Bryant 350MAV User Manual

Page 22

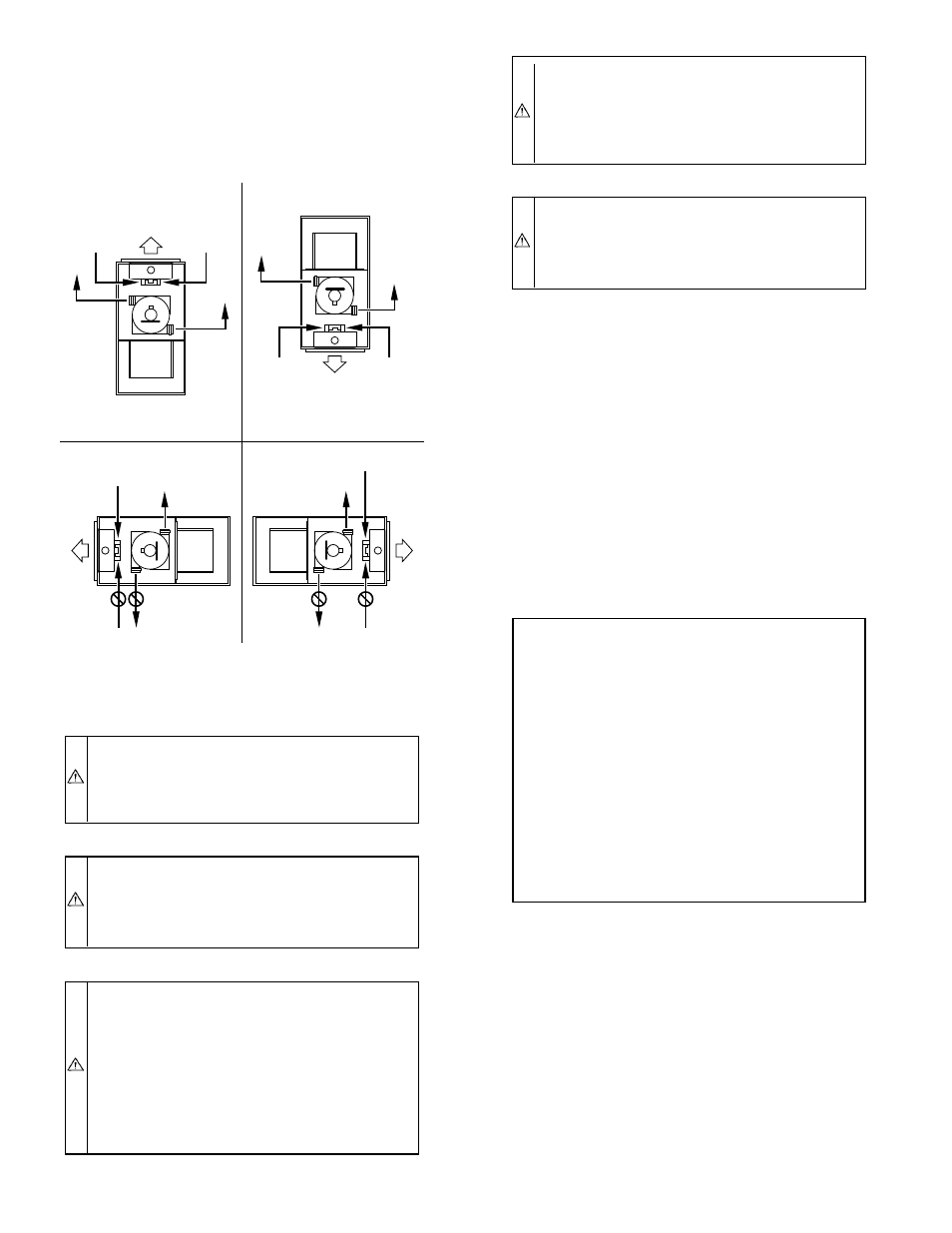

Furnace combustion-air and vent pipe connections must be at-

tached as shown in Fig. 28. Combustion-air intake plug fitting and

inducer housing alternate vent cap may need to be relocated in

some applications.

NOTE:

Slope combustion-air and vent pipes a minimum of 1/4

in. per linear ft with no sags between hangers.

CAUTION:

When combustion-air pipe is installed

above a suspended ceiling, pipe must be insulated with

3/8-in. thick Armaflex-type insulation. Combustion-air

pipe should also be insulated when it passes through

warm, humid space.

CAUTION:

When vent pipe is exposed to temperatures

below freezing, such as when it passes through an

unheated space or when a chimney is used as a raceway,

pipe must be insulated as shown in Table 7 with

Armaflex-type insulation.

CAUTION:

Combustion air must not be taken from

inside structure because inside air is frequently contami-

nated by halogens, which include fluorides, chlorides,

bromides, and iodides. These elements are found in

aerosols, detergents, bleaches, cleaning solvents, salts, air

fresheners, adhesives, paint, and other household prod-

ucts. Locate combustion-air inlet as far as possible from

swimming pool and swimming pool pump house.

Excessive exposure to contaminated combustion air will

result in safety and performance related problems.

WARNING:

Solvent cements are combustible. Keep

away from heat, sparks, and open flame. Use only in

well-ventilated areas. Avoid breathing in vapor or allow-

ing contact with skin or eyes. Failure to follow this

warning could result in fire, property damage, personal

injury, or death.

WARNING:

All combustion-air and vent pipes must be

airtight and watertight. Pipes must also terminate exactly

as shown in Fig. 31, 32, 33, 34, or 35. Failure to follow

this warning could result in property damage, personal

injury, or death.

NOTE:

The minimum combustion-air and vent pipe length (each)

for these furnaces is 5 ft. Short pipe lengths (5-8 ft) may discharge

water droplets. These droplets may be undesirable, and a 12-in.

minimum offset pipe section is recommended, as shown in Fig. 29,

to reduce excessive droplets from exiting vent pipe outlet.

B.

Combustion-Air and Vent Pipe Diameter

Determine combustion-air and vent pipe diameter.

1. Using Table 6, individually determine the combustion-air

and vent pipe diameters. Pick the larger of these 2 pipe

diameters and use this diameter for both combustion-air and

vent pipes.

2. When installing vent systems of short pipe length, use the

smallest allowable pipe diameter. Do not use pipe size

greater than required or incomplete combustion, flame

disturbance, or flame sense lockout may occur.

NOTE:

Do not count elbows or pipe sections in terminations or

within furnace. See shaded areas in Fig. 31, 32, 33, 34, and 35.

EXAMPLE:

An 036080 size furnace located in Indianapolis, elevation

650 ft above sea level, could be installed in an application

requiring 3 elbows and 32 ft of vent pipe, along with 5

elbows and 34 ft of combustion-air pipe. Table 6 indicates

this application would allow a 2-in. diameter vent pipe, but

require a 2-1/2 in. diameter combustion air pipe (2-in. pipe

is good for 35 ft with 3 elbows, but only 30 ft with 5

elbows). Therefore, 2-1/2 in. diameter pipe must be used

for both vent and combustion-air pipes since larger required

diameter must always be used for both pipes. If same

installation were in Albuquerque, elevation 5250 ft above

sea level, installation would require 2-1/2 in. vent pipe and

combustion-air pipe. At 5001- to 6000-ft elevation, 2-in.

pipe is only good for 17 ft with 5 elbows, and 2-1/2 in. pipe

is good for 70 ft with 5 elbows.

C.

Combustion-Air and Vent Pipe Attachment

NOTE:

All pipe joints must be watertight except attachment of

combustion-air pipe to inlet housing connection, since it may be

necessary to remove pipe for servicing.

1. Attach combustion-air pipe as follows:

a. Determine location of combustion-air intake pipe con-

nection to combustion-air intake housing as shown in

Fig. 28 for application.

b. Reposition combustion-air intake housing plug fitting in

appropriate unused intake housing connection.

c. If required, insert perforated disk assembly (factory-

supplied in loose parts bag) in intake housing where

combustion-air intake pipe will be connected. If half disk

set is required, install with shoulder of disk against stop

in combustion-air inlet.

Fig. 28—Combustion-Air and Vent Pipe Connections

A96187

COMBUSTION-

AIR

COMBUSTION-

AIR

AIR

FLOW

VENT

VENT

VENT

AIR

FLOW

AIR

FLOW

AIR

FLOW

UPFLOW

DOWNFLOW

HORIZONTAL-LEFT DISCHARGE

HORIZONTAL-RIGHT DISCHARGE

Select 1 vent pipe connection and

1 combustion-air pipe connection.

COMBUSTION-

AIR

COMBUSTION-

AIR

COMBUSTION-

AIR

COMBUSTION-

AIR

VENT

VENT

VENT

NOTE:

Select 1 vent pipe connection and

1 combustion-air pipe connection.

NOTE:

—22—

→