Warning, Shock hazard – Bloomfield 9010 User Manual

Page 7

INSTALLATION INSTRUCTIONS (continued)

NOTE: This equipment must be

installed to comply with

applicable federal, state and

local plumbing codes and

ordinances.

WARNING:

SHOCK HAZARD

Brewer must be properly

grounded to prevent possible

shock hazard. DO NOT

assume a plumbing line will

provide such a ground.

Electrical shock will cause death

or serious injury.

IMPORTANT: Do not connect

brewer to electrical power until

the tank is filled with water.

Pour water into the pour-over

opening until water flows from

the brew head.

IMPORTANT:

Supply power must match

nameplate for voltage and

phase. Connecting to the

wrong voltage will damage the

brewer or result in decreased

performance. Such damage is

not covered by warranty.

In some areas, local codes require a backflow preventer (check

valve) to be installed on the inlet water line. If a backflow

preventer is used, you must install a water hammer arrester in

the incoming line, between the backflow preventer and the

brewer inlet, as far away from the brewer as space will allow.

This will relieve the excessive back pressures that can cause

faucet leaks and solenoid malfunctions.

ELECTRICIAN’S INSTALLATION INSTRUCTIONS

REFER TO ELECTRICAL SPECIFICATIONS - Page 1

Check the nameplate to determine correct electrical service

required for the brewer to be installed.

IMPORTANT: Before connecting to electricity, make sure

automatic brewers are connected to the water supply.

Models 9010 & 9012 are equipped with a cord and plug. They

require a 115 - 125 volt 20 amp circuit (50/60 Hz, 2 wire plus

ground, with NEMA 5-15R or 5-20R Receptacle).

IMPORTANT: The ground prong of the plug is part of a system

designed to protect you from electrical shock in the event of

internal damage. Never cut off the ground prong nor twist a

blade to fit an existing receptacle. Contact a licensed electrician

to install the proper circuit and receptacle.

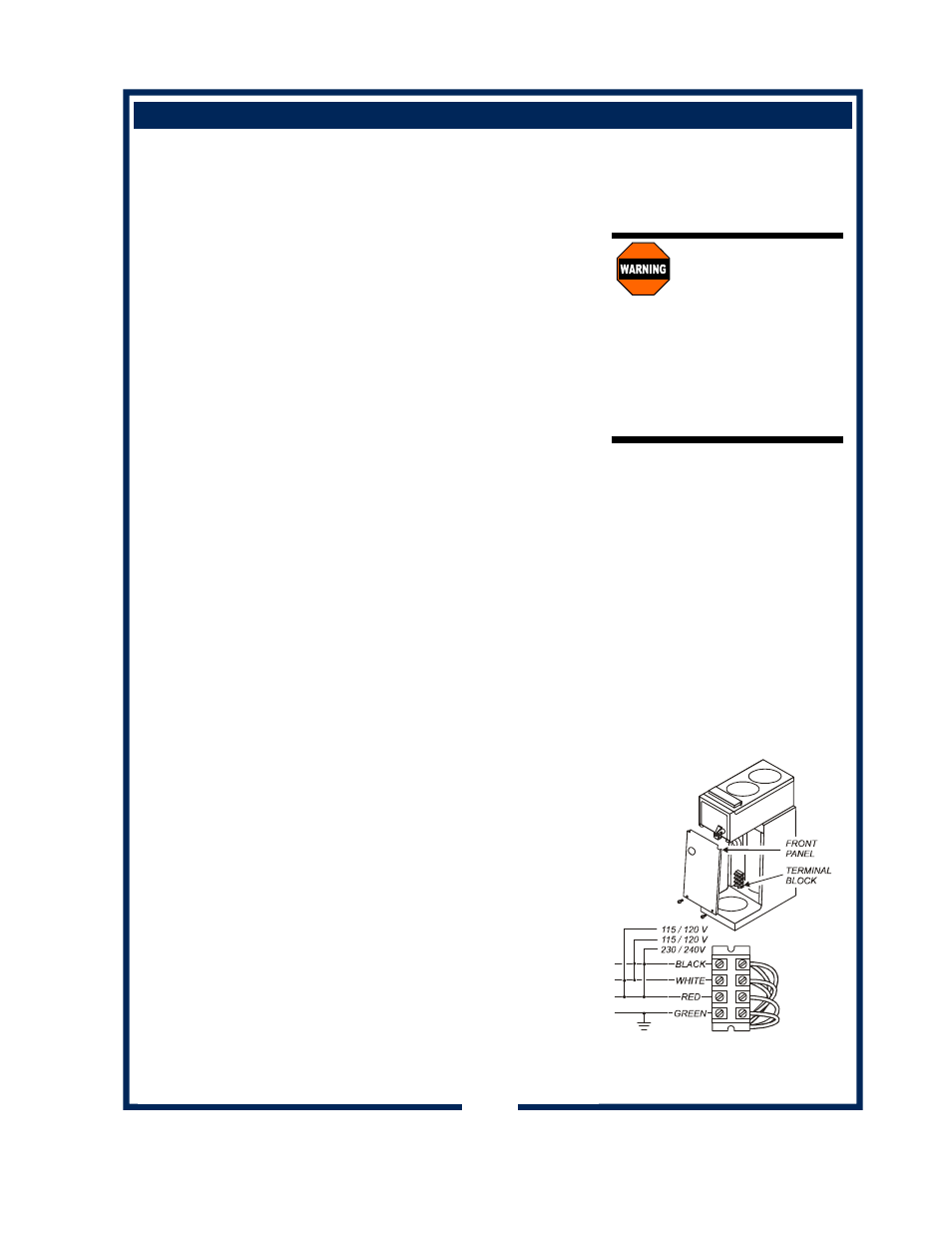

Models 9016 must be wired by an electrician, and require a

115/230V 20A circuit (50/60 Hz, 2 hot legs / 1 neutral leg, plus

ground). Remove front panel to gain access to terminal block.

Green terminal must be connected to a suitable building ground.

Circuit must be capable of 3800 Watts. See figure 3 at right.

IMPORTANT: Wiring must be installed in approved solid or

flexible conduit, and must be secured to the brewer with a strain

relief (to be provided by the installer).

Models 9016EX must be wired by an electrician, and require

a 220-240V 20A circuit (50/60 Hz, 2 hot legs plus ground).

Remove front panel to gain access to terminal block. Green

terminal must be connected to a suitable building ground.

Circuit must be capable of 3800 Watts. Refer to 9016EX wiring

diagram on page 23.

IMPORTANT: Wiring must be installed in accordance with local

codes and ordinances.

Fig. 3 115/240 Volt Terminal Block

5

601

75815

Owner

s

M

anual In

tegri

ty Decante

r

B

rewers