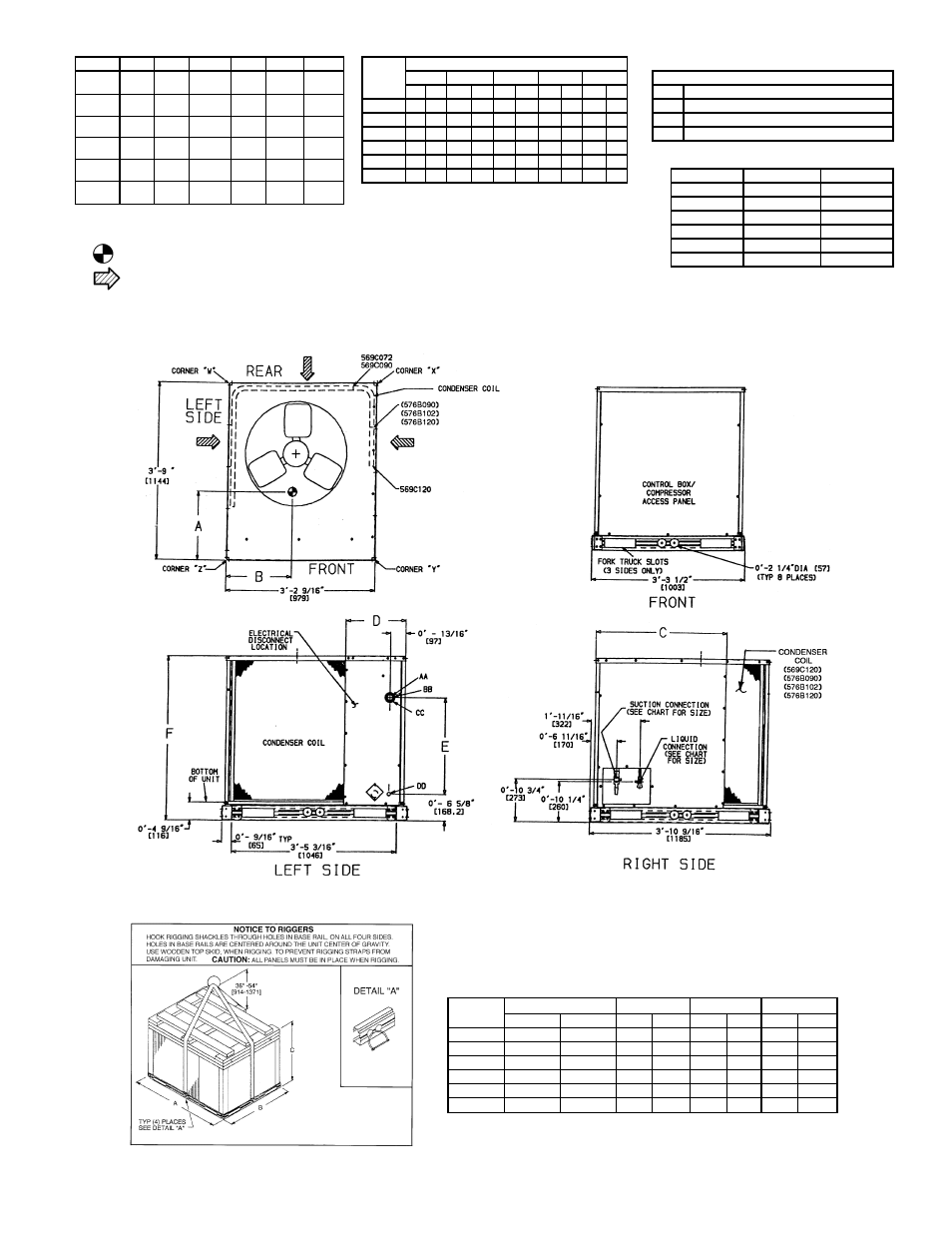

Fig. 3 — base unit dimensions, Fig. 4 — rigging label —5 – Bryant Air Cooled Condensing Units 569C User Manual

Page 5

UNIT

DIM. A DIM. B

DIM. C

DIM. D DIM. E

DIM. F

569C072

1

Ј

-6

1

⁄

2

Љ

1

Ј

-2

3

⁄

4

Љ

—

1

Ј

-2

1

⁄

4

Љ

1

Ј

-4

5

⁄

16

Љ

2

Ј

-9

5

⁄

16

Љ

[470.0] [375.0]

—

[362]

[415]

[846.5]

569C090

1

Ј

-8

Љ

1

Ј

-6

1

⁄

2

Љ

—

1

Ј

-3

Љ

2

Ј

-

5

⁄

16

Љ

3

Ј

-5

7

⁄

16

Љ

[508.0] [470.0]

—

[381]

[613]

[1052.5]

569C120

1

Ј

-9

Љ

1

Ј

-8

Љ

2

Ј

-0

Љ

1

Ј

-3

Љ

2

Ј

-

5

⁄

16

Љ

3

Ј

-5

7

⁄

16

Љ

[533.4] [508.0]

[609.6]

[381]

[613]

[1052.5]

576B090

1

Ј

-6

Љ

1

Ј

-4

3

⁄

4

Љ

2

Ј

-9

13

⁄

16

Љ

1

Ј

-3

Љ

2

Ј

-

5

⁄

16

Љ

3

Ј

-5

7

⁄

16

Љ

[457.2] [425.5]

[858.8]

[381]

[613]

[1052.5]

576B102

1

Ј

-7

Љ

1

Ј

-5

Љ

2

Ј

-9

13

⁄

16

Љ

1

Ј

-3

Љ

2

Ј

-

5

⁄

16

Љ

3

Ј

-5

7

⁄

16

Љ

[482.6] [431.8]

[858.8]

[381]

[613]

[1052.5]

576B120

1

Ј

-7

Љ

1

Ј

-5

Љ

2

Ј

-9

13

⁄

16

Љ

1

Ј

-3

Љ

2

Ј

-

5

⁄

16

Љ

3

Ј

-5

7

⁄

16

Љ

[482.6] [431.8]

[858.8]

[381]

[613]

[1052.5]

ELECTRICAL CONNECTIONS

CONNECTION SIZES

AA

1

3

⁄

8

Љ

DIA [35] FIELD POWER SUPPLY HOLE

BB

2

Љ

DIA [51] POWER SUPPLY KNOCK-OUT

CC

2

1

⁄

2

Љ

DIA [64] POWER SUPPLY KNOCK-OUT

DD

7

⁄

8

Љ

DIA [22] FIELD CONTROL WIRING HOLE

SERVICE VALVE CONNECTIONS — 60 Hz

UNIT

SUCTION

LIQUID

569C072

1

1

⁄

8

Љ

[28.6]

1

⁄

2

Љ

[12.7]

569C090

1

1

⁄

8

Љ

[28.6]

1

⁄

2

Љ

[12.7]

569C120

1

1

⁄

8

Љ

[28.6]

5

⁄

8

Љ

[15.9]

576B090

1

1

⁄

8

Љ

[28.6]

1

⁄

2

Љ

[12.7]

576B102

1

1

⁄

8

Љ

[28.6]

5

⁄

8

Љ

[15.9]

576B120

1

1

⁄

8

Љ

[28.6]

5

⁄

8

Љ

[15.9]

NOTES:

1. Dimensions in [ ] are in millimeters.

2.

Center of Gravity. See chart for dimensions.

3.

Direction of Airflow.

4. Minimum clearance (local codes or jurisdiction may prevail):

a. Condenser coil, for proper airflow, 36 in. [914] one side, 12 in. [305]

the other. The left or rear side getting the greater clearance is optional.

b. Overhead, 60 in. [1524] to assure proper condenser fan operation.

c. Between units, control box side, 42 in. [1067]

per NEC (National Electrical Code) (U.S.A.

Standard).

d. Between unit and ungrounded surfaces, con-

trol box side, 36 in. [914] per NEC.

e. Between unit and block or concrete walls and

other grounded surfaces, control box side,

42 in. [1067] per NEC.

5. With the exception of the clearance for the con-

denser coil as stated in note 4b, a removable

fence or barricade requires no clearance.

6. Units may be installed on combustible floors made

from wood or Class A, B, or C roof covering

material.

UNIT

WEIGHT CHART*

Std Unit Corner W Corner X Corner Y Corner Z

Lb Kg

Lb

Kg

Lb

Kg

Lb

Kg

Lb

Kg

569C072 340 154

86

39

53

24

77

35

124

56

569C090 370 168

86

39

78

35

99

45

107

49

569C120 395 179

89

40

92

42

109

49

105

48

576B090 510 231 115

52

89

40

133

60

173

87

576B102 564 256 133

60

97

44

141

64

193

88

576B120 564 256 133

60

97

44

141

64

193

88

*Weights are for aluminum coils.

Fig. 3 — Base Unit Dimensions

UNIT

RIGGING WEIGHT*

A

B

C

lb

kg

in.

mm

in.

mm

in.

mm

569C072

390

176

45.0

1143

38.5

978

35.5

904

569C090

420

191

45.0

1143

38.5

978

43.5

1105

569C120

445

202

45.0

1143

38.5

978

43.5

1105

576B090

560

254

45.0

1143

38.5

978

43.5

1105

576B102

614

279

45.0

1143

38.5

978

43.5

1105

576B120

614

279

45.0

1143

38.5

978

43.5

1105

*Weights are for aluminum coils.

Fig. 4 — Rigging Label

—5—