Bryant 502A User Manual

Page 5

—

5

—

6. Unsweat the cut portions of the refrigerant piping in

evaporator section at the closest bell joint. The bell

joints are used to connect field-supplied refrigerant

piping to evaporator section. Cut and braze a length

of tubing to extend refrigerant piping outside the

evaporator section.

7. Cut condenser-fan motor wiring at the partitions sep-

arating condenser and evaporator sections.

8. In the condenser section, install a junction box adja-

cent to the D-shaped grommet.

9. Install evaporator and condensing sections in desired

locations. Refer to Steps 10-12 below.

10. Use appropriate length of no. 16 American Wire Gage

(AWG) (minimum),

4

/

64

-in. insulated copper wire to

reconnect cut condenser-fan motor wires. Make con-

nections in junction boxes installed in earlier steps.

Follow all applicable electrical codes.

11. Use sufficient length of refrigerant piping to recon-

nect piping cut in previous step. Liquid line tubing is

3

/

8

-in. OD copper tubing, and hot gas line is

1

/

2

-in. OD

copper tubing.

12. Replace top panels on each section.

13. Evacuate refrigerant system to 500 microns.

14. Recharge unit with R-22 refrigerant following

Charging Charts (page 8) in these instructions. Use

refrigerant charge as indicated on unit.

NOTE: National Electric Code (NEC) disconnects are

required at each section if units are not installed within line

of sight of each other.

After splitting sections, additional refrigerant must be added

to system to ensure proper refrigerant charge. The amount of

refrigerant to be added depends on length of tubing added to

system and operating temperatures of system. Allow unit to

operate at least 10 minutes before adjusting refrigerant

charge.

Since standard roomtop unit has negligible line losses, split-

ting the system can increase line loss and decrease system

capacity.

IX. FIELD CONTROL WIRING

Install a Bryant-approved thermostat assembly accessory

according to installation instructions provided by thermostat

manufacturer. Locate thermostat assembly on a solid wall in

the conditioned space away from drafts to sense average

room temperature.

Using thermostat cable or equivalent single leads of no. 18

AWG colored wire, route cable or wire from the subbase ter-

minals, up and through connector on unit side (below power

lead junction box) and connect to low-voltage terminal block

inside the control box.

X. THERMOSTAT WIRE

Use 18 gage for 0 to 50 ft long wires and 16 gage for 51 to

75-ft wire lengths.

XI. STEP 8 — FAN SPEED

Adjust condenser fan speed and evaporator fan speed to meet

job requirements. Enter the condenser and evaporator sec-

tions through the hinged access panels on the bottom of

units (see Fig. 2). See Service section of this document for

general service procedures.

A. Evaporator-Fan Motors

Standard evaporator fans are direct-driven designs. Size 036

units have single-speed motors and require no adjustment.

Sizes 048 and 060 units use two-speed fan motors. Refer to

Table 3 for standard evaporator fan performance. The evapo-

rator fan motor factory speed selection is shown on the label

diagram affixed to base unit. If other than factory speed set-

ting is desired, refer to label diagram for motor reconnection.

Optional evaporator fan drives (for unit sizes 048 and 060)

are belt-drive designs. Refer to Table 4 for optional evapora-

tor fan performance. Adjust the motor pulley setting as

required to provide the project design evaporator airflow

rate. Pulley setting must limit the airflow rate to maximum

of 2250 cfm.

See Service section for instructions on checking motor shaft

and fan shaft alignment, pulley alignment and belt tension.

B. Condenser-Fan Motors

Condenser-fan motors are belt driven. Fan speed must be

adjusted to maintain condenser airflow at the flow rate

specified in Table 1. Refer to Table 5 for condenser fan per-

formance data. See Note 6 for factory drive pulley settings.

Adjust the motor pulley setting as required to provide design

condenser airflow through the site’s condenser duct system.

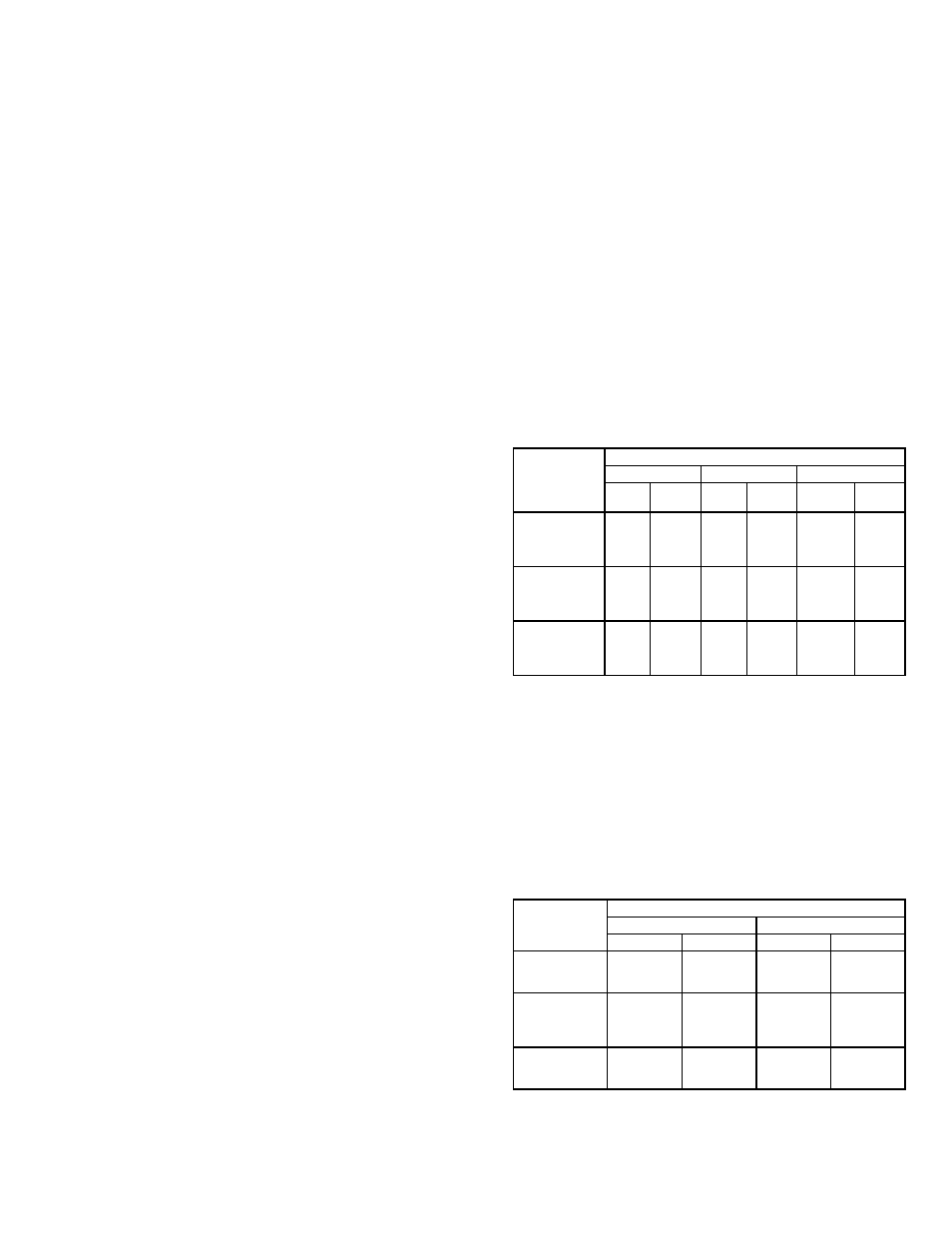

Table 3 — Evaporator-Fan Performance

LEGEND

*Standard direct drive indoor-fan motor (IFM). For optional belt drive

IFM performance, see following table.

NOTES:

1. Above fan performance is based on wet coil and deducted casing

losses, and clean factory-installed permanent cleanable filter.

2. Evaporator fans are direct drive (except sizes 048, 060 indoor-fan

motor option).

3. Interpolation is permissible, do not extrapolate.

Table 4 — Optional Belt-Drive

Evaporator-Fan Performance

NOTE: Pulley setting must be adjusted to limit cfm to 2250 cfm

maximum. Unit operation beyond that limit may result in blow-off and

condensate problems.

AIRFLOW

(cfm)

UNIT SIZE — 502A

036

048*

060*

ESP

Fan

kW

ESP

Fan

kW

ESP

Fan

kW

900

.69

.44

—

—

—

—

1000

.57

.46

—

—

—

—

1100

.42

.49

1.10

.45

1.11

.52

1200

.23

.52

1.01

.49

1.045

.55

1300

—

—

.90

.51

.97

.57

1400

—

—

.79

.55

.88

.59

1500

—

—

.67

.58

.78

.62

1600

—

—

.54

.61

.67

.64

1700

—

—

.39

.64

.53

.67

1800

—

—

.22

.67

.52

.70

1900

—

—

.03

.70

.40

.74

2000

—

—

—

—

.28

.78

ESP — External Static Pressure (in. wg)

kW

— Total Fan Motor Power Input (kilowatts)

AIRFLOW

(cfm)

UNIT SIZE — 502A

048

060

ESP

Fan kW

ESP

Fan kW

1800

—

—

—

—

1850

—

—

—

—

1900

—

—

—

—

1950

.81

1.03

—

—

2000

.72

1.05

—

—

2050

.63

1.07

—

—

2100

.55

1.08

1.02

1.17

2150

.47

1.11

.93

1.21

2200

.42

1.14

.84

1.24

2250

.34

1.17

.75

1.27