Introduction, Initial check-out, Installation – Young Wind Monitor Model 05103V User Manual

Page 2

Page 1

05103V-90(H)

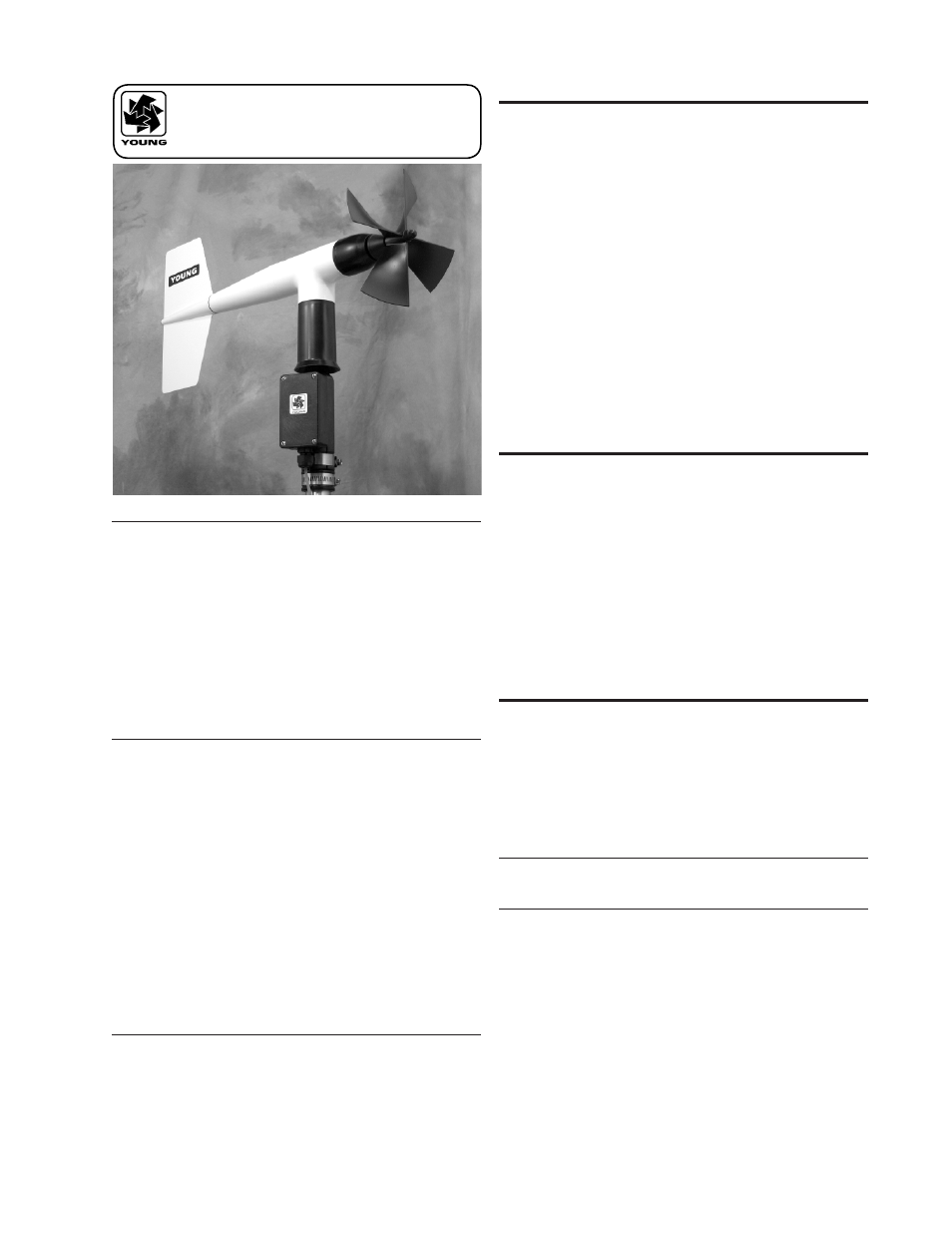

MODEL 05103V

WIND MONITOR

with VOLTAGE OUTPUTS

INTRODUCTION

The Wind Monitor measures horizontal wind speed and direction.

It is rugged and corrosion resistant, yet accurate and lightweight.

The housing, nose cone, propeller, and other components are

injection molded U.V. stabilized plastic. Both the propeller and

vertical shafts use stainless steel precision grade ball bearings.

Propeller rotation produces an AC sine wave signal with frequency

proportional to wind speed. Internal circuitry converts the raw

signal to a linear voltage output.

Vane position is sensed by a 10K ohm precision conductive plastic

potentiometer. This signal is also converted to voltage output.

The instrument mounts directly on standard one inch pipe, outside

diameter 34 mm (1.34"). An orientation ring is provided so the

instrument can be removed for maintenance and re-installed

without loss of wind direction reference. Both the sensor and the

orientation ring are secured to the mounting pipe by stainless steel

band clamps. Electrical connections are made in a junction box at

the base.

INITIAL CHECK-OUT

When the Wind Monitor is unpacked it should be checked carefully

for any signs of shipping damage.

Remove the plastic nut on the propeller shaft. Install the propeller

on the shaft with the serial number of the propeller facing forward

(into the wind). The instrument is aligned, balanced and fully

calibrated before shipment; however, it should be checked both

mechanically and electrically before installation. The vane and

propeller should easily rotate 360° without friction. Check vane

balance by holding the instrument base so the vane surface

is horizontal. It should have near neutral torque without any

particular tendency to rotate. A slight imbalance will not degrade

performance.

INSTALLATION

Proper placement of the instrument is very important. Eddies from

trees, buildings, or other structures can greatly influence wind

speed and wind direction observations. To get meaningful data for

most applications, locate the instrument well above or upwind from

obstructions. As a general rule, the air flow around a structure is

disturbed to twice the height of the structure upwind, six times the

height downwind, and up to twice the height of the structure above

ground. For some applications it may not be practical or necessary

to meet these requirements.

FAILURE TO PROPERLY GROUND THE WIND MONITOR

MAY RESULT IN ERRONEOUS SIGNALS

OR TRANSDUCER DAMAGE.

Grounding the Wind Monitor is vitally important. Without proper

grounding, static electrical charge can build up during certain

atmospheric conditions and discharge through the transducers.

This discharge may cause erroneous signals or transducer failure.

To direct the discharge away from the transducers, the mounting

post assembly in which the transducers are mounted is made with

a special anti-static plastic. It is important that the mounting post

be connected to a good earth ground. There are two ways this

may be accomplished. First, the Wind Monitor may be mounted

on a metal pipe which is connected to earth ground. The mounting

pipe should not be painted where the Wind Monitor is mounted.

Towers or masts set in concrete should be connected to one or

more grounding rods. If it is difficult to ground the mounting post

in this manner, the following method should be used. Inside

the junction box the terminal labeled EARTH GND is internally

WIND SPEED SPECIFICATION SUMMARY

Range

0 to 100 m/s (224 mph)

Sensor

18 cm diameter 4-blade helicoid

polypropylene propeller, 29.4 cm air

passage per revolution

Distance Constant

2.7 m (8.9 ft.) for 63% recovery

Threshold Sensitivity 1.0 m/s (2.2 mph)

Transducer

Centrally mounted stationary coil,

2K Ohm nominal DC resistance

Output Signal

50 mV per M/S

WIND DIRECTION (AZIMUTH) SPECIFICATION SUMMARY

Range

360° mechanical, 355° electrical (5° open)

Sensor

Balanced vane, 38 cm (15 in) turning

radius.

Damping Ratio

0.3

Delay Distance

1.3 m (4.3 ft) for 50% recovery

Threshold Sensitivity 1.1 m/s (2.4 mph) at 10° displacement

Damped Natural

Wavelength

7.4 m (24.3 ft)

Undamped Natural

Wavelength

7.2 m (23.6 ft)

Transducer

Precision conductive plastic potentiometer,

10K ohm resistance (±20%),

0.25% linearity, life expectancy 50 million

revolutions, rated 1 watt at 40°C,

0 watts at 125°C

Output Signal

13.9 mV per degree

GENERAL

Power Requirement:

8 - 24 VDC (5mA @ 12 VDC)

Operating Temperature:

-50 to 50°C (-58 to 122°F)