Mount the burner, Maintain electrode specifi cations – Beckett CF1000 User Manual

Page 8

8

Form 6104 BCF10-R06

Mount the burner

Mount fl ange(s) on air tube

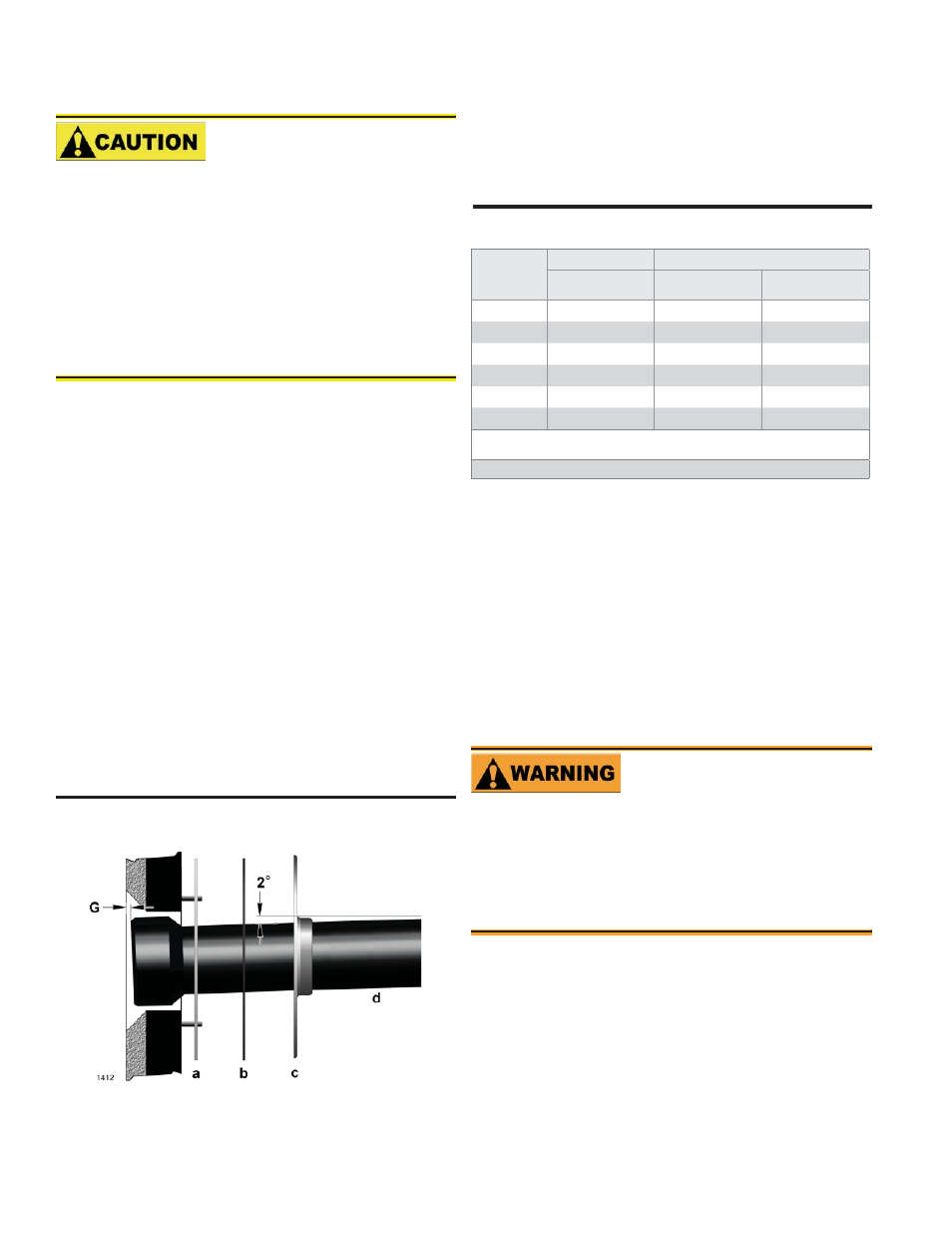

This section does not apply to burners with welded fl ang-

es.

Do not install air tube on burner.

For non-pressure fi ring fl ange, refer to Figure 3: Install

gasket (item a) and fl ange (item c). Ignore the next

paragraph.

For pressure-fi ring fl ange, refer to Figure 3: Slide gasket

(item a) onto the air tube, making sure the top of the air tube

is up. Pre-drill holes in the pressure fi ring plate (item b) to

match the appliance studs. Slide the pressure fi ring plate

(item b) and fl ange (item c) onto the air tube as shown.

Wrap ceramic fi ber rope around the air tube and press

tightly into the inside diameter of the fl ange (item c).

Slide the air tube (item d) into position in the appliance

front. Tighten the fl ange-mounting-stud nuts. Set the

insertion of the air tube so dimension G is 1/4” nominal.

Pitch the air tube at 2° from horizontal as shown and secure

the fl ange to the air tube.

y

y

y

y

y

y

Protect the Air Tube From

Overheating

Overheating could cause damage to the air

tube and other combustion components lead-

ing to equipment malfunction and impaired

combustion performance.

The end of the air tube must not extend into the com-

bustion chamber unprotected unless it has been factory-

tested and specifi ed by the appliance manufacturer.

Position the end of the air tube 1/4” back from fl ush with

the refractory inside entry wall to prevent damage from

overheating.

y

y

Figure 3 - Mount fl ange(s) on air tube

Mount air tube to burner

Remove the rear access door from the back of the burner

for improved access to the interior.

Attach the air tube to the burner with the bolts and acorn

nuts provided. The acorn nuts must go on the outside of the

burner, with the bolts inserted from the inside.

y

y

Install nozzle

See Figure 4. Install the oil nozzle in the nozzle adapter.

Use a 3/4” open-end wrench to steady the nozzle adapter

and a 5/8” open-end wrench to turn the nozzle. Tighten

securely but do not over-tighten.

Check, and adjust if necessary, the critical dimensions P,

Q, R and S shown in the drawing. Verify that the oil tube

assembly and electrodes are in good condition, with no

cracks or damage.

Check electrodes

y

y

Table 2 - Air Tube Capacity vs. Firebox Pressure

Firebox

Pressure

(in. w.c.)

Tube A

Tube B

10% turndown

No reserve air

10% turndown

0.0

2.24

2.45

2.65

0.2

2.52

2.76

2.98

0.4

2.80

3.06

3.31

0.6

3.07

3.37

3.64

0.8

3.35

3.67

3.97

1.0

3.91

4.29

4.63

Note: 10% turndown indicates suffi cient reserve air to reduce the CO

2

in the fl ue to 90% of

its value.

Note: The above ratings may vary 5% due to variations in actual job conditions.

Adjust the electrode gap and position in relation to the

nozzle to the specifi cations shown in Figure 4.

y

Failure to properly maintain these specifi cations

could cause ignition malfunction, puff-back of

hot gases, heavy smoke, asphyxiation, explosion

and fi re hazards.

Maintain Electrode

Specifi cations

Check, and adjust if necessary, the critical dimensions P,

Q, R and S shown in the drawing. Verify that the oil tube

assembly and electrodes are in good condition, with no

cracks or damage.

y