Mechanical problems – Brother PE 150 User Manual

Page 67

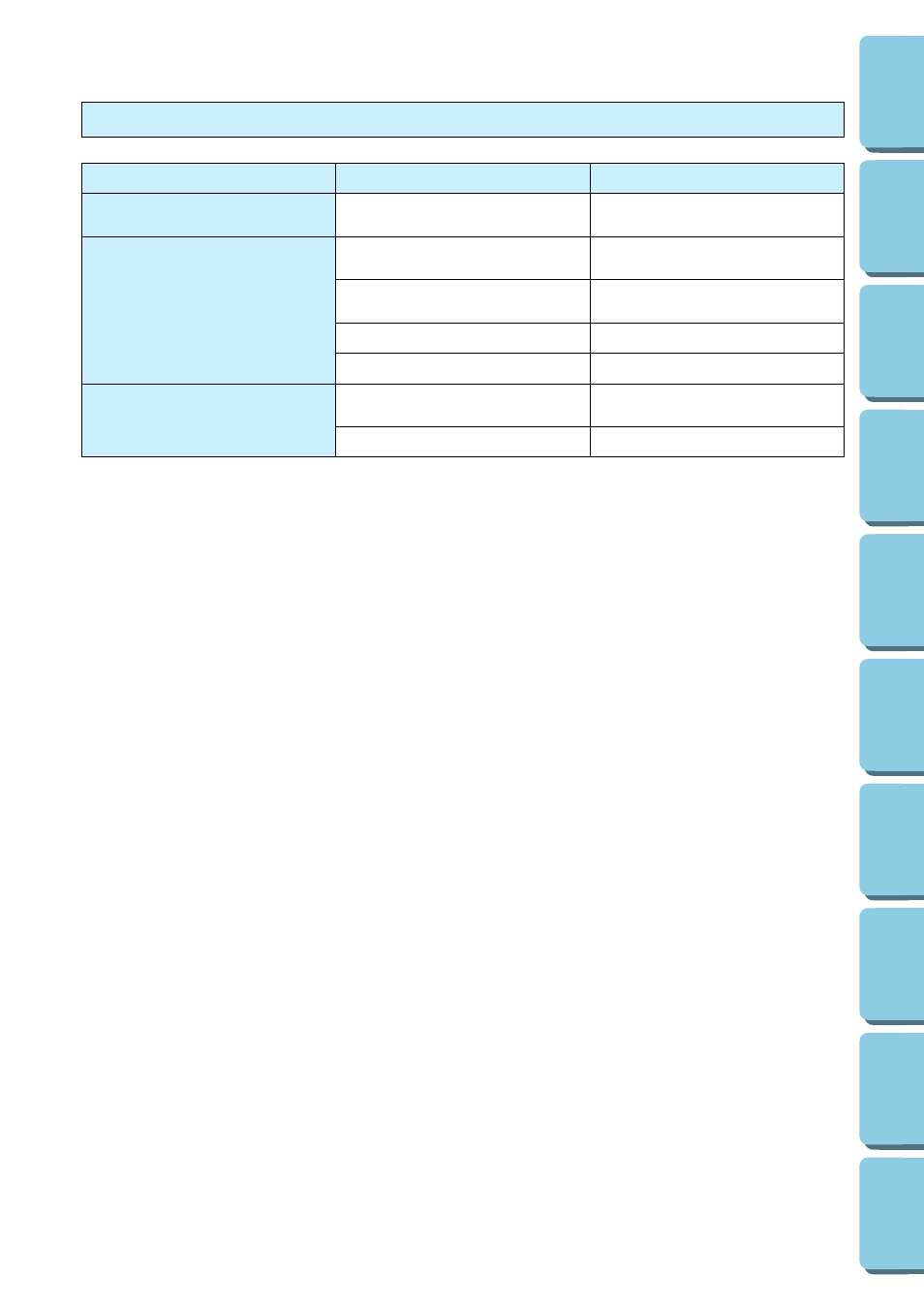

Symptom

1. Machine operation is slow and

noisy

2. The machine does not start

3. The needle breaks

64

Mechanical problems

Probable cause

1. Thread scraps and dust have

accumulated under the needle plate.

1. The “START/STOP” button is not

pressed.

2. The main power switch is in the off

position.

3. The presser foot is not lowered.

4. Check Error messages.

1. The needle is not correctly inserted.

2. The correct needle is not used.

Remedy

1. Remove the thread scraps and dust

with a brush.

1. Press the “START/STOP” button.

2. Turn the power on.

3. Lower the presser foot.

4. See “ERROR MESSAGE” on page 59.

1. Remove the needle and reset a new

needle properly.

2. Change to the proper needle.

Caution

●

This machine is equipped with a thread breakage sensor. Accordingly, if the upper thread is

not threaded, the machine will not operate even if the “START/STOP” button is pressed.

In addition, a loud noise which is different from the normal operation noise is generated by the

needle bar holding mechanism during layout changes, layout change tests and also when the

embroidery frame travels a lot during embroidery. This sound is normal and is not the result of

a malfunction.

●

If the power goes off during embroidering:

●

Turn the power off and unplug the machine. Damage may occur if the machine is on when

the power comes back on.

●

To start again, while the main power switch is off, plug the unit in. Then turn the main power

switch on and select an operation. Refer to page 54, using the “HELP” function to get back

to the point where the machine went off.