Installation, Leveling, Grouting – Bell & Gossett P81630F Series VSCS Base Mounted Centrifugal Pumps User Manual

Page 4: Rotation, Coupler alignment

4

INSTALLATION

This pump is built to provide years of service if installed properly

and attached to a suitable foundation. A base of concrete weigh-

ing 2

1

/

2

times the weight of the pump is recommended. (Check

the shipping ticket for pump weight.)

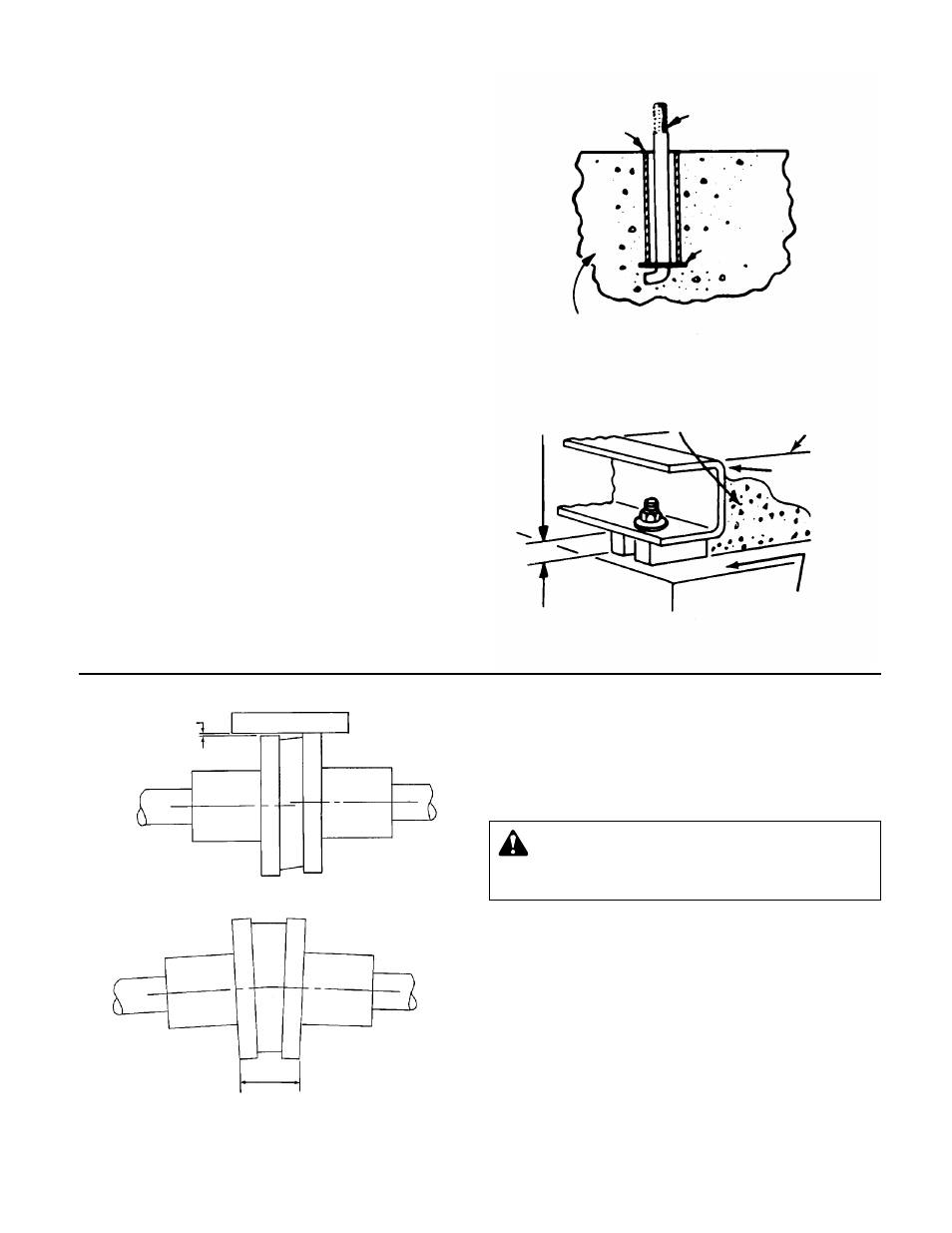

If possible, tie the concrete pad in with the finished floor. Use

foundation bolts and larger pipe-sleeves to give room for final

bolt location. (See Figure 6A.)

LEVELING

Place the pump on its concrete foundation supporting it with

steel wedges or shims totaling 1" in thickness. These wedges

or shims should be put on both sides of each anchor-bolt to

provide a means of leveling the base. (See Figure 6B.)

It is very important that the pump-base be set level to avoid any

mechanical difficulties with the motor or pump. This pump was

properly aligned (if furnished with a motor) at the factory. How-

ever, since all pump bases are flexible they may spring and twist

during shipment. Don’t pipe the pump until it is realigned. After

piping is completed and after the pump is grouted-in and bolted-

down, align it again. It may be necessary to re-adjust the align-

ment from time to time while the unit and foundation are new.

GROUTING

After the pump has been leveled, securely bolted to the floor,

and properly aligned, a good grade of non-shrinking grout

should be poured inside the pump base. To hold wedges or

shims in place, allow the grout to flow around them.

ROTATION

The VSC & VSCS pump is available in both right- and left-hand

rotation. An arrow cast into the pump body shows the direction

of rotation.

COUPLER ALIGNMENT

All alignment should be done by moving or shimming the motor

only. Adjustments in one direction may alter alignment in another.

Therefore, check alignment in all directions after a correction is

made. Black rubber inserts have different horsepower load

ratings than orange Hytrel sleeves. They should not be

interchanged.

STANDARD SLEEVE TYPE COUPLER

WITH BLACK RUBBER INSERT

Before aligning the coupler, make sure there is about

1

/

8

" end

clearance between the sleeve and the two coupler halves.

1. Check angular misalignment using a micrometer or caliper.

Measure from the outside of one flange to the outside of the

opposite flange at four points 90° apart. DO NOT ROTATE

COUPLER. Misalignment up to

1

/

64

" per inch of coupler

radius is permissible.

2. At four points 90° apart (DO NOT ROTATE COUPLER), mea-

sure the parallel coupler misalignment by laying a straight

edge across one coupler half and measuring the gap

between the straight edge and opposite coupler half. Up to a

1

/

64

" gap is permissible.

PIPE

SLEEVE

FOUNDATION

BOLT

BUILT-UP

CONCRETE FOUNDATION

GROUT ONLY TO

TOP OF BASE RAIL.

PUMP

BASE RAIL

APPROX.

1" GAP

CONCRETE

FOUNDATION

LEVELING OF PUMP BASE

ON CONCRETE FOUNDATION.

GROUT

FIGURE 6A

WASHER

FIGURE 6B

ALLOW 1" FOR SHIMS.

PLACE ON BOTH SIDES

OF ANCHOR BOLTS.

NOTE:

TO KEEP SHIMS IN

PLACE ALLOW GROUT

TO FLOW AROUND

HOLD DOWN LUGS.

WARNING: Unexpected Startup Hazard

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in serious

personal injury or death, or property damage.

ANGULAR ALIGNMENT CHECK

AMOUNT OF

PARALLEL

MISALIGNMENT

STRAIGHT EDGE

PARALLEL ALIGNMENT CHECK

DISTANCES ACROSS

COUPLER FLANGES

SHOULD BE EQUAL

(CHECK 4 PLACES)