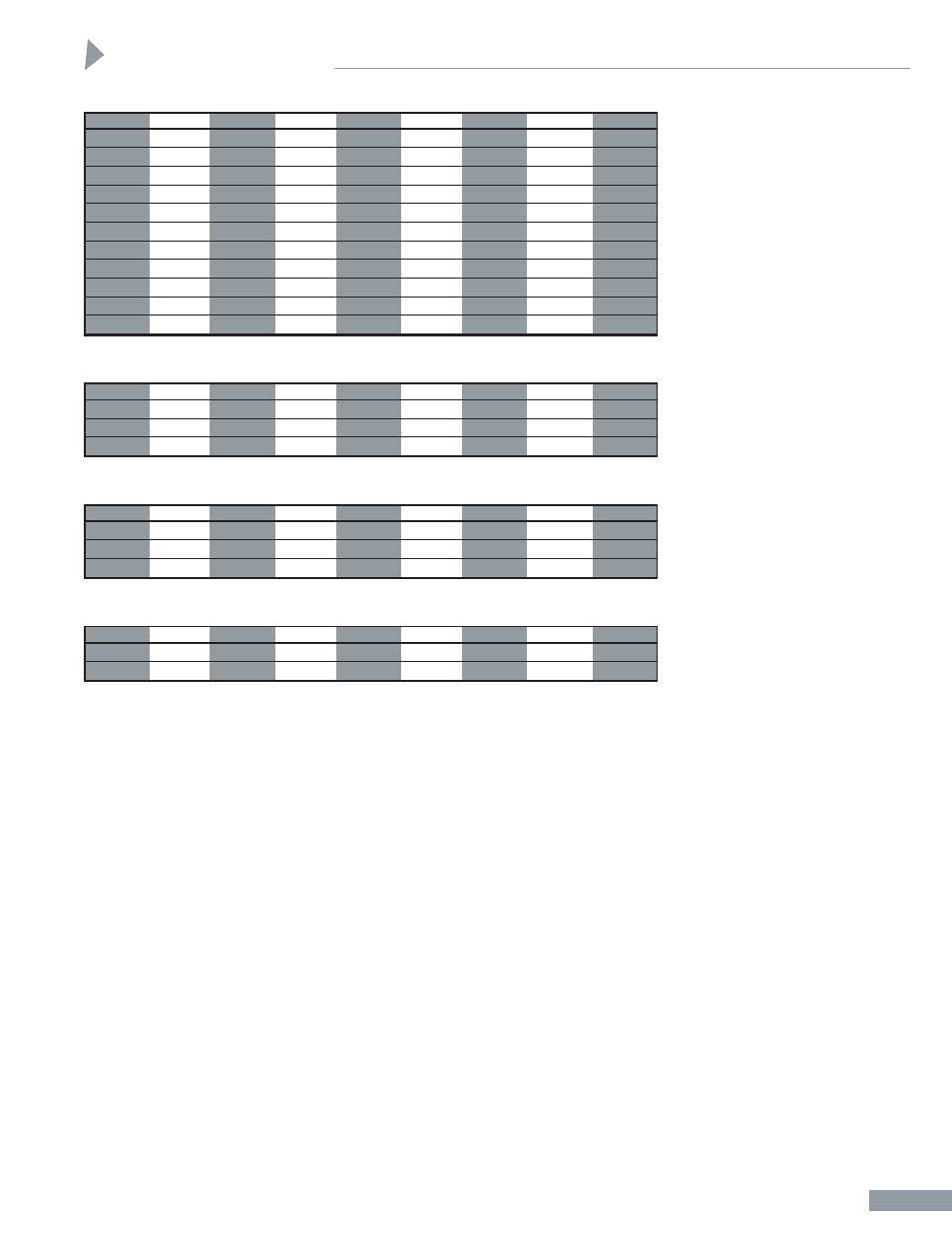

Dimensions, A-12, Clevis and trunnion mounting cylinder dimensions – Sheffer A SERIES User Manual

Page 13: These dimensions** affected by rod size, These dimensions** affected by rod size and stroke, These dimensions affected by stroke

Mounting Information

Rectangular Type Flanges are

sufficient for normal cylinder

applications. For long stroke

cylinders (over 36

"

), large rod

diameters, or where extra rigidity

is required, square type flanges

are recommended. See the

Engineering Brochure for Long

Stroke information and detailed

Mounting Data.

Pilot Diameters (B in table Page

A-17) are accurately machined

for aligning cylinders to the

work. On installations where the

pilot diameter cannot be used for

aligning cylinder to work, we

recommend drilling and dowel

pinning flanges after cylinder is

tightened in place to prevent

shifting.

FLANGES SHOULD BE SOLIDLY

MOUNTED to a rigid section of

the machine with high tensile

bolts (socket head type

recommended).

1

1

/

8

" THRU 6" BORES

Dimensions

Clevis and Trunnion Mounting Cylinder Dimensions

A-12

BORE

1

1

/

8

1

1

/

2

2

2

1

/

2

3

1

/

4

4

5

6

E

1

3

/

4

2

2

1

/

2

3

3

3

/

4

4

1

/

2

5

1

/

2

6

1

/

2

EE NPTF

1

/

4

3

/

8

3

/

8

3

/

8

1

/

2

1

/

2

1

/

2

3

/

4

F

3

/

8

3

/

8

3

/

8

3

/

8

5

/

8

5

/

8

5

/

8

3

/

4

FB*

1

/

4

1

/

4

5

/

16

5

/

16

3

/

8

3

/

8

1

/

2

1

/

2

G

1

3

/

32

1

15

/

32

1

3

/

8

1

3

/

8

1

5

/

8

1

5

/

8

1

5

/

8

1

7

/

8

J

27

/

32

31

/

32

7

/

8

7

/

8

1

1

/

8

1

1

/

8

1

1

/

8

1

3

/

8

K

7

/

32

7

/

32

1

/

4

1

/

4

5

/

16

5

/

16

7

/

16

7

/

16

MM

1

/

2

5

/

8

5

/

8

5

/

8

1

1

1

1

3

/

8

R

1.19

1.43

1.84

2.19

2.76

3.32

4.10

4.88

TF

2

3

/

8

2

3

/

4

3

3

/

8

3

7

/

8

4

11

/

16

5

7

/

16

6

5

/

8

7

5

/

8

UF

3

3

3

/

8

4

1

/

8

4

5

/

8

5

1

/

2

6

1

/

4

7

5

/

8

8

5

/

8

These Dimensions** Affected By Rod Size

BORE

1

1

/

8

1

1

/

2

2

2

1

/

2

3

1

/

4

4

5

6

W

5

/

8

5

/

8

5

/

8

5

/

8

3

/

4

3

/

4

3

/

4

7

/

8

WF

1

1

1

1

1

3

/

8

1

3

/

8

1

3

/

8

1

5

/

8

Y

1

22

/

32

1

15

/

16

1

15

/

16

1

15

/

16

2

7

/

16

2

7

/

16

2

7

/

16

2

13

/

16

These Dimensions** Affected By Rod Size and Stroke

BORE

1

1

/

8

1

1

/

2

2

2

1

/

2

3

1

/

4

4

5

6

XF

4

3

/

8

4

5

/

8

4

5

/

8

4

3

/

4

5

5

/

8

5

5

/

8

5

7

/

8

6

5

/

8

ZB

4

19

/

32

4

27

/

32

4

7

/

8

5

5

15

/

16

5

15

/

16

6

5

/

16

7

1

/

16

ZF

4

3

/

4

5

5

5

1

/

8

6

1

/

4

6

1

/

4

6

1

/

2

7

3

/

8

These Dimensions Affected By Stroke

BORE

1

1

/

8

1

1

/

2

2

2

1

/

2

3

1

/

4

4

5

6

LB

3

3

/

4

4

4

4

1

/

8

4

7

/

8

4

7

/

8

5

1

/

8

5

3

/

4

P

2

3

/

16

2

1

/

4

2

1

/

4

2

3

/

8

2

5

/

8

2

5

/

8

2

7

/

8

3

1

/

8

For rod end information see Pages A-17 and A-18

*Clearance hole for indicated bolt size.

**Dimensions shown are for standard rod size only. For oversize and 2:1 rods, add N dimension

shown on rod end chart, Page A-17.