Instruction manual ni-205 – WIKA APA10 User Manual

Page 5

INSTRUCTION MANUAL

NI-205

Rev. 1 12/02

6.4

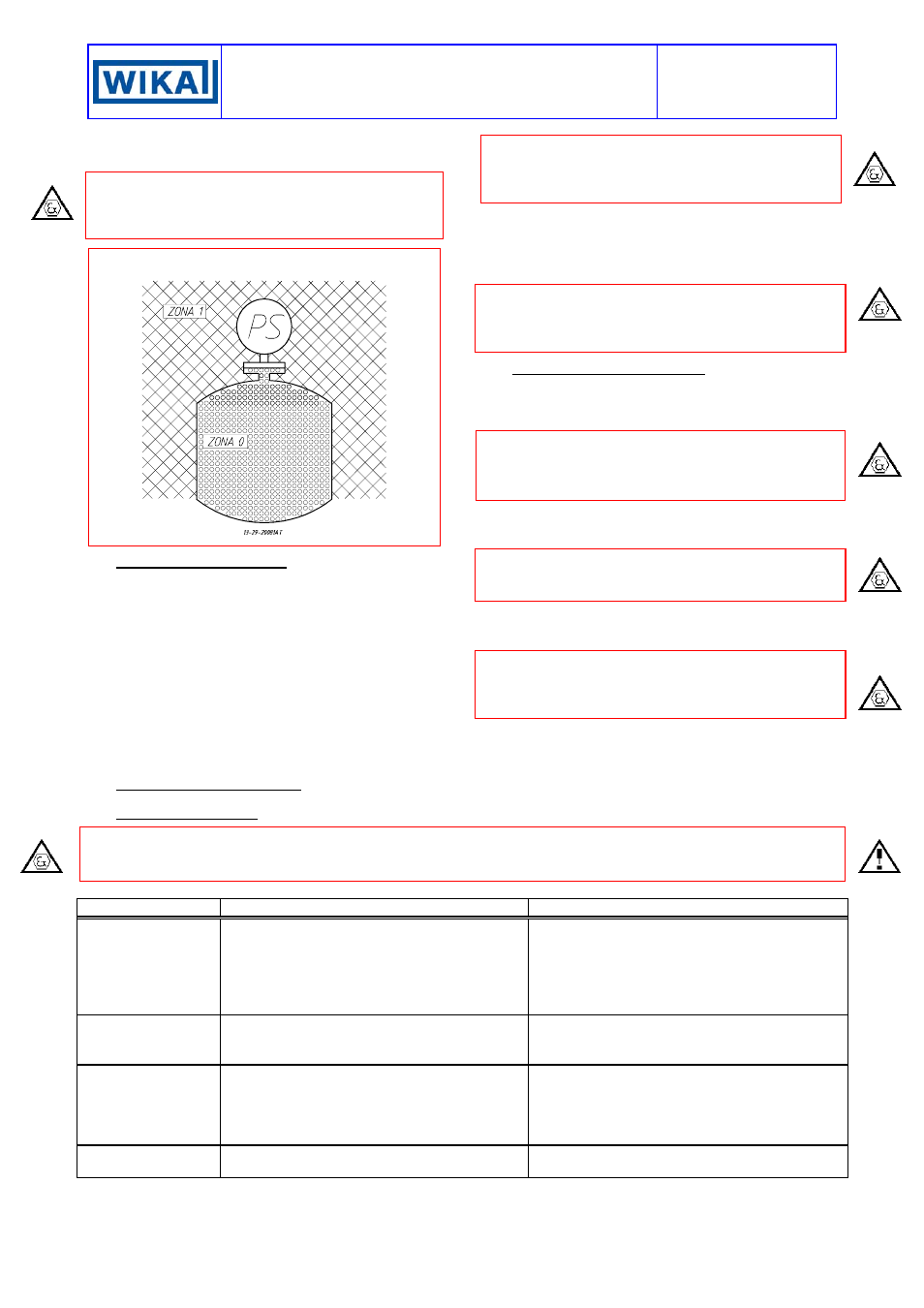

SPECIAL NOTE FOR INSTALLATION OF

CATEGORY 1 / 2 G PRESSURE SWITCHES

Explosionproof pressure switches (Series APA) can be

installed on processes requiring apparatus of group II

category 1 in an ambient requiring apparatus of group II

category 2 (see Fig. 7).

Fig. 7 -

Installation of Group II Cat. 1 / 2 G instruments

7. INSTRUMENT

PLUMBING

Weatherproof pressure switches (Series APW)

The plumbing, aimed as a guarantee against possible

tampering of the calibration and electrical connections,

can be carried out using a flexible steel wire (a) inserted

into the holes in the screw (c) and the bracket (d)

provided for this purpose (see Fig. 4).

Explosionproof pressure switches (Series APA)

Plumbing is not necessary as the cover is blocked with a

headless screw, the closure plugs of the adjustment

screw access holes are blocked by means of the

internal blocking device and the instrument does not

have to be opened when installed (see Fig. 5).

8. PUTTING INTO OPERATION

As the signal transmitted by the instrument is used in a

complex system, it is necessary that the means of

putting it into operation are established by those in

charge of the plant.

The instrument comes into operation as soon as the root

valve is opened. Any possible drainage of the

connection tubing can be carried out by removing the

safety plug and opening the service valve with the

necessary caution.

In case of explosionproof instruments (Series APA),

initial inspections are to be carried out according to

customer procedures and at least in accordance with

Standard EN-60079-17.

9. FUNCTIONAL

VERIFICATION

This will be carried out according to the Client’s control

procedures. Series APW instruments can be verified on

the plant if installed as illustrated in Fig. 8 or 9.

The instruments Series APA may be checked on site

only if apparatus suitable for explosive atmospheres are

used and provided that the electric line is not

energized.

If this is not the case it is necessary to stop operation,

dismount by means of the three-piece joints and carry

out the verification in a test room.

CAUTION: do not open the cover of explosionproof

pressure switches (Series APA) when energized, in

explosive atmospheres.

Verification consists in checking the calibration value

and possibly regulating the adjustment screw (see

para.5).

In case of explosionproof instruments (Series APA),

inspections of the electrical installation are to be carried

out also according to customer procedures and at least

in accordance with Standard EN-60079-17.

10. TROUBLESHOOTING

IMPORTANT NOTE: operations involving replacement of essential components must be carried out at our

workshop, especially for instruments with explosionproof certificate; this is to guarantee the user the total and

correct restoration of the product original characteristics.

MALFUNCTION PROBABLE

CAUSE

REMEDY

Set point shift

Permanent deformation of the sensitive

element due to fatigue or non-tolerated

overranges.

Variation of the elastic features of the

sensitive element due to its chemical

corrosion.

Recalibrate or replace instrument with another

suitable for application.

Recalibrate or replace the instrument with

another having sensitive element made of a

suitable material.

Slow response

Clogged or obstructed connection line.

Root or service valves partially closed.

Check and clean line.

Open valves.

No actuation or

undue actuation

Root or service valves closed.

By-pass valve opened.

Microswitch contacts damaged.

Loosened electrical joints.

Interrupted or short-circuited electrical line.

Open the valves.

Close the valve.

Replace the Microswitch.

Check all electrical joints.

Check the conditions of the electrical line.

Undue actuation

Accidental shocks or excessive mechanical

vibrations.

Modify the mounting.