Commissioning, operation – WIKA 700.02 User Manual

Page 11

WIKA operating instructions differential pressure gauge with piston per ATEX

11

11025859.03 10/2013 GB/D/F/E

GB

7. Commissioning, operation

Hexagon bolt

M8 x 50

Slotted screw M4 x 10

Δp

Differential pressure

stat. pressure max. 250 bar

Overpressure limit ±250 bar

1581007x.02

If the line to the gauge is not rigid enough for a vibration-free installation, the gauge

should be mounted by means of appropriate fastening elements for wall mounting,

or, if necessary, with a capillary.

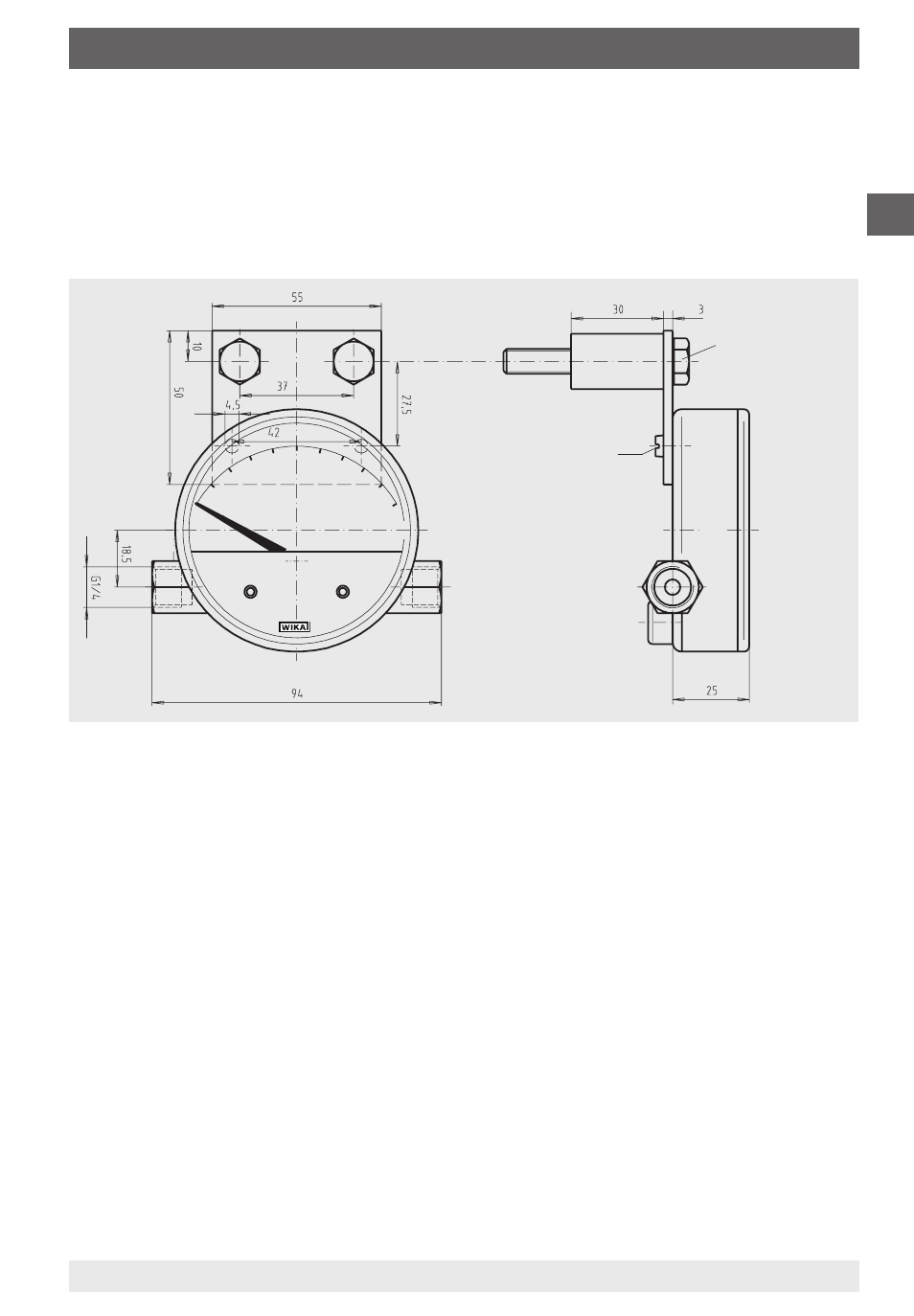

Wall mounting (see drawing)

Installation/fastening by means of mounting bracket

Zero point check

In general, the zero point should only be checked and adjusted after the system

has been depressurised. The system fastening lug on the back of the case can be

easily slackened off for zero point correction of the pressure gauge. Now the zero

point can be readjusted by moving the measuring system to the right or left. After

this has been done the measuring system is to be secured again with the mounting

screw (recommended tightening torque of the mounting screw 1.3 Nm).