Unpacking your fence assembly, Sawstop, Owner’s manual – SawStop Premium Fence Assembly User Manual

Page 3: Fence assembly hardware pack, Sawstop premium fence assembly 1, Sawstop, llc

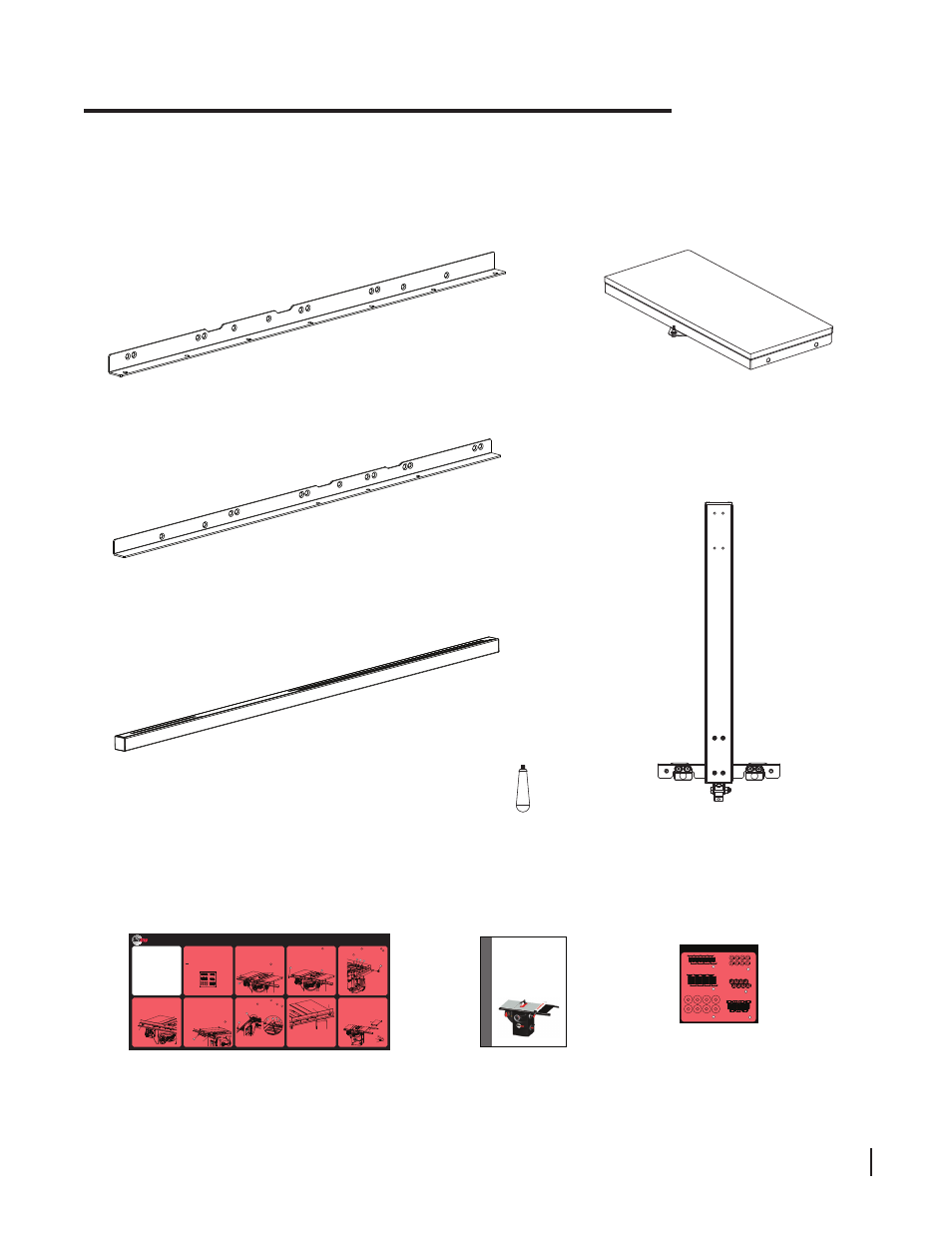

Unpacking Your Fence Assembly

While unpacking your fence assembly, verify that all of the components on this page are included. Use care

when unpacking your fence assembly to prevent damage to any of the components.

main tube

front rail

rear rail

extension table

installation instructions poster

owner’s manual

fence handle

fence assembly

hardware pack

premium rip fence

10

90

10

20

30

40

50

0

60

70

80

90

10

20

30

40

50

60

70

80

20

90

10

20

30

40

50

60

70

80

30

90

10

20

30

40

50

60

70

80

400

90

10

20

30

40

50

60

70

80

500

90

10

20

30

40

50

60

70

80

600

90

10

20

30

40

50

60

70

80

700

10

20

30

40

50

60

0

10 20 30

40 50 60

70 80 90

100

10 20 30

40 50 60

70 80 90

200

10 20 30

40 50 60

70 80 90

300

SawStop

SawStop

®

OWNER’S MANUAL

Premium Fence Assembly

Fence Assembly Hardware Pack

2

Flat Head Socket Bolts,

M8x1.25x25 (8)

Flat Head Socket Bolts,

M8x1.25x16 (8)

1

Washers,

M8x23x2 (15 + 1 extra) 3

Lock Washers,

M8 (15 + 1 extra) 4

Hex Nuts,

M8x1.25 (8) 5

6

Hex Head Bolts,

M8x1.0x16 (7)

Installing Your SawStop Premium Fence Assembly

SawStop Service Department

503-582-9934

www.sawstop.com

© SawStop, LLC

4

9

3

2

1

8

5

6

7

Before assembling your Premium Fence

Assembly, make sure that you have all the

necessary components identified on page 1

in the owner’s manual, including the fence

assembly hardware pack. Call the SawStop

Service Department at 503-582-9934 if any

components are missing. You will also need

the following tools to complete the fence

assembly installation:

1. a 3 mm hex key

2. a 5 mm hex key

3. a 13 mm wrench

4. a straight-edge

• Locate the front rail, the rear rail, and the fence assembly

hardware pack. All of the hardware needed to install the fence

system is located on the fence assembly hardware pack. In

order to easily identify the hardware used in each of the

following steps, the different pieces of hardware are numbered

on the hardware pack and in the figures.

Note: Your saw must be fully assembled before installing the

fence system.

• Take the front rail (the larger of the two rails) and align it to

the front edge of your saw by centering the notches in the rail

with the two miter slots in the table and aligning the two holes

between the notches with the two corresponding holes in the

front edge of the table. Aligning the two holes between the

notches aligns all the other holes used in mounting the front

rail to your saw; different holes are used for different saws.

When the holes are aligned, mount the front rail to the saw by

taking four M8x1.25x16 flat head socket bolts and threading

one into each of the four threaded holes in the front edge of

the main table. Tighten the four bolts using a 5 mm hex key.

1

miter slots

1

front rail

notches

• Take two M8x1.25x25 flat head socket bolts and insert

one through the open hole at the end of each extension wing.

2

2

2

• Place an M8x23x2 washer and an M8 lock washer on

the back of each of the M8x1.25x25 flat head socket bolts

that extend through the extension wings, and then thread an

M8x1.25 hex nut on each bolt. Hand tighten the nuts; do

not fully tighten them.

3

4

2

5

SawStop

System Status

Codes

Status

Red

Grn

Wet Wood

Overload D

ue To

During Bypa

ss

Contact Dete

cted

During Stan

dby

Contact Dete

cted

Brake

Adjust Positi

on of

Doors

Close Acces

s

Key To “On”

Turn Cartrid

ge

To “Off”

Turn Start S

witch

Bypass Mod

e On

Coasting Do

wn

Replace Ca

rtridge

System Rea

dy

System Initia

lizing

• • • • • •

• • • • • •

• • • • • •

• • • • • •

• • • • • •

• • • • • •

• • • • • •

2

3

4

5

• Use a straight-edge to level the front edge of the left

extension wing to the cast iron table top. You may have to pull

up or push down on the outer edge of the extension wing to

level it. Once the front edge of the left extension wing is level,

use a 5 mm hex key and a 13 mm wrench to fully tighten the

nut on the bolt that mounts the left extension wing to the front

rail. Repeat this process to level the front edge of the right

extension wing.

straight-edge

level the extension

wing and tighten the

nut on this bolt

• Take the rear rail (the smaller of the two rails) and align it to

the rear edge of your saw by centering the notches in the rail

with the two miter slots in the table and aligning the left-most

hole between the notches with the corresponding hole in the

rear edge of the table. There are three holes in the rail

between the notches, one solitary hole and two holes paired

together, and the left-most hole is the solitary hole. Not all of

the holes are used to mount the rail to your saw; different

holes are used for different saws. Aligning the left-most hole

aligns all the other holes used in mounting the rear rail to your

saw. When the holes are aligned, mount the rear rail to the

saw by taking four M8x1.25x16 flat head socket bolts and

threading one into each of the four threaded holes in the rear

edge of the main table. Tighten the four bolts using a 5 mm

hex key.

!

WARNING

Movin

g gear

s and p

arts

can pin

ch, cu

t or cru

sh.

Do no

t oper

ate w

ith

door o

pen.

align the left-most

hole between

the notches

1

1

!

WA

RN

ING

Mo

vin

g g

ea

rs

an

d p

ar

ts

ca

n p

in

ch

, c

ut

or

cru

sh

.

Do

no

t o

pe

ra

te

w

ith

do

or

op

en

.

• Take two M8x1.25x25 flat head socket bolts and insert

one through the open hole at the end of each extension wing.

Place an M8x23x2 washer and an M8 lock washer on

the back of each of bolt and then thread an M8x1.25 hex nut

on each bolt. Hand tighten the nuts; do not fully tighten them.

2

3

4

5

2

5

4

3

2

2

• Use a straight-edge to level the rear edge of the left

extension wing to the cast iron table top. You may have to pull

up or push down on the outer edge of the extension wing to

level it. Once the rear edge of the left extension wing is

level,

use a 5 mm hex key and a 13 mm wrench to fully

straight-edge

level the extension

wing and tighten the

nut on this bolt

Fence Assembly Hardware Pack

2

Flat Head Socket Bolts,

M8x1.25x25 (8)

Flat Head Socket Bolts,

M8x1.25x16 (8)

1

Washers,

M8x23x2 (15 + 1 extra) 3

Lock Washers,

M8 (15 + 1 extra) 4

Hex Nuts,

M8x1.25 (8) 5

6

Hex Head Bolts,

M8x1.0x16 (7)

• The next step of the assembly is easiest with two people.

Position the extension table between the front and rear rails.

Make sure that the table is oriented so that the adjustment

bracket is closest to the right extension wing. Tilt the extension

table slightly so that the adjustment bracket can fit under the

edge of the extension wing. Position the extension table so

that the end of the adjustment bolt aligns with the

corresponding threaded hole in the bottom of the extension

wing. With the weight of the extension table still supported,

turn the adjustment bolt until the extension table is roughly

flush with the extension wing.

adjustment

bolt

adjustment

bracket

adjustment

bracket

SawStop Premium Fence Assembly 1