Table 5 — condenser-fan performance – Bryant 502A User Manual

Page 6

—

6

—

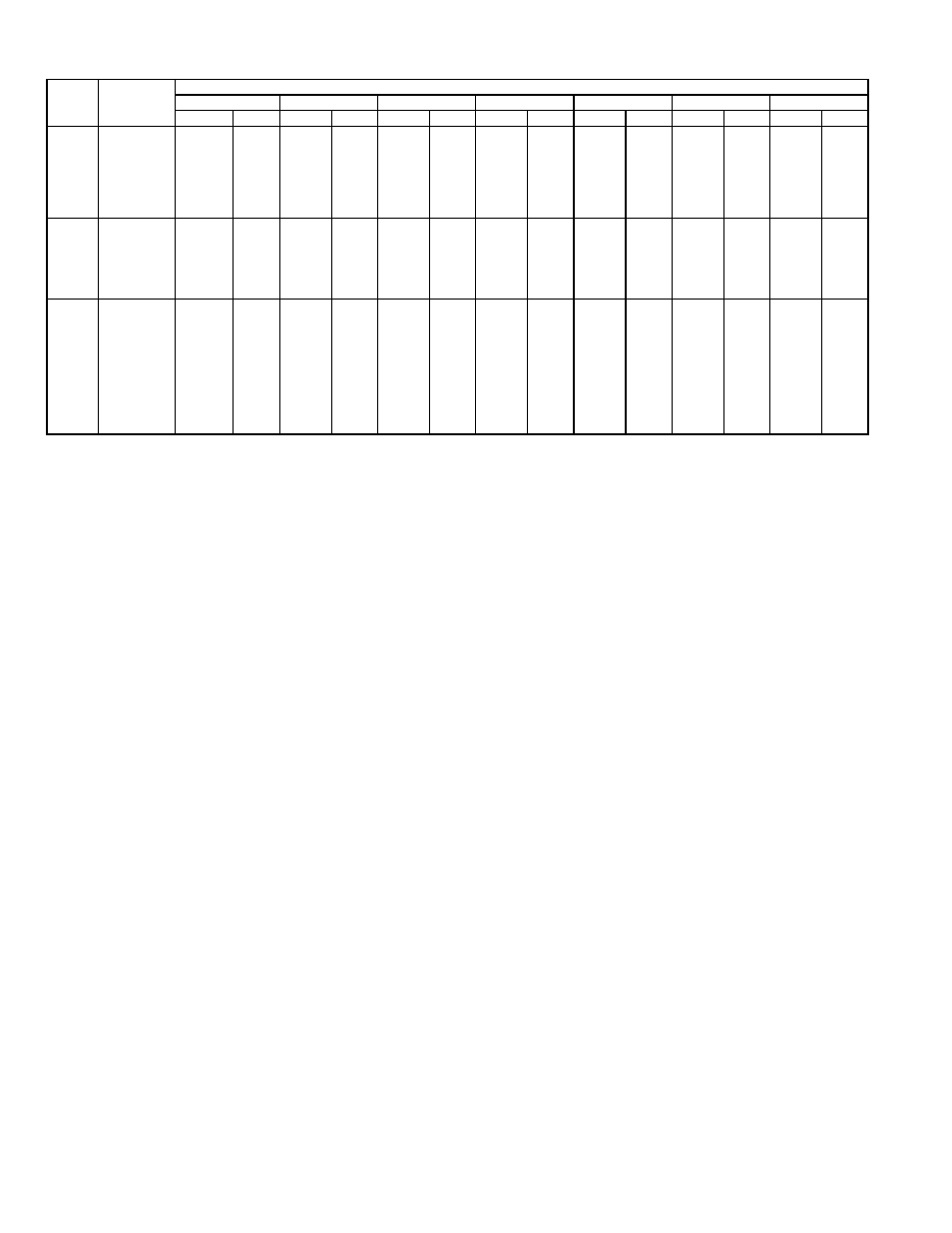

Table 5 — Condenser-Fan Performance

LEGEND

kW — Total Fan Motor Power Input (kilowatts)

NOTES:

1. Above fan performance is based upon coil and deducted casing losses only.

2. External static pressure (ESP) is measured in inches water gage (in. wg).

3. Interpolation is permissible. Do not extrapolate.

4. Minimum one turn open of motor pulley is required on unit sizes 036 and 060.

5. Number of turns open applies to field setting of motor pulley.

6. Factory setting as follows: 036, 4 turns open; 048, 2 turns open; 060, 5 turns

open.

START-UP

I. UNIT PREPARATION

Make sure unit has been installed in accordance with instal-

lation instructions and applicable codes.

II. COMPRESSOR MOUNTING

Compressors are internally spring mounted. Do not loosen or

remove compressor holddown bolts.

III. INTERNAL WIRING

Check all electrical connections in unit control boxes and

tighten as required. Be sure wires are not in contact with

sharp edges or refrigerant tubing.

IV. REFRIGERANT SERVICE VALVES

Each unit system has 3 Schrader-type service ports, one on

the suction line, one on the compressor discharge line, and

one for low-ambient damper kit. Be sure that caps on the

ports are tight. One Schrader-type valve is located under

both the high-pressure switch and low-pressure switch.

V. COMPRESSOR ROTATION

It is important to be certain compressor is rotating in the

proper direction. To determine whether or not compressor is

rotating in the proper direction:

1. Connect service gages to suction and discharge pres-

sure fittings.

2. Energize the compressor.

3. The suction pressure should drop and the discharge

pressure should rise, as is normal on any start-up.

If the suction pressure does not drop and the discharge pres-

sure does not rise to normal levels:

1. Note that the condenser fan may also be rotating in

the wrong direction.

2. Turn off power to the unit and tag disconnect.

3. Reverse any two of the unit power leads.

4. Reapply power to the unit; remove tag. Energize

compressor.

5. Verify correct refrigerant pressures.

The suction and discharge pressure levels should move to

their normal start-up levels.

NOTE: When the compressor is rotating in the wrong direc-

tion, the unit will sound louder than normal and will not

provide cooling.

VI. FAN ROTATION

Check fan rotation to ensure progression in proper direction.

VII. COOLING

To start unit, turn on main power supply. Set system selector

switch at COOL position and fan switch at AUTO. position.

Adjust thermostat to a setting below room temperature.

Compressor, condenser and evaporator motors start on clo-

sure of contactors.

A. To Shut Off Unit

Set system selector switch at OFF position or reset thermo-

stat at a position above room temperature. Units are

equipped with Cycle-LOC™ protective device.

Cycle-LOC™ device prevents an automatic restart of a unit’s

compressor that has been shut down due to a safety device

trip. The Cycle-LOC device may cause an indicator light on

the thermostat subbase to illuminate upon a safety trip (if

the thermostat includes this feature).

Be sure to check reason for safety trip before resetting the

Cycle-LOC device. Compressor restart is accomplished by

manual reset at the thermostat by first turning the selector

switch to OFF and then back to ON position.

UNIT

502A

AIRFLOW

(cfm)

EXTERNAL STATIC PRESSURE (in. wg)

0.0

0.1

0.2

0.3

0.4

0.5

0.6

Turns

kW

Turns

kW

Turns

kW

Turns

kW

Turns

kW

Turns

kW

Turns

kW

036

1650

2

.84

—

—

—

—

—

—

—

—

—

—

—

—

1600

—

—

2

.82

—

—

—

—

—

—

—

—

—

—

1550

—

—

—

—

2

.80

—

—

—

—

—

—

—

—

1500

3

.72

—

—

—

—

2

.78

1

.84

—

—

—

—

1450

4

.63

3

.70

—

—

—

—

2

.76

1

.83

—

—

1400

—

—

4

.61

3

.68

—

—

—

—

—

—

1

.81

1350

5

.51

—

—

—

—

3

.67

—

—

2

.73

—

—

1300

—

—

5

.50

4

.57

—

—

3

.65

—

—

2

.71

048

2700

2

.90

—

—

—

—

—

—

—

—

—

—

—

—

2600

—

—

2

.87

—

—

—

—

—

—

—

—

—

—

2550

3

.81

—

—

—

—

—

—

—

—

—

—

—

—

2450

—

—

3

.77

2

.83

1

.89

—

—

—

—

—

—

2350

—

—

—

—

—

—

2

.80

1

.86

—

—

—

—

2300

4

.68

—

—

3

.74

—

—

—

—

0

.90

—

—

2200

—

—

4

.66

—

—

—

—

2

.77

1

.82

0

.86

060

3100

3

1.34

—

—

—

—

—

—

—

—

—

—

—

—

3000

—

—

3

1.32

—

—

—

—

—

—

—

—

—

—

2900

—

—

—

—

—

—

2

1.39

—

—

—

—

—

—

2850

4

1.11

—

—

3

1.24

—

—

—

—

—

—

—

—

2750

—

—

4

1.07

—

—

—

—

2

1.32

—

—

—

—

2700

—

—

—

—

—

—

3

1.17

—

—

—

—

—

—

2650

—

—

—

—

—

—

—

—

—

—

—

—

1

1.37

2600

5

.95

—

—

4

1.01

—

—

—

—

2

1.26

—

—

2550

—

—

—

—

—

—

—

—

3

1.12

—

—

—

—

2500

—

—

5

.92

—

—

—

—

—

—

—

—

—

—

2450

—

—

—

—

—

—

4

.97

—

—

—

—

2

1.21

2400

—

—

—

—

5

.90

—

—

—

—

3

1.08

—

—