Caution – Comfort-Aire FMG****F1E Series User Manual

Page 6

6

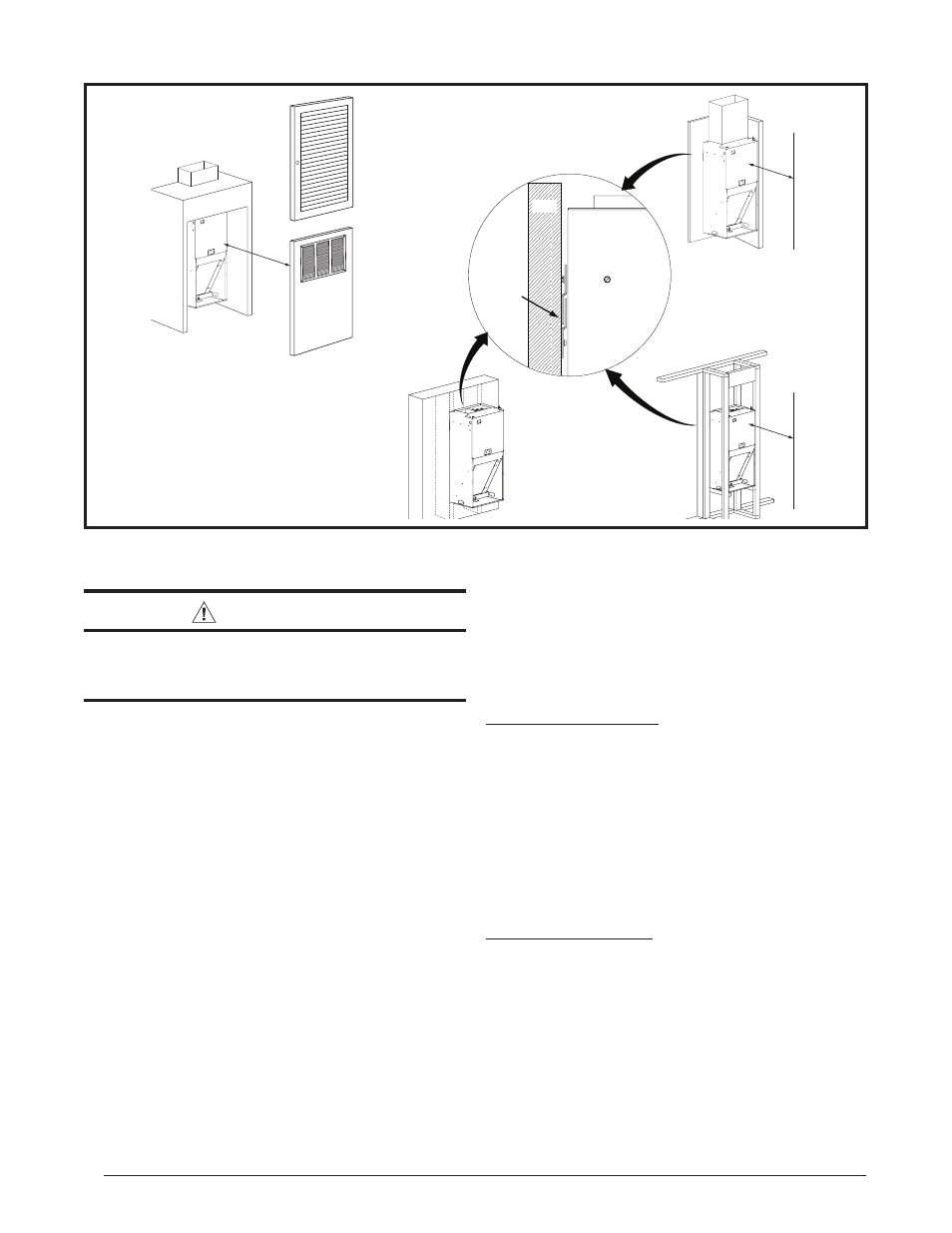

18"

(457 mm)

24” Clearance from

nearest wall or

partition

Full Louvered

Door

Wall

Mount

Closet

Installation

Alcove

Installation

6”

(152mm)

Typical Closet Door

with Return Air Grill

Installed

OR

Recessed

Wall

Wall

2-Piece

Mounting

Bracket

24” Clearance from

nearest wall or

partition

Figure 1. Unit Installation

CAUTION:

This unit uses refrigerant R-410A. DO NOT use

any other refrigerant in this unit. Use of another

refrigerant will damage the unit.

• Every effort should be made by the installer to ensure

that the field installed refrigerant containing components

of the system have been installed in accordance with

these instructions and sound installation practices to

insure reliable system operation and longevity.

• Always refer to the installation instructions supplied with

the outdoor unit for piping requirements. The suction

and liquid lines must be sized in accordance with the

condensing unit specifications. See Figure 4 (page 12)

for liquid and suction line locations.

• When connecting refrigerant linesets together, it is

recommended that dry nitrogen be flowing through the

joints during brazing. This will prevent internal oxidation

and scaling from occurring.

• Refrigerant tubing should be routed in a manner that

minimizes the length of tubing and the number of bends

in the tubing. It should be supported in a manner that

prevents it from vibrating or abrading during system

operation. Tubing should be kept clean of foreign debris

during installation.

• If precise forming of refrigerant lines is required, a copper

tubing bender is recommended. Avoid sharp bends and

contact of the refrigerant lines with metal surfaces.

• Refrigerant lines should be wrapped with pressure

sensitive neoprene or other suitable material where

they pass against sharply edged sheet metal.

• The FMG air handler is charged through a Schrader

valve on the end of the liquid tube. This must be removed

before brazing the line sets.

System Depressurization

1. Remove the cap from the end of the liquid line.

2. Verify pressurization by depressing the Schrader valve

on the end of the liquid line. Listen for any escaping gas.

If there is no pressure, test the unit for leakage.

• If leakage is found, clearly mark the location of the leak

and return the unit to the distributor for processing.

• If no leaks are found, the air handler may be installed.

3. Depress the valve to relieve all pressure from the coil.

4. Remove the Schrader valve housing from the end of

the liquid tube by unbrazing or using a tube cutter.

Connecting the Linesets

Notes: Before proceeding, perform steps 1 - 3 in the

System Depressurization section.

1. Route and cut both lineset tubes to proper length in

accordance with the outdoor unit specifications. Verify

the ends are round, clean, and free of any burrs.

2. Connect the suction and liquid lineset tubes.