Bryant Air Cooled Condensing Units 569C User Manual

Page 7

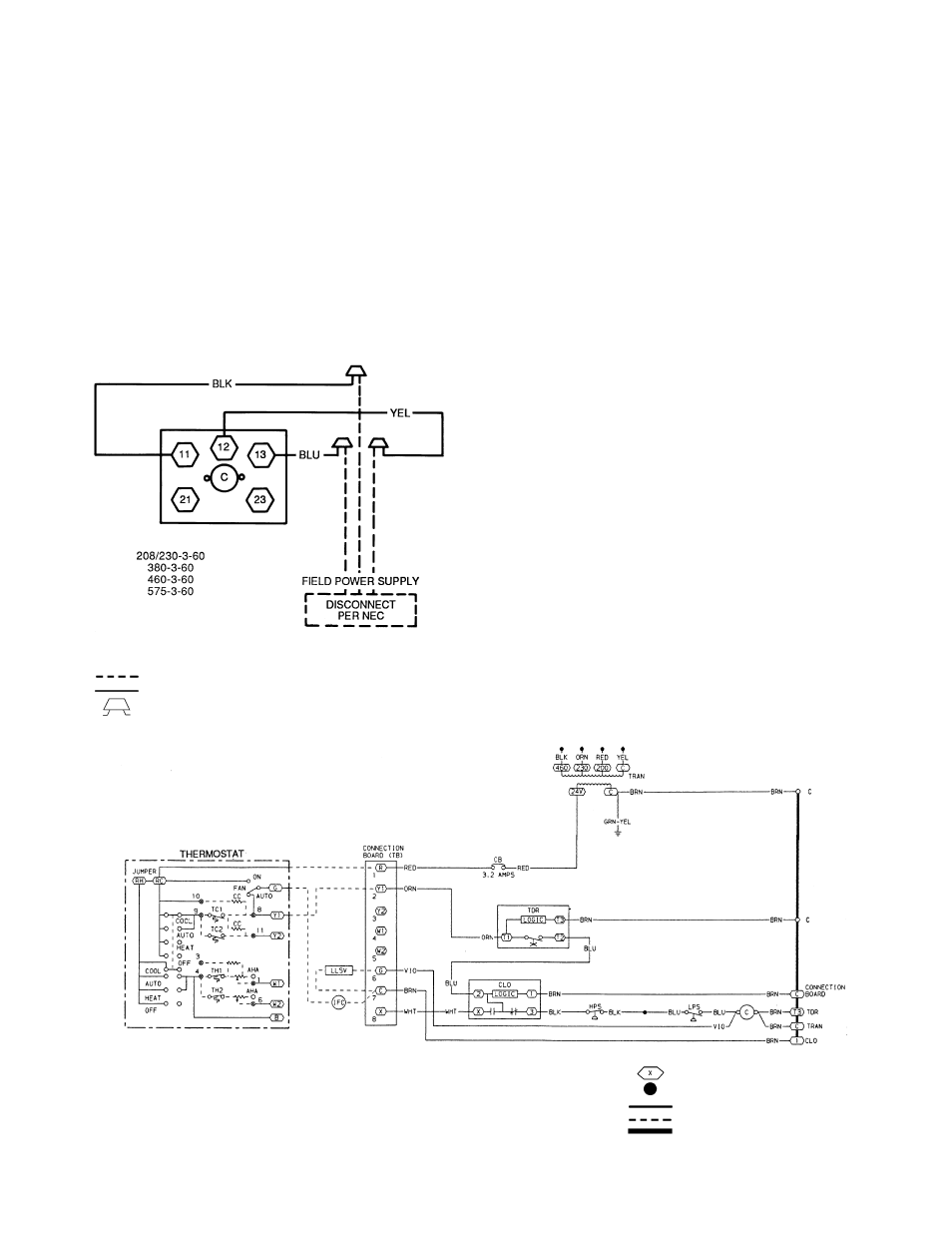

All units except 208/230-v units are factory wired for the volt-

age shown on the nameplate. If the 208/230-v unit is to be

connected to a 208-v power supply, the transformer must be

rewired by moving the black wire from the 230-v orange wire

on the transformer and connecting it to the 200-v red wire

from the transformer. The end of the orange wire must then

be insulated.

Refer to unit label diagram for additional information. Pig-

tails are provided for field wire connections. Use factory-

supplied splices or UL (Underwriters’ Laboratories) approved

copper/aluminum connector.

When installing units, provide a disconnect per NEC.

All

field

wiring

must

comply

with

NEC

and

local

requirements.

Install field wiring as follows:

1. Install conduit through side panel openings.

2. Install power lines to terminal connections as shown in

Fig. 6.

B. Control Voltage Connections

Install an accessory thermostat assembly according to instal-

lation instructions included with the accessory. Locate ther-

mostat assembly on a solid wall in the conditioned space to

sense average temperature in accordance with thermostat

installation instructions.

Route thermostat cable or equivalent single leads of colored

wire from subbase terminals to low-voltage connections on

unit (shown in Fig. 7) as described in Steps 1 through 4

below.

NOTE:

Refer to Table 5 for wire conversion information.

NOTE:

For wire runs up to 50 ft (15.2 m), use no. 18 AWG

(0.82 mm) insulated wire (35 C minimum). For 50 to 75 ft

(15.2 to 22.9 m), use no. 16 AWG (1.30 mm) insulated wire

(35 C minimum). For over 75 ft (22.9 m), use no. 14 AWG

(2.08 mm) insulated wire (35 C minimum). All wire larger

than no. 18 AWG (0.82 mm) cannot be directly connected to

the thermostat and will require a junction box and splice at

the thermostat.

1. Connect thermostat wires to screw terminals of low volt-

age connection board.

2. Pass the control wires through the hole provided in the

corner post. See Fig. 8.

3. Feed wire through raceway built into the corner post

and into the 24-v thermostat connection board. The 24-v

thermostat connection is located on the left side of the

low voltage connection compartment. The raceway pro-

vides the UL required clearance between the high- and

low-voltage wiring.

4. Total combined amperage draw of the field-installed liq-

uid line solenoid valve and indoor fan contactor must

not exceed 22 va. If the specified va must be exceeded,

use a remote relay to switch the load.

LEGEND

C

— Contactor

NEC — National Electrical Code (U.S.A. Standard)

Field Wiring

Factory Wiring

Splice Connection (Factory Supplied)

Fig. 6 — Power Wiring Connections

LEGEND

AHA — Adjustable Heat Anticipator

C

— Contactor, Compressor

CB

— Circuit Breaker

CC

— Cooling Compensator

CLO — Compressor Lockout

HPS — High-Pressure Switch

IFC

— Indoor (Evaporator) Fan Contactor

Fig. 7 — Typical Control Wiring Connections (569C Shown)

LLSV

— Liquid Line Solenoid Valve

LPS

— Low-Pressure Switch

TB

— Terminal Block

TC

— Thermostat-Cooling

TDR

— Time-Delay Relay

TH

— Thermostat-Heating

TRAN — Transformer

Terminal (Marked)

Splice

Factory Wiring

Field Control Wiring

To Indicate Common Potential Only,

Not To Represent Wiring

—7—