Howard Substation Transformers User Manual

Page 7

Copyright © 2013 Howard Industries, Inc.

Howard Industries, Inc.

Laurel, MS 39440

www.howardtransformers.com

Document No. 2.4.18

Revision: 2

Issued: October, 2013

7

Medium Power Substation Transformers

34-10

class) (Figure 13).

Sealed motor-driven fans are

mounted on radiators to provide

increased air flow. Fan operation

may be manual or may be controlled

automatically by temperature sensors

mounted inside the transformer. Fans

are connected to a weatherproof

control box with weatherproof cable

and a separable connector.

A second stage of forced-air cooling

may be used (ONAF/ONAF class) to

provide a further increase in load

capacity beyond that provided by

single-stage forced-air cooling.

Stages one and two are operated

automatically by heat sensors

mounted inside the transformer tank

and a control panel mounted inside

the control cabinet.

FLUID PRESERVATION

A sealed-tank fluid preservation

system is standard on all Howard

medium power transformers. The

interior of the tank is sealed from the

ambient atmosphere, such that the

gas-plus-oil volume remains constant

throughout the range of normal

operating temperatures. An automatic

pressure relief device is provided to

vent excessive pressure that might

build up gradually during extreme

overloads or fault conditions. A

pressure/vacuum gauge is provided

to measure internal pressure. Prior to

shipping the gas space is pressurized

with a dry air or nitrogen blanket.

INERT GAS SYSTEM

An optional nitrogen inert-gas system

provides a constant nitrogen

atmosphere in the gas space of the

transformer (Figure 14). The

nitrogen blanket protects the

transformer fluid from deterioration

that could occur from exposure to

moisture or oxygen. Main system

components include a nitrogen

cylinder, pressure regulators, valves,

and gauges. The system also includes

provisions for various pressure

alarms. A lockable weatherproof

enclosure protects the system.

BUSHINGS

Standard bushings are oil-filled

condenser-type with porcelain

housings (Figure 15).

All bushings meet the requirements

of the IEEE C57.19 series of

standards.

CURRENT TRANSFORMERS

Current transformers (CTs) are

bushing-mounted in the main tank

interior (Figure 16). All CTs meet

the requirements of the IEEE C57.13

series of standards.

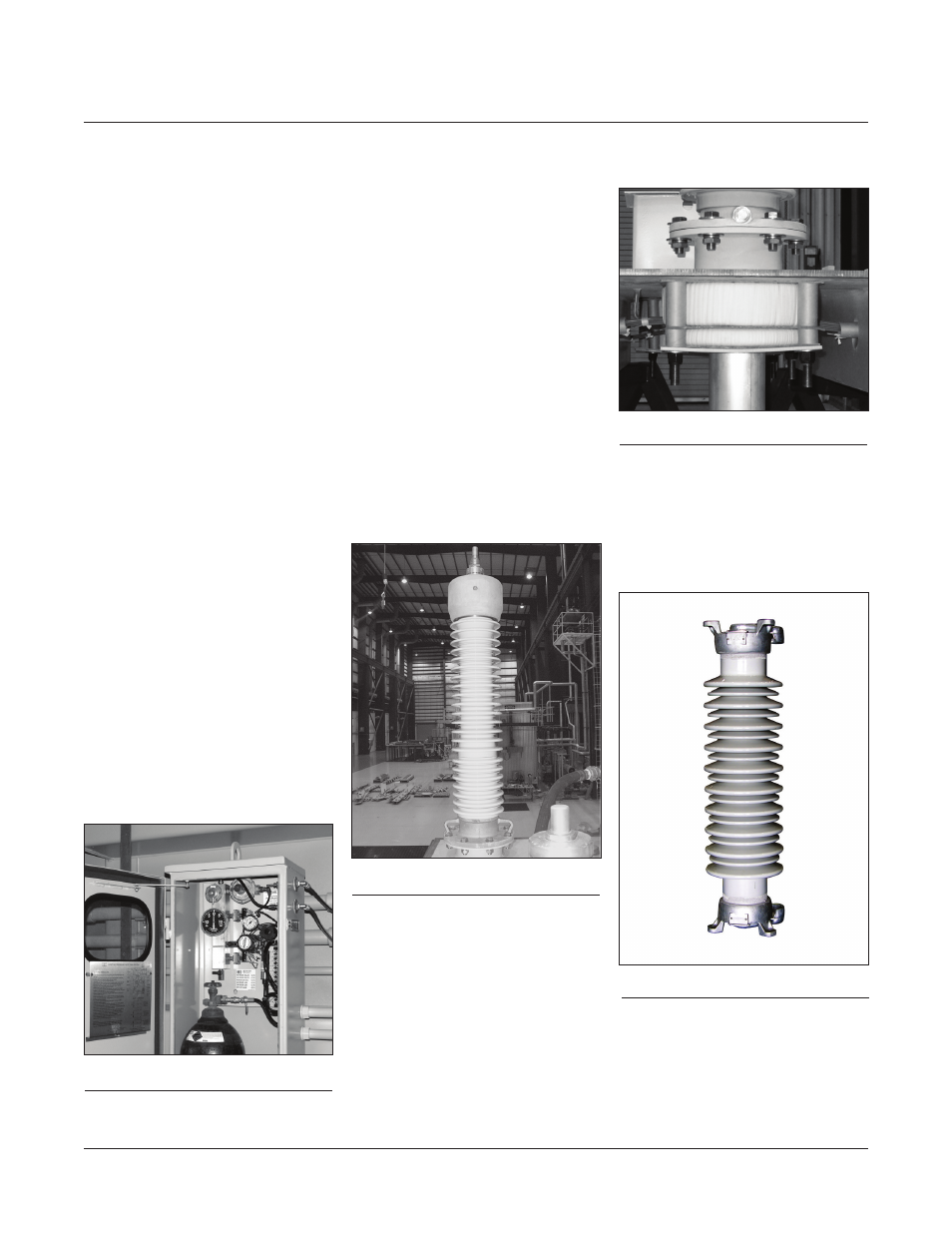

SURGE ARRESTERS

Surge arresters are porcelain or

polymer housed, gapless metal-

oxide-varister (MOV) type (Figure

17), externally mounted on heavy

steel brackets. All arresters meet the

requirements of IEEE C62.11.

Figure 14:

Nitrogen system

Figure 15:

High voltage bushing

Figure 16:

CTs mounted under cover

Figure 17:

Lightning arrester