Trained service technician’s regular maintenance – Beckett FII 85 User Manual

Page 12

Page 12

RWB 6104 BAFII R01

Inspect the nozzle adapter before installing the

new nozzle. If it is grooved or scratched on the

sealing surface, replace the nozzle line assem-

bly. If the surface is damaged, oil could leak at

the nozzle to adapter joint, causing serious com-

bustion problems.

Protect the nozzle orifi ce and strainer when in-

stalling. If the orifi ce gets dirt in it or is scratched,

the nozzle will not function properly.

To install a new nozzle, place a

3/4

” open-end

wrench on the nozzle adapter. Insert the nozzle

into the adapter and secure fi nger tight. Finish

tightening with a 3/8” open-end wrench. Use care

to avoid bending the burner head support legs or

electrodes.

Do not over-torque the nozzle when install-

ing. This will cause deep grooves in the nozzle

adapter, preventing a seal when a new nozzle is

installed.

Carefully check and realign the electrode tips af-

ter replacing a nozzle, ensuring the electrode set-

tings comply with Figure 6a or 6b.

If the head was removed when replacing the

nozzle, carefully reconnect the head to the noz-

zle adapter. Push the head support until it stops

against the nozzle shoulder. Verify the dimen-

sion between the nozzle face and the back of the

head is 5/32”.

5.

6.

7.

8.

9.

10.

Check/Adjust Electrodes

Check the electrode tip settings, as shown in Figure

6a or 6b. If necessary, adjust by loosening the elec-

trode clamp screw and slide/rotate the electrodes

as necessary. When the adjustment is complete,

securely tighten the clamp screw.

•

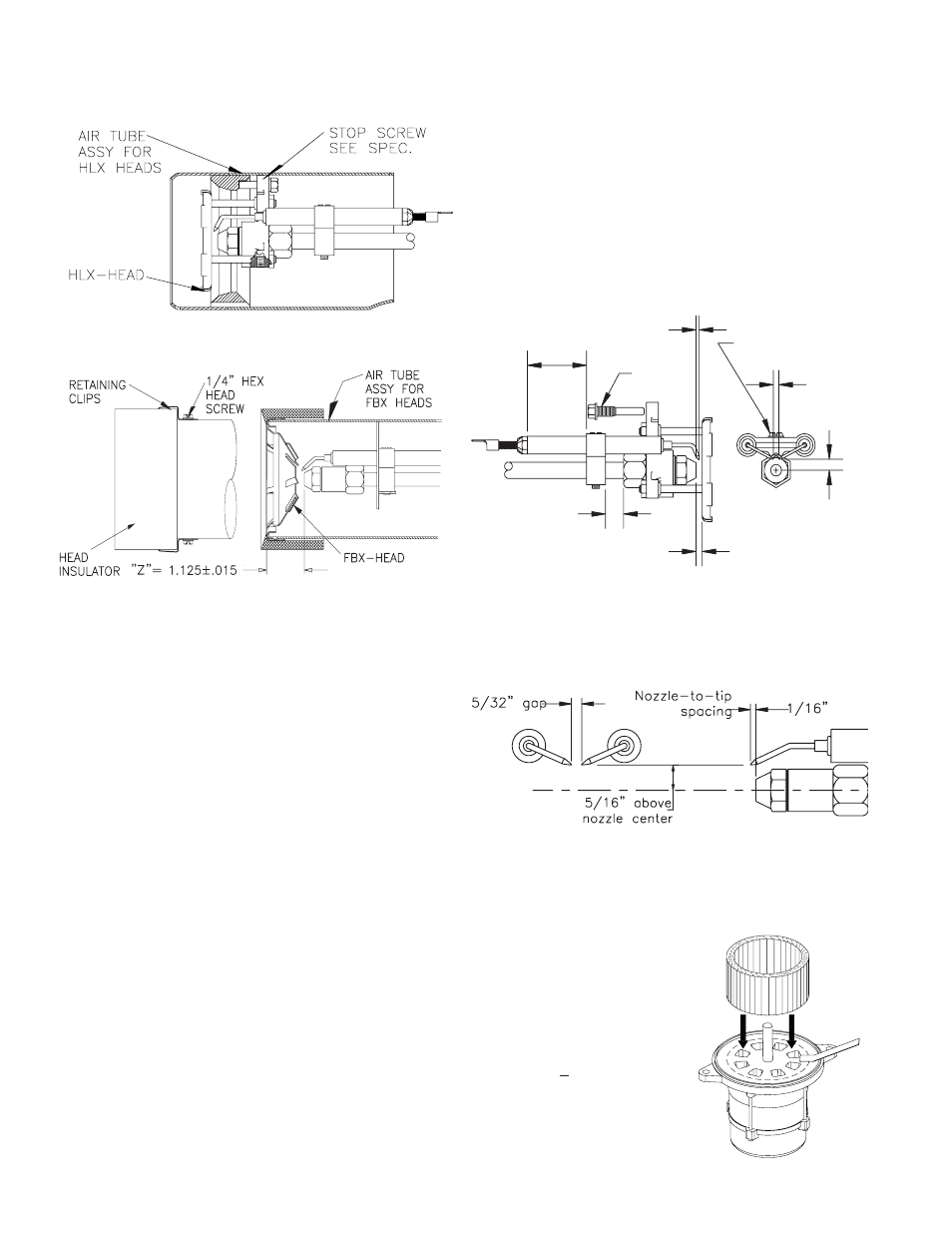

Figure 5a. HLX Air Tube

Figure 5b. FBX Air Tube

SK9639

Trained Service Technician’s Regular Maintenance

SK9641

Blower Wheel Re-

placement

For installation or re-

placement of a blower

wheel, insure that there

is a space between the

blower wheel and the

motor face of 0.062”

(1/16” + 1/64”). Refer to

Figure 7.

•

Figure 6a. Electrode Settings-HLX Air Tube Com-

binations

1-1/2”

15/32”

3/32”

5/32”

1/4”

5/32”

Nozzle face to back of head

Stop

Screw

Do NOT overtighten

Clamp Screw

SK8263

Figure 6b. Electrode Settings-FBX Air Tube Com-

binations

SK9461

Figure 7. – Blower

Wheel Replacement

SK9190A