Bryant Durapac Plus Series 551a User Manual

Page 29

—

29

—

If the CONFIG button is pressed and held for more than

30 seconds and released, the EconoMi$er controller will

enable the enthalpy comparison strategy (with outdoor air

enthalpy and return air enthalpy sensors installed).

VIII. POWER FAILURE

Dampers have a spring return. In event of power failure,

dampers will return to fully closed position until power is

restored. Do not manually operate damper motor.

IX. REFRIGERANT CHARGE

Amount of refrigerant charge is listed on unit nameplate and

in Table 1. Refer to Carrier GTAC II; Module 5; Charging,

Recovery, Recycling, and Reclamation section for charging

methods and procedures. Unit panels must be in place when

unit is operating during charging procedure.

NOTE: Do not use recycled refrigerant as it may contain

contaminants.

A. No Charge

Use standard evacuating techniques. After evacuating sys-

tem, weigh in the specified amount of refrigerant (refer to

Table 1).

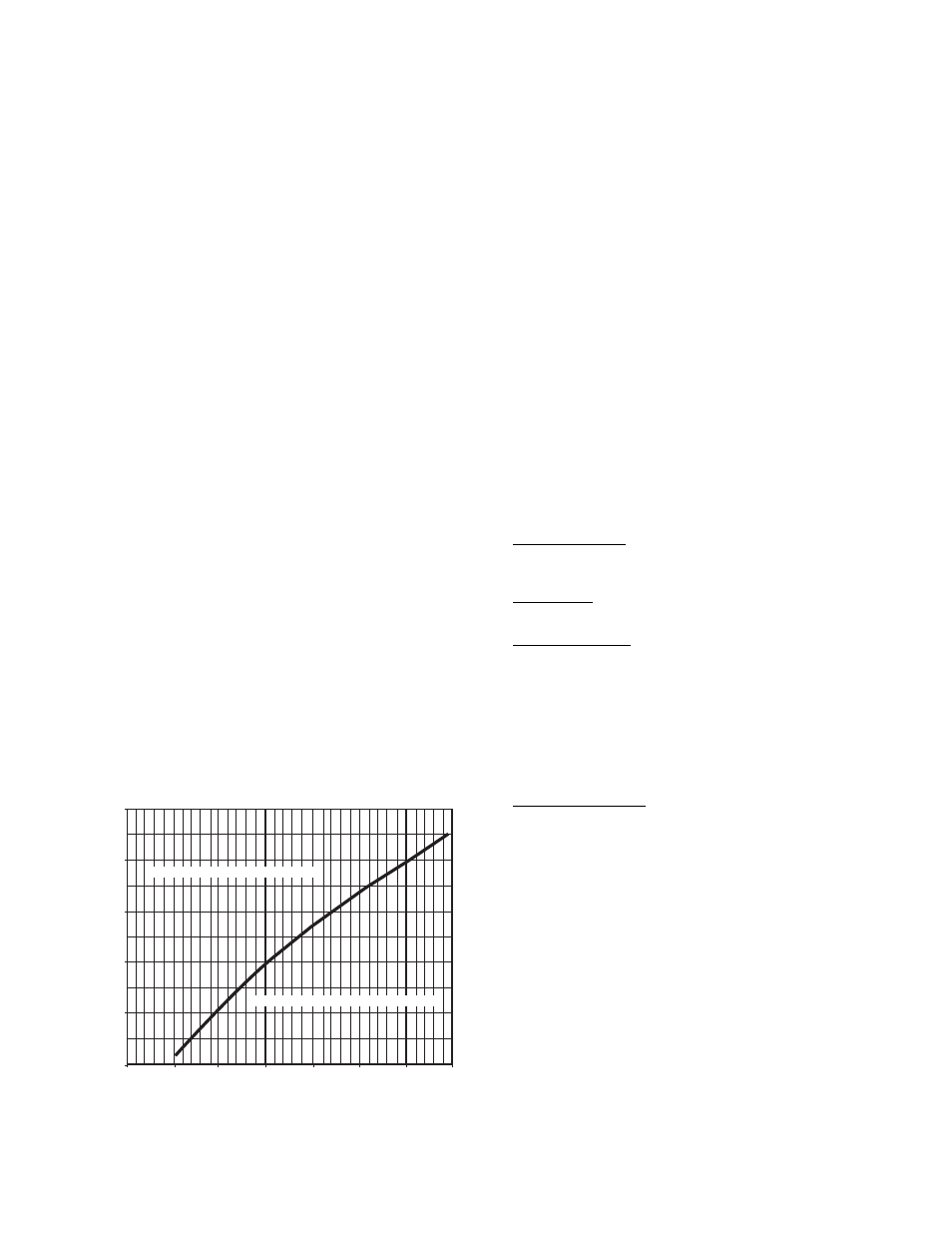

B. Low Charge Cooling

Using cooling charging chart (see Fig. 35), add or remove

refrigerant until conditions of the chart are met. Note that

charging chart is different from those normally used. An

accurate pressure gage and temperature-sensing device is

required. Charging is accomplished by ensuring the proper

amount of liquid subcooling. Measure liquid line pressure at

the liquid line service valve using pressure gage. Connect

temperature sensing device to the liquid line near the liquid

line service valve and insulate it so that outdoor ambient

temperature does not affect reading.

C. To Use The Cooling Charging Chart

Use the above temperature and pressure readings, and find

the intersection point on the cooling charging chart. If inter-

section point on chart is above line, add refrigerant. If inter-

section point on chart is below line, carefully recover some of

the charge. Recheck suction pressure as charge is adjusted.

NOTE: Indoor-air CFM must be within normal operating

range of unit. All outdoor fans must be operating.

The TXV (thermostatic expansion valve) is set to main-

tain between 15 and 20 degrees of superheat at the compres-

sors. The valves are factory set and should not require

re-adjustment.

D. Perfect Humidity™ System Charging

The system charge for units with the Perfect Humidity

option is greater than that of the standard unit alone. The

charge for units with this option is indicated on the unit

nameplate drawing. To charge systems using the Perfect

Humidity Dehumidification package, fully evacuate, recover,

and re-charge the system to the nameplate specified charge

level. To check or adjust refrigerant charge on systems using

the Perfect Humidity Dehumidification package, charge per

the standard subcooling charts. The subcooler MUST be

deenergized to use the charging charts. The charts reference

a liquid pressure (psig) and temperature at a point between

the condenser coil and the subcooler coil. A tap is provided

on the unit to measure liquid pressure entering the sub-

cooler (leaving the condenser).

X. FILTER DRIER

Replace whenever refrigerant system is exposed to

atmosphere.

XI. PROTECTIVE DEVICES

A. Compressor Protection

Overtemperature

Each compressor has an internal protector to protect it

against excessively high discharge gas temperatures.

Overcurrent

Each compressor has internal line break motor protection.

Crankcase Heater

All units are equipped with a 70-watt crankcase heater to

prevent absorption of liquid refrigerant by oil in the crank-

case when the compressor is idle. The crankcase heater is

energized whenever there is a main power to the unit and

the compressor is not energized.

IMPORTANT: After prolonged shutdown or servicing, ener-

gize the crankcase heaters for 24 hours before starting the

compressors.

Compressor Lockout

If any of the safeties (high-pressure, low-pressure, freeze

protection thermostat, compressor internal thermostat) trip,

or if there is loss of power to the compressors, the CLO (com-

pressor lockout) will lock the compressors off. To reset, man-

ually move the thermostat setting.

B. Evaporator Fan Motor Protection

A manual reset, calibrated trip, magnetic circuit breaker

protects against overcurrent. Do not bypass connections or

increase the size of the breaker to correct trouble. Determine

the cause and correct it before resetting the breaker.

C. Condenser-Fan Motor Protection

Each condenser-fan motor is internally protected against

overtemperature.

D. High- and Low-Pressure Switches

If either switch trips, or if the compressor overtemperature

switch activates, that refrigerant circuit will be automati-

cally locked out by the CLO. To reset, manually move the

thermostat setting.

50

40

100

150

200

250

300

350

400

60

80

100

120

140

ALL OUTDOOR FANS MUST BE OPERATING

LIQUID PRESSURE AT LIQUID VALVE (PSIG)

LIQUID

TEMPERA

TURE

A

T

LIQUID V

A

L

VE (DEG F)

BOTH CIRCUITS

REDUCE CHARGE IF BELOW CURVE

ADD CHARGE IF ABOVE CURVE

Fig. 35 — Cooling Charging Chart