Ground

HPS

— High-Pressure Switch

HR

— Heat Relay

HV

— High Voltage

IP

— Ignitor Pilot

ICP

— Ignitor Control Pack

IDR

— Induced Draft Relay

IFR

— Indoor (Evaporator) Fan Relay

LOR

— Lockout Relay

LPS

— Low-Pressure Switch/Loss of Charge

LS

— Limit Switch

MAT

— Mixed Air Thermostat

MGV

— Main Gas Valve

MV

— Main Valve

OAT

— Outdoor-Air Thermostat

OFC

— Outdoor (Condenser) Fan Contactor

PGV

— Pilot Gas Valve

PL

— Plug Assembly

PRI

— Primary

PV

— Pilot Valve

SN

— Sensor

TB

— Terminal Block

TDR

— Time-Delay Relay

TR

— Timer Relay

TRAN — Transformer

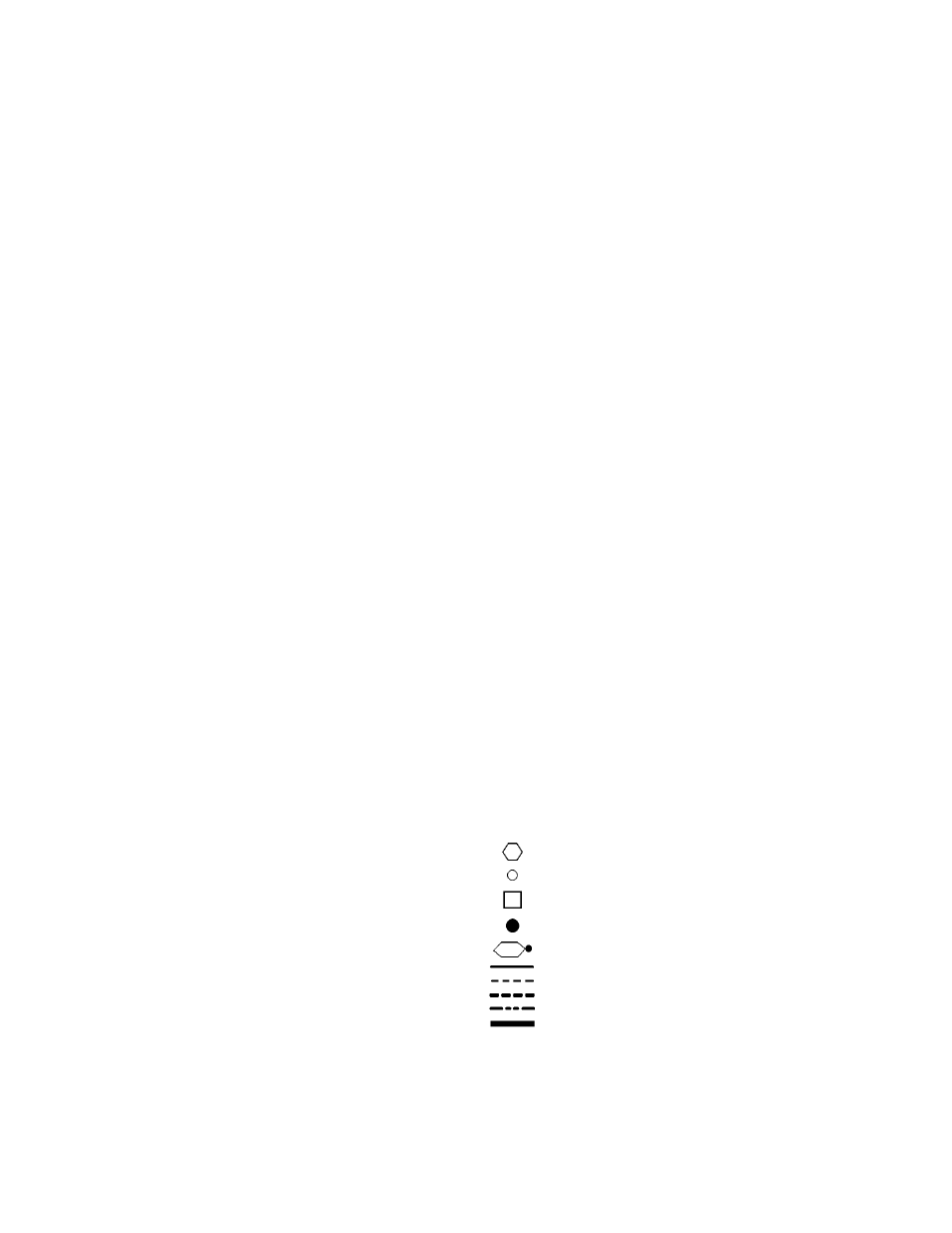

Terminal (Marked)

Terminal (Unmarked)

Terminal Block

Splice

Splice (Marked)

Factory Wiring

Field Control Wiring

Field Power Wiring

Accessory or Optional Wiring

To indicate common potential only; not to represent wiring.

20