Wind monitor-se-ma introduction, Initial checkout, Initial setup – Young Serial Output Wind Monitor Model 09106 User Manual

Page 2

Page 1

09106-90(E)

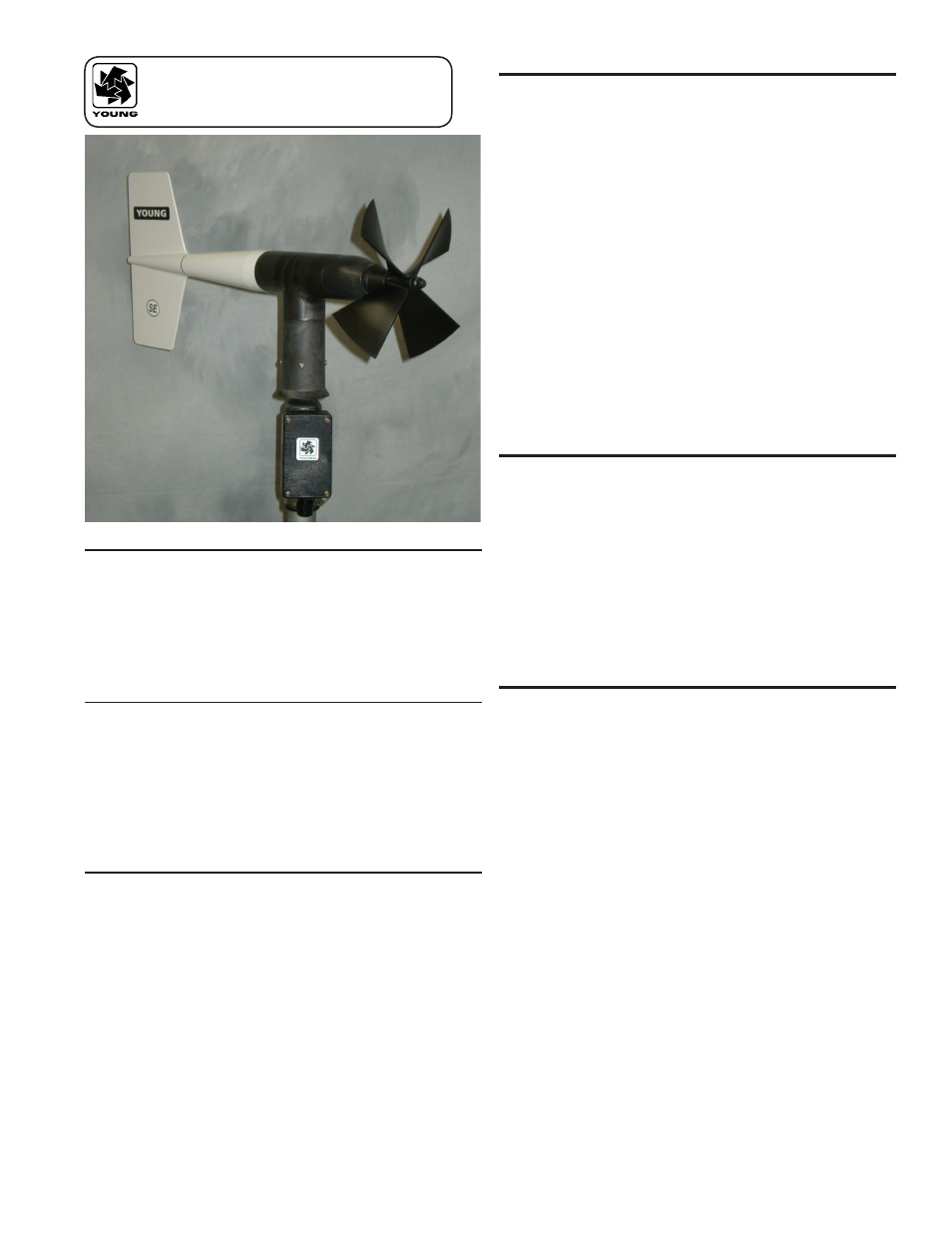

MODEL 09106

WIND MONITOR-SE-MA

INTRODUCTION

The Wind Monitor-SE-MA combines the performance and durability

of the standard Wind Monitor with an optically encoded direction

transducer and serial data output capability.

The wind speed sensor is a four blade helicoid propeller that turns a

multipole magnet. Propeller rotation induces a variable frequency signal

in a stationary coil. Slip rings and brushes are not used.

The wind direction sensor is a durable molded vane. An optical encoder

measures vane angle, thereby eliminating the characteristic deadband

and wear of potentiometer transducers. The encoder is an absolute type

so direction output remains accurate even if power is interrupted.

Raw transducer signals are processed by onboard electronics. A variety

of serial protocols or a conventional calibrated voltage output may be

selected with simple internal jumpers.

The Wind Monitor-SE-MA is designed for superior environmental

resistance. Housing parts are UV stabilized thermoplastic. Fittings are

stainless steel and anodized aluminum. Precision grade stainless steel

ball bearings are used throughout. The instrument mounts on standard

1 inch pipe.

INITIAL CHECKOUT

Remove the sensor from its shipping carton. Remove the plastic nut

from the propeller shaft and install the propeller with the teeth on the

propeller hub engaging the slots on the shaft hub. Tighten plastic

propeller nut

finger-tight only. Do not overtighten.

The instrument is fully balanced, aligned, and calibrated before

shipment. Some simple checks can be made to verify proper function.

Both vane and propeller should rotate easily without friction. Check

vane balance by holding sensor with vane surface horizontal. The vane

should have no tendency to rotate. A slight imbalance will not degrade

performance.

INITIAL SETUP

The 09106 has been calibrated at the factory and requires no additional

adjustments. Operation is configured by onboard jumpers and software

commands.

Unless otherwise specified, the sensor is supplied with the following

settings:

Continuous Serial Output

RMY Protocol

9600 Baud

Meters per Second

Other settings are easily selected by changing the jumper pattern.

Refer to the wiring diagram for jumper J1 and J3 locations.

The

following table lists available features and position of each jumper.

Important Note:

Jumper settings are read at power-up only. If jumpers are changed,

remove and reapply power for the new settings to be used.

At first power-up the Wind Monitor-SE has a 3 second delay before

outputting the first wind speed value.

WIND SPEED SPECIFICATION SUMMARY

Range

0 to 100 m/s (224 mph)

Resolution:

0.1 unit

Accuracy:

±0.3 m/s (0.6 mph) or 1% of reading

Threshold:

1.0 m/s (2.2 mph)

Distance constant:

2.7 m (8.9 ft)

Transducer:

Rotating magnet and stationary coil.

WIND DIRECTION (AZIMUTH) SPECIFICATION SUMMARY

Range:

0-360 degrees

Accuracy:

± 2 degrees

Resolution:

1 degree

Threshold:

1.1 m/s (2.5 mph) @ 10° displacement

Delay distance:

1.3 m (4.3 ft)

Damping ratio:

0.3

Transducer:

Absolute encoder

GENERAL

Power requirement:

11-24 VDC, 20 mA

Dimensions:

Overall height 37 cm

Overall length 55 cm

Propeller 18 cm diameter

Mounting 34 mm (1.34 in) diameter

(standard 1 inch pipe)

Weight:

Sensor weight 1.0 kg (2.2 lb)

Shipping weight 2.3 kg (5.0 lb)

Voltage Output:

WS:

0-5 VDC for 0-100 m/s

WD:

0-5 VDC for 0-540°

Serial RS-485:

2 wire-half duplex, 1200-9600 Baud

RMY, NCAR, NMEA, or RMYT protocols

Polled or continuous

Operating Temperature: -50 to 50°C (-58 to 122°F)