Instruction manual ni-205, Weatherproof explosionproof – WIKA APA10 User Manual

Page 6

INSTRUCTION MANUAL

NI-205

Rev. 1 12/02

ETTORE CELLA SPA Viale de Gasperi, 48 - Casella Postale (P.O. Box) 96 - I 20010 Bareggio (MILANO) ITALY

Telefoni +39 029036.1146/7 - 029036.1237/41 - FAX +39 029036.1331 Email: [email protected]

11. STOPPING AND DISMOUNTING

Before proceeding with these operations ensure that

the plant or machines have been put into the

conditions foreseen to allow these operations.

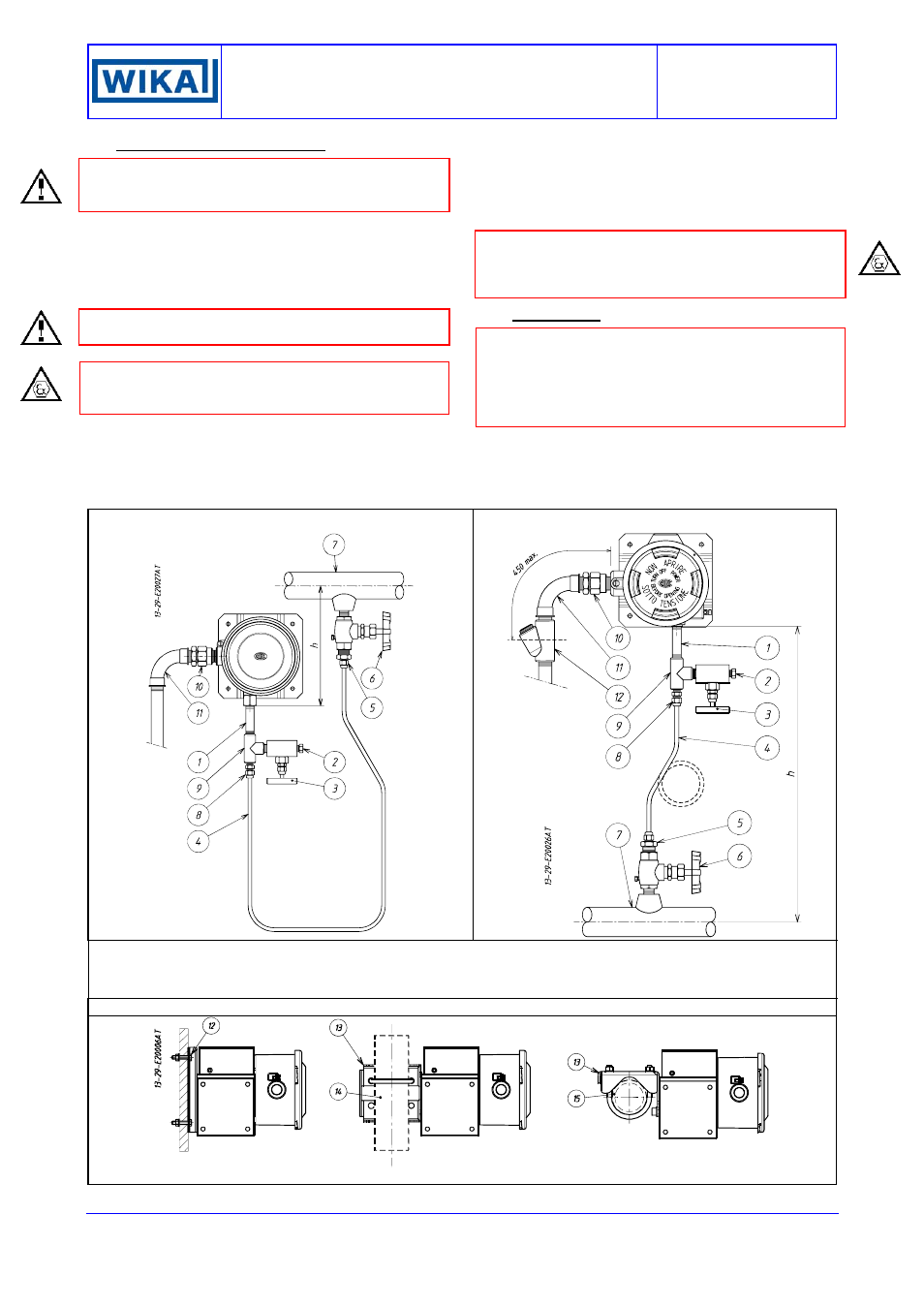

With reference to figures 8 and 9

Remove the power supply (signal) from the electrical

line. Close the root valve (6) and open the drain.

Remove the plug (2), open the valve (3) and wait until

the process fluid has drained from the tubing through

the drain.

Do not dispose of the process fluid into the environment,

if this can cause pollution or damage to people.

Unscrew the three-piece joint (8).

CAUTION: do not open the cover of explosionproof

pressure switches (Series APA) when energized, in

explosive atmospheres.

Unscrew the three-piece joint (10) (electrical cable

tubing).

Remove the instrument cover and disconnect the

electrical cables from the terminal block and earth

screws. Remove the screws fixing the case to the panel

(or pipe) and remove the instrument, taking care to slide

the electrical conductors out from the case.

Replace the instrument cover. Insulate and protect the

conductors remaining on the plant. Temporarily plug the

tubing (4).

In case of explosionproof instruments (Series APA) it is

recommended to follow - at least – the standard EN-

60079-17 for the withdrawal from service of electrical

apparatus.

12. DEMOLITION

The instruments are mainly made of stainless steel and

aluminium and therefore, once the electrical parts have

been dismounted and the parts coming into contact with

fluids which could be harmful to people or the

environment have been properly dealt with, they can be

scrapped.

WEATHERPROOF EXPLOSIONPROOF

Fig. 8 -

Example of connections -

Fig. 9 -

Example of connections -

1 – Fitting

2 - Drain plug

3 - Service valve

4 - Piping

5 - Three piece fitting

6 - Root valve with drain

7 - Process piping

8 - Three piece fitting

9 - “T” fitting

10 - Three piece fitting

11 - Curve

12 - Blocking joint

13 - M6 screws (No. 4)

14 - Bracket for 2” pipe

15 - Vertical pipe

16 - Horizontal pipe

Fig. 10 -

Example of mounting

Montaggio a parete

Montaggio su staffa per tubo da 2”

Surface mounting

2” pipe mounting