2 pneumatic installation, 5 commissioning, 6 operation – Festo Модули перемещения HSW User Manual

Page 4: 7 maintenance and care, 8 disassembly and repair, 9 accessories, 10 troubleshooting, 11 technical data

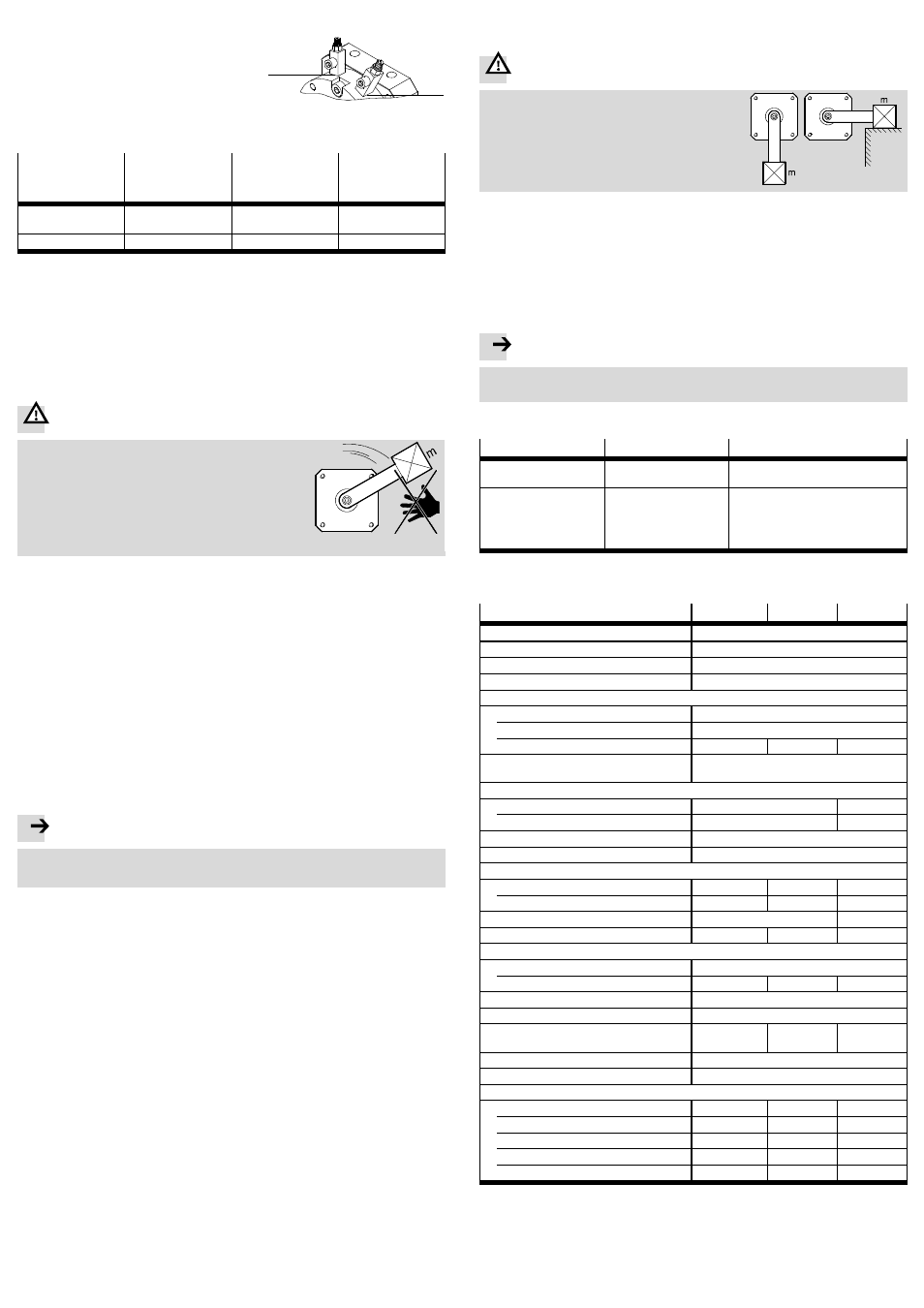

4.2 Pneumatic installation

• Use GRLA one-way flow control valves for

setting the swivel speed.

These are screwed directly into the com-

pressed air supply ports

2 (Fig. 7).

Fig. 7

2

2

During the swivel procedure, the following relationship between swivel speed and

flow control exists.

Factor

Supply air flow

control

Exhaust air flow

control

Supply and

exhaust air flow

control

Swivel speed

Increasing

Decreasing

Approach method

constant

Swivel time

Short

Long

Long

Fig. 8

For eccentric loads:

• Check whether HGL controlled non-return valves or a VZS air reservoir are ne-

cessary.

In this way you can prevent the useful load from sliding down suddenly if there

is a sudden pressure drop.

5

Commissioning

Warning

Danger of injury from rotating loads.

• Make sure that the DSM is set into motion only

with protective devices.

• Make sure that in the swivel angle of the DSM

– nobody can reach in

– no objects can enter (e.g. by means of an indi-

vidual protective guard).

1. Turn both upstream one-way flow control valves

– at first completely closed

– then open them again approximately one turn.

2. Make sure that the operating conditions lie within the permissible ranges.

3. Pressurize the drive optionally in one of the following ways:

–

slowly Pressurisation of one side

– simultaneous pressurisation of both sides with subsequent venting of one

side.

4. Start a test run.

5. During a test run check whether the following settings on the DSM need to be

modified:

– the swivel angle (only in combination with stop kit KSM-...)

– the swivel speed.

6. Slowly screw open the one-way flow control valves until the desired swivel

speed is set. The internal rotary vane should reach the end position safely, but

not strike hard against it.

Note

If the impact is too hard, it will cause rebounding out of the end position and a

reduction of the service life.

If the rotary vane audibly strikes hard:

7. Interrupt the test run.

Causes of hard impact may be:

– mass moment of inertia of the moving load too high

– swivel speed too high

– no compressed air cushion on the exhaust side.

8. Make sure you remedy the above-mentioned causes.

9. Repeat the test run.

When all necessary corrections have been made:

10. End the test run.

6

Operation

For several uninterrupted swivel cycles:

• Make sure that the maximum permissible swivel frequency is observed

(

Technical data).

Otherwise, the operational reliability will be impaired by excessive temperature

rise.

7

Maintenance and care

If the device is dirty:

• Clean the DSM with a soft cloth.

All non-abrasive cleaning agents are permissible (e.g. warm soap suds up to

+60 °C).

8

Disassembly and repair

For eccentric masses on the lever arm:

Warning

Risk of injury from masses that slide down sud-

denly if there is a drop in pressure.

• Make sure that the load has reached a stable

position before venting (e.g. the lowest

point).

Recommendation:

• Return the product to our repair service for overhaul. This way the fine tuning

and tests that are required will be taken into particular consideration.

Information about spare parts and accessories can be found at:

www.festo.com/spareparts.

9

Accessories

Note

• Please select the corresponding accessories from our catalogue

(

www.festo.com/catalogue).

10

Troubleshooting

Malfunction

Possible cause

Remedy

Uneven movement

Flow control valves

inserted incorrectly

– Check the flow control valve

functions (exhaust air flow control)

– Hard impact at the end

position

– Drive shaft does not

remain in the end

position

Residual energy too high

– Select lower swivel speed

– Use external shock absorbers

– Move only against residual air

cushion on the exhaust side

– Select lighter loads of the useful load

Fig. 9

11

Technical data

Size

6

8

10

Pneumatic connection

M3

Design

Swivel module with rotary vane

Type of mounting

With female thread

Mounting position

Any

Max. swivel frequency at 6 bar

DSM(-T)-…-90

[Hz]

3

DSM(-T)-…-180

[Hz]

3

DSM(-T)-…-240

[Hz]

–

–

2

Operating medium

Compressed air in accordance with

ISO 8573-1:2010 [7:4:4]

Min. operating pressure

DSM

[bar]

3.5

2.5

DSM-T

[bar]

4

3.5

Max. operating pressure

[bar]

8

Ambient temperature

[°C]

0 … +60

Theoretical torque at 6 bar

DSM

[Nm]

0.15

0.35

0.85

DSM-T

[Nm]

0.3

0.7

1.7

Permissible stop radius r

min

[mm]

10

13

Permissible stop force F

max

[N]

15

30

60

Max. permissible force on the drive shaft

Axial force F

X

[N]

10

Radial force F

Z

[N]

15

20

30

Note on materials

Free of copper and PTFE

Material information and product weight

www.festo.com/catalogue

Permissible mass moment of

inertia

1)

[10

–5

kg m

2

]

0.5

1.0

2.0

Cushioning

Flexible cushioning at both ends

Cushioning angle

[°]

0.5

Swivel angle

2)

DSM(-T)-…-90

[°]

90

+ 5 3)

90

+ 5

90

+ 5

DSM(-T)-…-180

[°]

0 … 180

+ 5 3)

0 … 180

+ 5

0 … 180

+ 5

DSM(-T)-…-240

[°]

–

–

0 … 240

+ 5

DSM(-T)-…-180-…-FF-…

[°]

0 … 180

+ 5 3) 4)

0 … 180

+ 5 4)

–

DSM(-T)-…-240-…-FF-…

[°]

–

–

0 … 200

+ 5 4)

1)

Unthrottled.

2)

Adjustment of swivel angle at DSM(-T)-… only with accessories.

3)

Only adjustable symmetrical to the centre.

4)

Precision adjustment (–5

…

+1°) via adjusting screw.

Fig. 10