The sheffer advantage, Sheffer cylinders are better cylinders, The performance you expect from a quality cylinder – Sheffer A SERIES User Manual

Page 22

Sheffer

Cylinders

are Better

Cylinders

The performance

you expect from a

quality cylinder

©

Longer lifetime of service

©

Minimal downtime

©

Fast and easy installation

©

Simple, affordable repairs

©

No special tool required

to make repairs

©

Lower operating cost

©

More options available

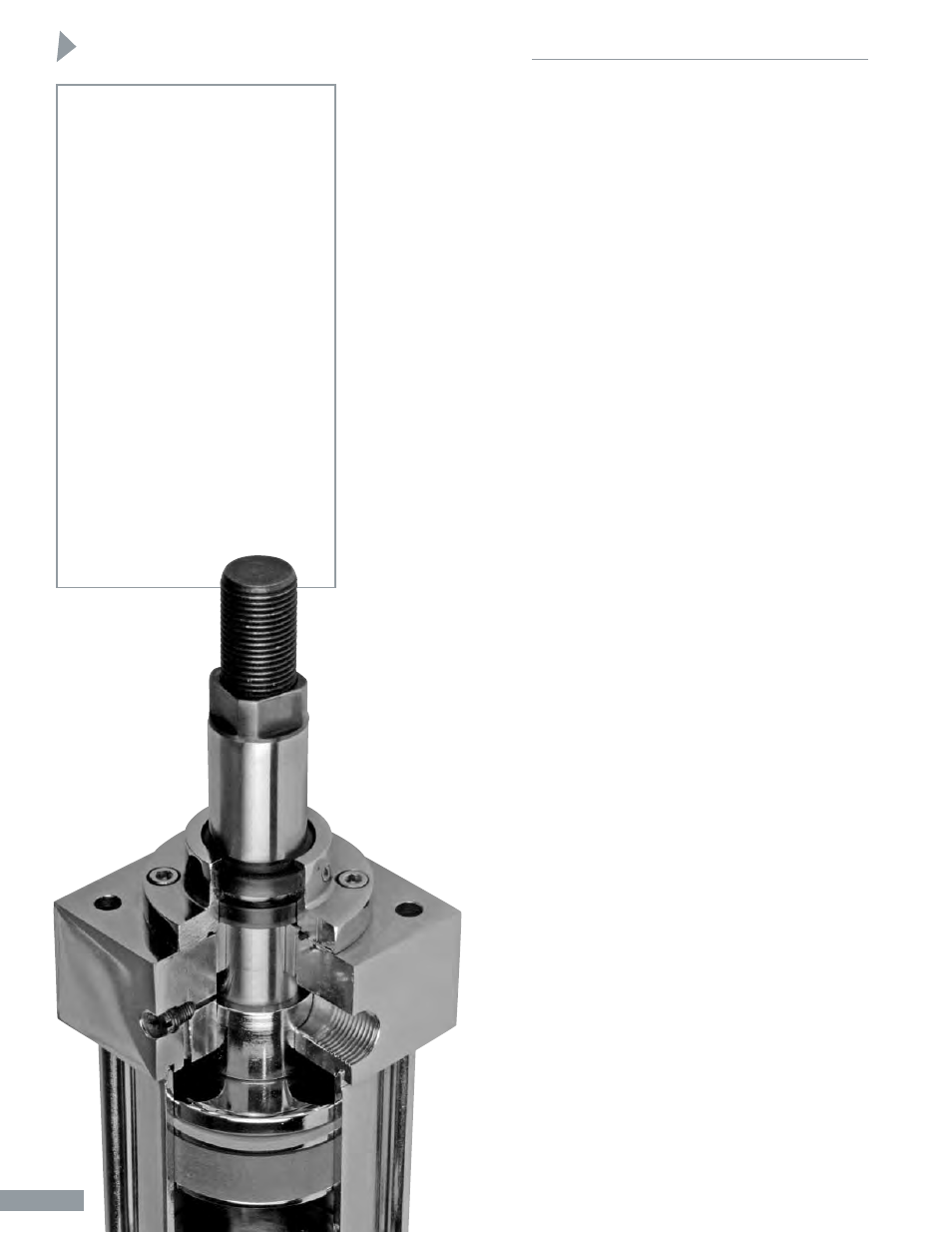

Studded Rod End

(Standard, except on C20 Series)

Sheffer’s rod end design virtually

eliminates rod end breakage! The

rod ends of many competitive cylin-

ders are cut from the piston rod, cre-

ating a weak point at the threads.

Our studded connection routes

stress factors away from this weak

point, so rod-end failure is nearly

impossible. Also, rod ends can be

replaced without changing the entire

piston rod, thereby reducing down-

time and repair costs.

Four Full Wrench Flats

(Standard on all Sheffer cylinders)

For convenience, time and money

savings during cylinder installation

or replacement, Sheffer cylinders are

produced with four full wrench flats.

With our design, a flat is always posi-

tioned for a good wrench hold with

normal tools. Our cylinders come

this way because unconventional

tools and methods are often used

when a wrench flat isn’t convenient

— possibly marring the rod surface

which can damage seals and cause

leaks.

Removable Rod Gland

(Not available on select small bore cylinders)

The wiper and pressure seals on

Sheffer cylinders are encapsulated

behind a removable rod gland that is

bolted to the front of the cylinder.

“On line” changing of seals is fast

and easy using normal tools,

without disturbing torque

settings, removing the

rod bearing or tear-

ing down the

cylinder. This fea-

ture dramatically

increases

productivity by

reducing downtime

and repair costs.

Separate Rod Bearing

(Standard on most Sheffer cylinders)

On Sheffer cylinders, the rod bearing is

a hydrodynamic “flooded bearing”,

which greatly reduces wear and

extends part life. It’s also inboard

from the seals and a separate compo-

nent, so if changeout is needed, the

seals need not be replaced — and

vice versa. No special tools are

required. Moreover, the rod bearing

can be removed and replaced without

having to loosen tie rods or tear down

the cylinder. That saves downtime,

plus the cost of parts and labor.

Chamfered Tube Ends

(Standard on most Sheffer cylinders)

A small angle, or chamfer, is

machined into the end of each

Sheffer piston tube for quick, easy

and reliable repairs. If the piston

and rod have been removed (to

replace seals for example), when the

piston is pushed back in, the chamfer

physically compresses the seal into

the piston like a built-in funnel.

Special compression tools aren’t

needed during assembly and chances

of seal damage are minimized. The

chamfer design also prohibits extru-

sion of the O-ring once the tie rods

are tightened. This forms a superior

seal and diminishes the chance of

leakage at the head and cap joint.

Slipper Piston Seal

& Bearing

(Standard on all hydraulic cylinders)

The slipper piston seal and bearing

on Sheffer cylinders are a standard

option, not a cost-additive feature

other manufacturers offer when their

designs are inadequate. Our

Teflon

®

-based surfaces are an excel-

lent lubricant, demonstrating a very

low coefficient of friction with low

heat. As the cylinder moves back

and forth, the Teflon also migrates

into the pores of the cylinder tube,

creating an even better lubricating

surface. Slipper seals and bearings

— another reason Sheffer cylinders

reduce costs and downtime while

increasing productivity.

The Sheffer Advantage

Our Cylinders are Designed

with the End User in Mind

A-21