Venting, Multiple heater manifold – American Water Heater ABCG3 User Manual

Page 9

9

Where an exhaust fan is supplied in the same room with a

heater, sufficient openings for air must be provided in the

walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE

DRAWN INTO THE ROOM THROUGH THE CHIMNEY,

CAUSING POOR COMBUSTION. SOOTING MAY RESULT IN

SERIOUS DAMAGE TO THE HEATER AND RISK OF FIRE OR

EXPLOSION.

UNCONFINED SPACE

In buildings of conventional frame, brick, or stone construction,

unconfined spaces may provide adequate air for combustion,

ventilation and draft hood dilution.

If the unconfined space is within a building of tight construction

(buildings using the following construction: weather stripping,

heavy insulation, caulking, vapor barrier, etc.), air for combustion,

ventilation and draft hood dilution must be obtained from outdoors.

The installation instructions for confined spaces in tightly

constructed buildings must be followed to ensure adequate air

supply.

CONFINED SPACE

When drawing combustion and dilution air from inside a

conventionally constructed building to a confined space,

such a space shall be provided with two permanent

openings, ONE IN OR WITHIN 12 INCHES (30.5cm) OF

THE ENCLOSURE TOP AND ONE IN OR WITHIN 12 INCHES

(30.5cm) OF THE ENCLOSURE BOTTOM. Each opening

shall have a free area of at least one square inch per 1000

Btuh (2,225mm

2

/Kw) of the total input of all appliances in

the enclosure, but not less than 100 square inches (645

square cm).

If the confined space is within a building of tight construction,

air for combustion, ventilation, and drafthood dilution must be

obtained from outdoors. When directly communicating with

the outdoors or communicating with the outdoors through

vertical ducts, two permanent openings, located in the above

manner, shall be provided. Each opening shall have a free

area of not less than one square inch per 4000 Btuh

(8,900mm

2

/Kw)of the total input of all appliances in the

enclosure. If horizontal ducts are used, each opening shall

have a free area of not less than one square inch per 2000

Btuh (4,450mm

2

/Kw)of the total input of all appliances in the

enclosure.

VENTING

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING MUST

BE FOLLOWED TO AVOID CHOKED COMBUSTION OR

RECIRCULATION OF FLUE GASES. SUCH CONDITIONS

CAUSE SOOTING OR RISKS OF FIRE AND ASPHYXIATION.

Heater must be protected from freezing downdrafts.

Remove all soot or other obstructions from the chimney that will

retard a free draft.

Type B venting is recommended with these heaters. For typical

venting application see TECHNICAL DATA VENTING on pages

10 and 11.

This water heater must be vented in compliance with all local

codes, the current edition of the National Fuel Gas Code (ANSI-

Z223.1) and with the Category I Venting Tables.

If any part of the vent system are exposed to ambient

temperatures below 40°F it must be insulated to prevent

condensation.

• Do not connect the heater to a common vent or chimney with

solid fuel burning equipment. This practice is prohibited by

many local building codes as is the practice of venting gas

fired equipment to the duct work of ventilation systems.

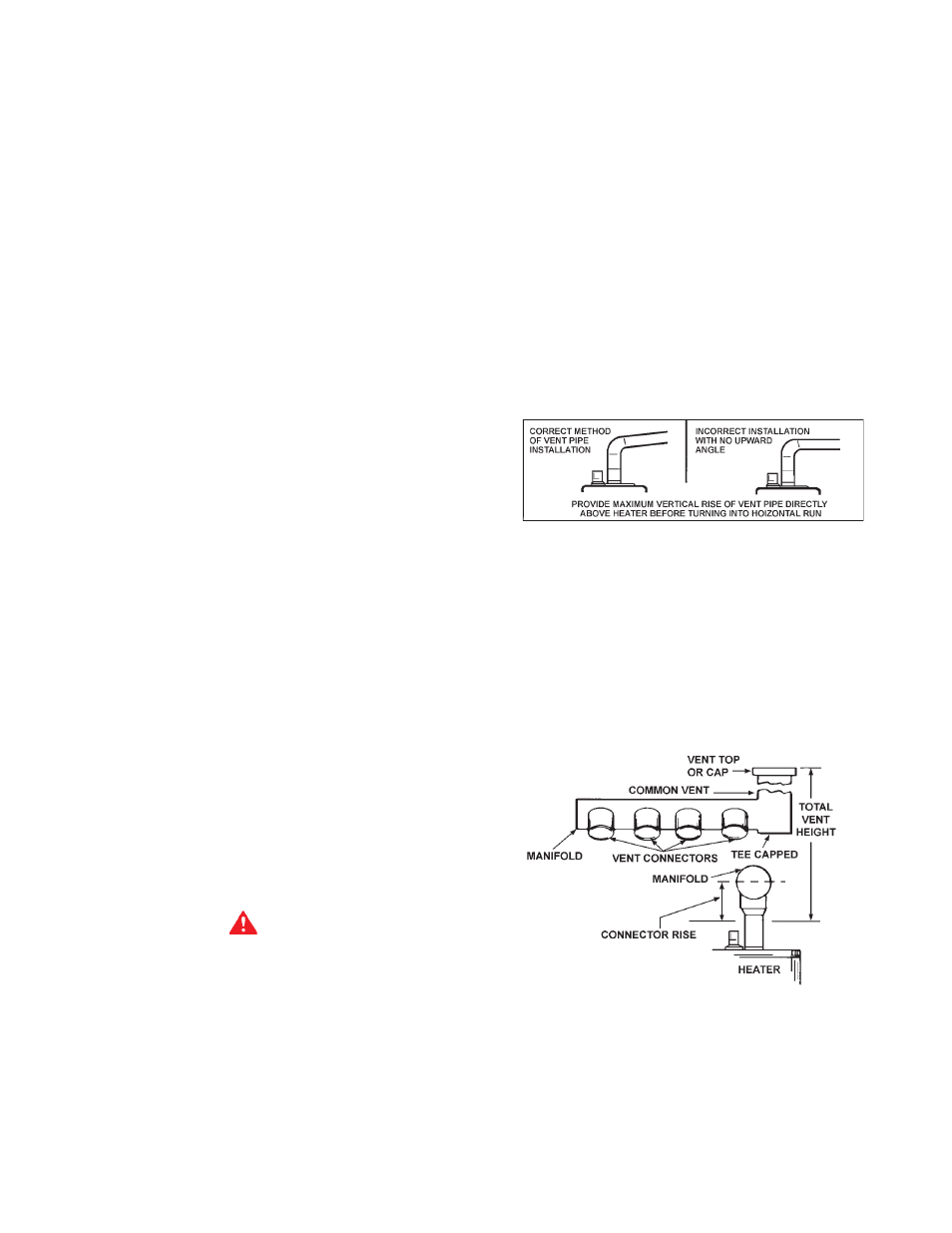

FIGURE 6

• Where a separate vent connection is not available and the

vent pipe from the heater must be connected to a common

vent with an oil burning furnace, the vent pipe should enter

the smaller common vent or chimney at a point above the

large vent pipe.

MULTIPLE HEATER MANIFOLD

Figure 7 and tables on pages 10 and 11 should be used for

horizontally manifolding two or more heaters.

FIGURE 7