Bryant 350MAV User Manual

Page 26

WARNING:

Inducer housing outlet cap must be in-

stalled and fully seated against inducer housing. Clamp

must be tightened to prevent any condensate leakage.

Failure to follow this warning could result in electrical

shock, fire, personal injury, or death.

c. Install pipe support (factory-supplied in loose parts bag)

into selected furnace casing vent pipe hole. Pipe support

should be positioned at bottom of casing hole.

d. Insert 2-in. diameter pipe into inducer housing through

neoprene coupling and clamp in inducer housing.

Tighten clamp.

WARNING:

Vent pipe must be installed and fully

seated against inducer housing. Clamp must be tightened

to prevent any condensate leakage. Failure to follow this

warning could result in electrical shock, fire, personal

injury, or death.

NOTE:

A 2-in. diameter pipe must be used within the furnace

casing. Make all pipe diameter transitions outside furnace casing.

VENT EXTENSION PIPE

Furnaces with 100,000 Btuh and larger inputs are supplied

with a PVC vent extension pipe (2-in. diameter by 12-in.

long). This pipe has a built-in channel to assist vent

condensate disposal. When this vent extension pipe is

supplied, it must be used to connect the field vent pipe to

furnace inducer housing on ALL upflow and downflow

applications.

NOTE:

See label on vent extension pipe for proper installation.

This pipe may be shortened if an elbow is used to connect vent

extension tube to field-installed vent pipe.

3. Working from furnace to outside, cut pipe to required

length(s).

4. Deburr inside and outside of pipe.

TABLE 6—MAXIMUM ALLOWABLE PIPE LENGTH (FT)

Continued

ALTITUDE

UNIT SIZE

TERMINATION

TYPE

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

1

2

3

4

5

6

8001 to 9000‡

024040

036040

2 Pipe or 2-In.

Concentric

1-1/2

46

41

36

31

29

24

2

62

60

58

56

55

53

024060

036060

048060

2 Pipe or 2-In.

Concentric

1-1/2

11

6

NA

NA

NA

NA

2

49

44

42

37

35

34

036080

048080

060080

2 Pipe or 2-In.

Concentric

2

33

28

17

12

10

NA

2-1/2

62

60

58

56

55

53

048100

060100

2 Pipe or 3-In.

Concentric

2-1/2

23

15

7

5

NA

NA

3

59

54

49

44

39

34

→

060120

2 Pipe or 3-In.

Concentric

3† no disk

10

NA

NA

NA

NA

NA

4† no disk

35

30

25

20

15

10

→

060140

NA

ALTITUDE

UNIT SIZE

TERMINATION

TYPE

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

1

2

3

4

5

6

9001 to 10,000‡

024040

036040

2 Pipe or 2-In.

Concentric

1-1/2

42

37

32

27

25

20

2

57

55

53

51

49

47

024060

036060

048060

2 Pipe or 2-In.

Concentric

2

45

40

38

33

31

29

036080

048080

060080

2 Pipe or 2-In.

Concentric

2

30

25

14

9

7

NA

2-1/2

57

55

53

51

49

47

048100

060100

2 Pipe or 3-In.

Concentric

2-1/2

21

13

5

NA

NA

NA

3

54

49

44

39

34

29

→

060120

2 Pipe or 3-In.

Concentric

4† no disk

10

5

NA

NA

NA

NA

→

060140

NA

* Disk usage—Unless otherwise specified, use perforated disk assembly (factory-supplied in loose parts bag). If one disk is stated, separate 2 halves of perforated disk

assembly and use shouldered disk half. When using shouldered disk half, install screen side toward inlet box.

† Wide radius elbow.

‡ Vent sizing for Canadian installations over 4500 ft (1370 m) above sea level are subject to acceptance by the local authorities having jurisdiction.

NA—Not Allowed; pressure switch will not make.

NOTES:

1. Do not use pipe size greater than those specified in table or incomplete combustion, flame disturbance, or flame sense lockout may occur.

2. Size both the combustion-air and vent pipe independently, then use the larger diameter for both pipes.

3. Assume two 45° elbows equal one 90° elbow. Long radius elbows are desirable and may be required in some cases.

4. Elbows and pipe sections within the furnace casing and at the vent termination should not be included in vent length or elbow count.

5. The minimum pipe length is 5 ft for all applications.

6. Use 3-in. diameter vent termination kit for installations requiring 4-in diameter pipe.

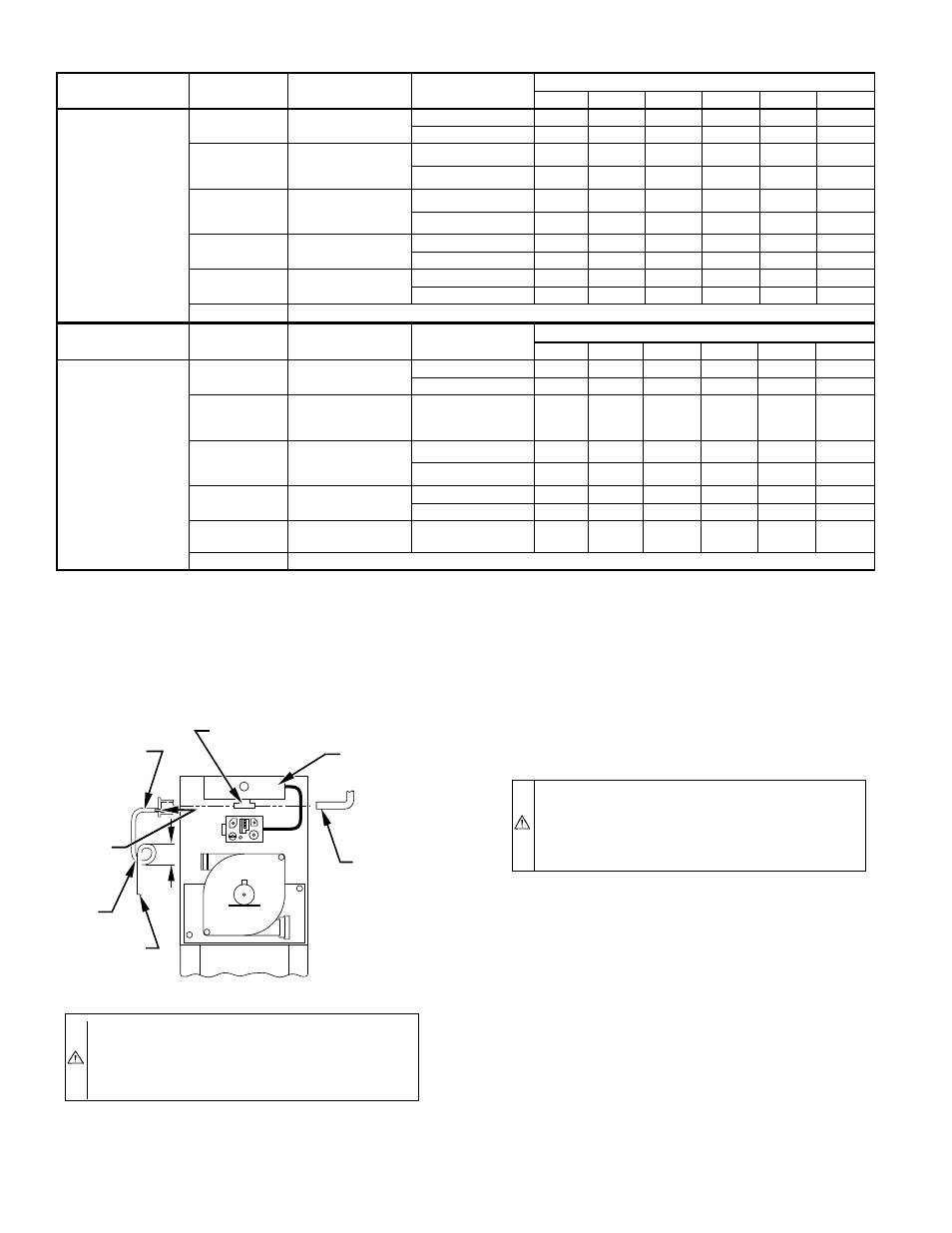

Fig. 30—Intake Housing Plug Fitting Drain

A93035

COMBUSTION –

AIR PIPE

BURNER

BOX

COMBUSTION – AIR

INTAKE HOUSING

3/8" ID TUBE

TRAP

TO OPEN

DRAIN

3/16"

DRILL

4

″

MIN

—26—

→