Introduction, Initial checkout, Installation – Young Gill Propeller Anemometer Models 27106DT User Manual

Page 2: Calibration, Gill propeller anemometer

Page 1

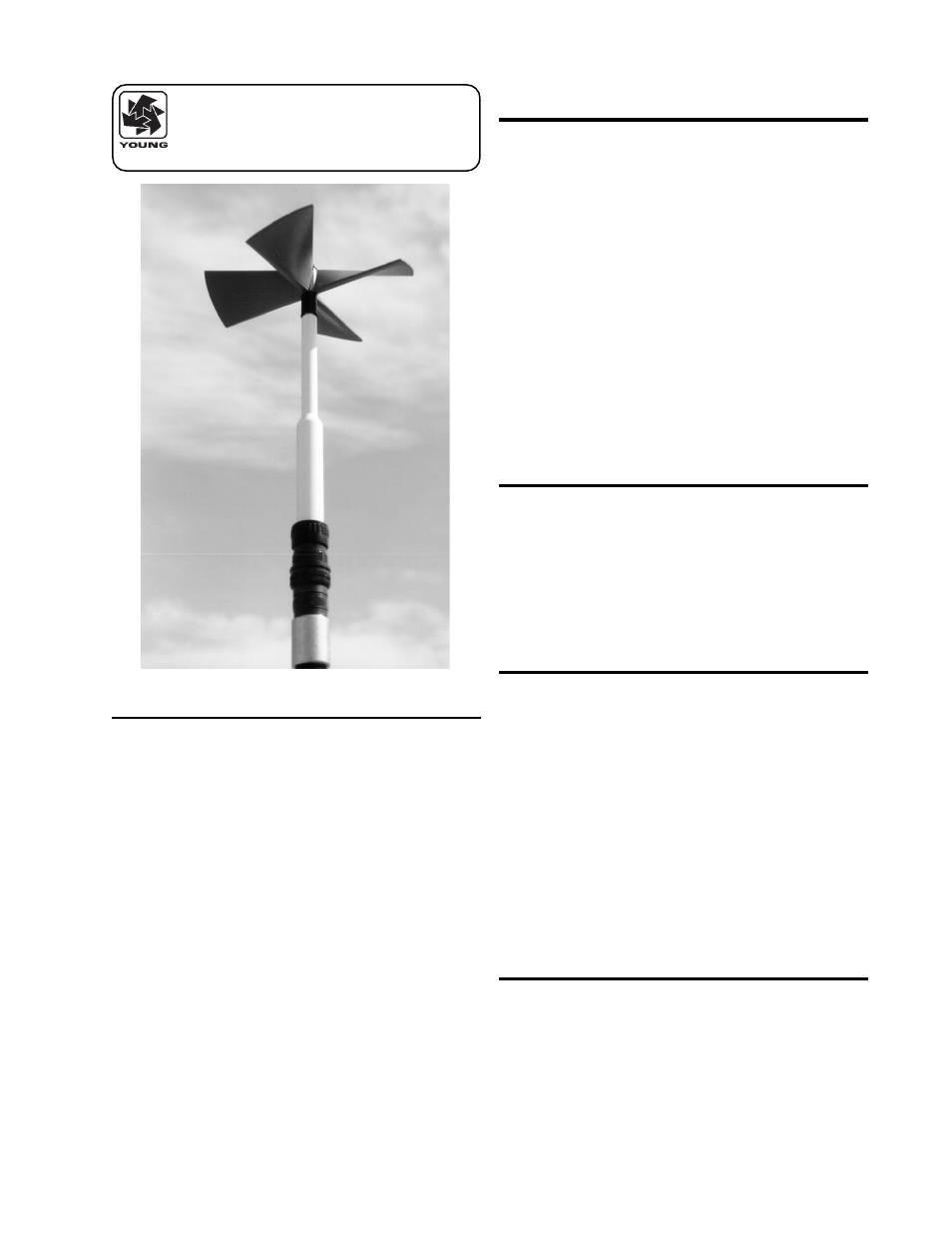

INTRODUCTION

The Gill Propeller Anemometer Photochopper is a low threshold

precision air velocity sensor employing a fast response helicoid

propeller. The instrument uses a high quality optical photo chopper

which converts propeller rotation to a square wave signal whose

frequency is linearly proportional to air velocity. The output signal is

the same regardless of propeller rotation. For applications where

propeller rotation in two directions is required, the model 27106F is

offered.

Airflow from any direction may be measured, however, the

propeller responds only to the component of the air flow which is

parallel to the axis of its rotation. Off-axis response closely

approximates a cosine curve (see accompanying graphs) with

appropriate polarity. With perpendicular air flow the propeller does

not rotate.

The instrument mounts to 3/4 inch standard pipe. A rugged cable

connector provides both electrical and mechanical connection. A

dust cap is provided to protect the connector when the instrument

is removed.

INITIAL CHECKOUT

When the instrument is unpacked it should be carefully checked for

any signs of shipping damage. The propeller shaft should rotate

easily without friction.

Using the WIRING DIAGRAM as a guide, connect the instrument to

an oscilloscope or frequency meter and check for proper signals

from the sensor. The calibration may be checked using the methods

outlined in the CALIBRATION section of this manual.

INSTALLATION

Generally, the instrument should be oriented with the propeller

facing the predominant flow of air being measured. In some cases

it is appropriate to orient the instrument so the predominant air flow

is perpendicular to the propeller such as in applications measuring

the vertical component of wind. Keep in mind that off-axis

response increases the effective threshold and distance constant.

For vertical measurements mount the instrument so the propeller

faces upward. This helps prevent moisture or dirt from entering

around the propeller hub and potentially contaminating the

bearings.

If the instrument is used to measure high air velocity or left for

extended periods without attention, tape the threaded cable

connector collar to eliminate the possibility of loosening from

vibration. The threaded joint between the photochopper and shaft

housings may also be taped.

CALIBRATION

Calibration is determined by propeller pitch and the output

frequency of the photo chopper transducer.

The Model 08254 Carbon Fiber Thermoplastic Propeller has a 30

cm/rev pitch. This is equivalent to 0.00500 m/s per rpm and is

accurate to ±1%. Zero offset is insignificant. Formulas for other

units of measurement appear below.

Information on checking bearing and transducer torque, which can

affect propeller threshold, also appear in the MAINTENANCE

section.

SPECIFICATION SUMMARY

Range:

0 to 35 m/s (80 mph)

Sensor:

20 cm diameter 4-blade helicoid

propeller molded of carbon fiber

thermoplastic

Pitch:

30.0 cm air passage per revolution

Distance Constant:

2.1 m (6.9 ft.) for 63% recovery

Threshold Sensitivity:

0.4 m/s (0.8 mph)

Transducer:

Optical photochopper

Power Requirement:

10-14 VDC (12mA @ 12 VDC)

Operating Temp:

-50 to 50°C (-58 to 122°F)

Transducer Output:

Square wave signal with pulse

amplitude approximately equal to

supply voltage -2.

Output Frequency:

10 pulses per propeller revolution

(0.030 m/s per Hz)

MODEL 27106DT

GILL PROPELLER

ANEMOMETER