Vent system, Electrical supply, Verify burner components – Beckett CF1000 User Manual

Page 7: Verify fi ring rate, Verify air tube

Form 6104 BCF10-R06

7

The fuel unit nozzle port pressure is factory set at 300 psig.

Some original equipment manufacturer burner applications

may call for a lower pressure to obtain a required fi ring

rate. Do not change this pressure unless directed to do so

by the appliance manufacturer.

Vent system

The fl ue gas venting system must be in good condition and

must comply with all applicable codes.

Electrical supply

Verify that the power connections available are correct for

the burner. All power must be supplied through fused dis-

connect switches.

Verify burner components —

Burner box, Model CF1000

Air tube assembly

Mounting fl ange kit

Pedestal mounting assembly kit (recommended)

Oil nozzle, per Table 1 — Only 45° to 70° solid pattern

nozzles are recommended unless otherwise specifi ed by

appliance manufacturer. (See specifi c appliance recom-

mendation sheet or refer to OEM Spec Guide). Find the

required fi ring rate in the 300 psig column (factory-set fuel

unit pressure). Select the corresponding nozzle from col-

umn 1 (Rated gph @ 100 psig).

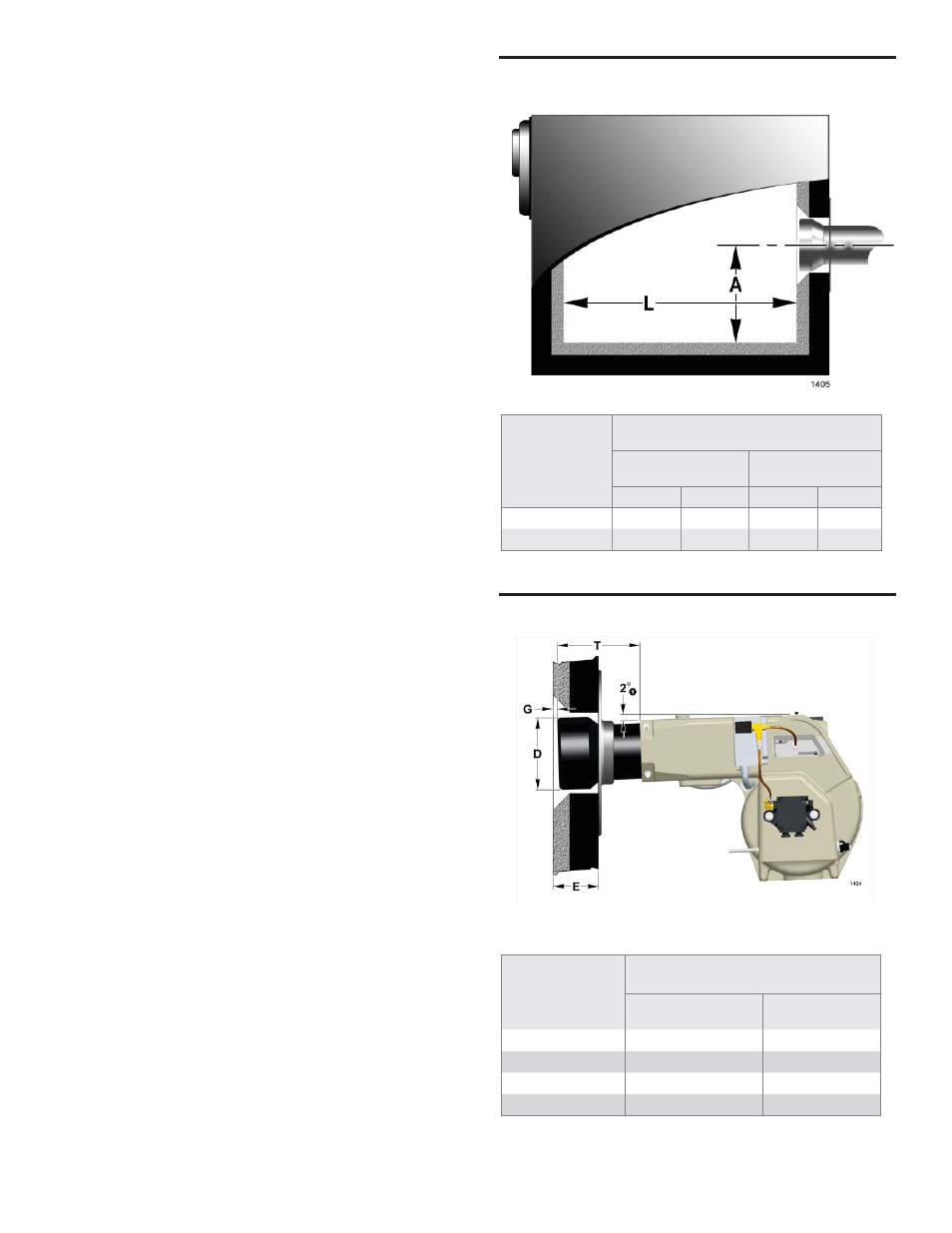

Verify fi ring rate

Refer to appliance manufacturer’s instructions (if available)

for fi ring rate and nozzle selection. Otherwise, the maximum

recommended fi ring rate for the burner depends on the

length of the fi ring chamber and the distance from the

burner center to the chamber fl oor. Verify that the chamber

dimensions are at least as large as the minimum values

given in Figure 1. If the appliance dimensions are smaller

than recommended, reduce the fi ring rate accordingly.

Verify air tube

The information in this section may be disregarded if the

air tube is supplied by the appliance manufacturer.

Two tube arrangements are available –

Tube

A — 4.0 to 10.0 GPH per Table 2

Tube

B — 7.0 to 10.0 GPH per Table 2

Maximum fi ring capacity depends on the fi rebox pressure.

Use Table 2 to verify the correct air tube type for the fi ring

rate required. Use Tube B only when Tube A cannot pro-

vide the fi ring rate required.

See Figure 2 to verify the correct air tube length and air

tube combination code.

y

y

y

y

y

y

y

y

y

y

y

y

y

Firing Rate

Minimum Dimensions

(refractory-lined)

(wet-base boilers)

A

L

A

L

0 to 5 gph

7.0”

25.0”

7.0”

25.0”

5 to 10 gph

8.0”

35.0”

8.0”

40.0”

Install the burner with a 2 deg. pitch as shown

E Insertion depth

G Air tube to inside of chamber

0.25” +/- 0.125

T Air tube length

D Tube diameter

Figure 2 - Air Tube Mounting Dimensions

Figure 1. Min. Combustion Chamber Dimensions

Air Tube Length

(Dimension T)

A.T.C. Codes

(A.T.C. = Air Tube Combination)

Tube A

(Dim. D = 5-1/2”)

Tube B

(Dim. D = 5-3/4”)

0

6.75”

CF66KD

CF66KE

10.25”

CF102KD

CF102KE

13.75”

CF136KD

CF136KE

17.75”

CF176KD

CF176KE