Bell & Gossett AC8584D Series HSCS Base Mounted Centrifugal Pumps User Manual

Page 22

2

2

6. Place the sleeve O-ring (3-914-9) onto the shaft, into the

sleeve counterbore. Verify that Dimension “A” (Figure 12) is

maintained, then using a pin spanner wrench and hammer,

securely tighten the shaft sleeve nuts (3-015-9). Then, drill

a shallow recess in the shaft through the set screw hole in

each of the shaft sleeve nuts. Lock each shaft sleeve nut

in position with cup point set screws (3-902-9). (See Figure

15) A low strength sealant, such as Loctite 271, can be

used to retain set screws.

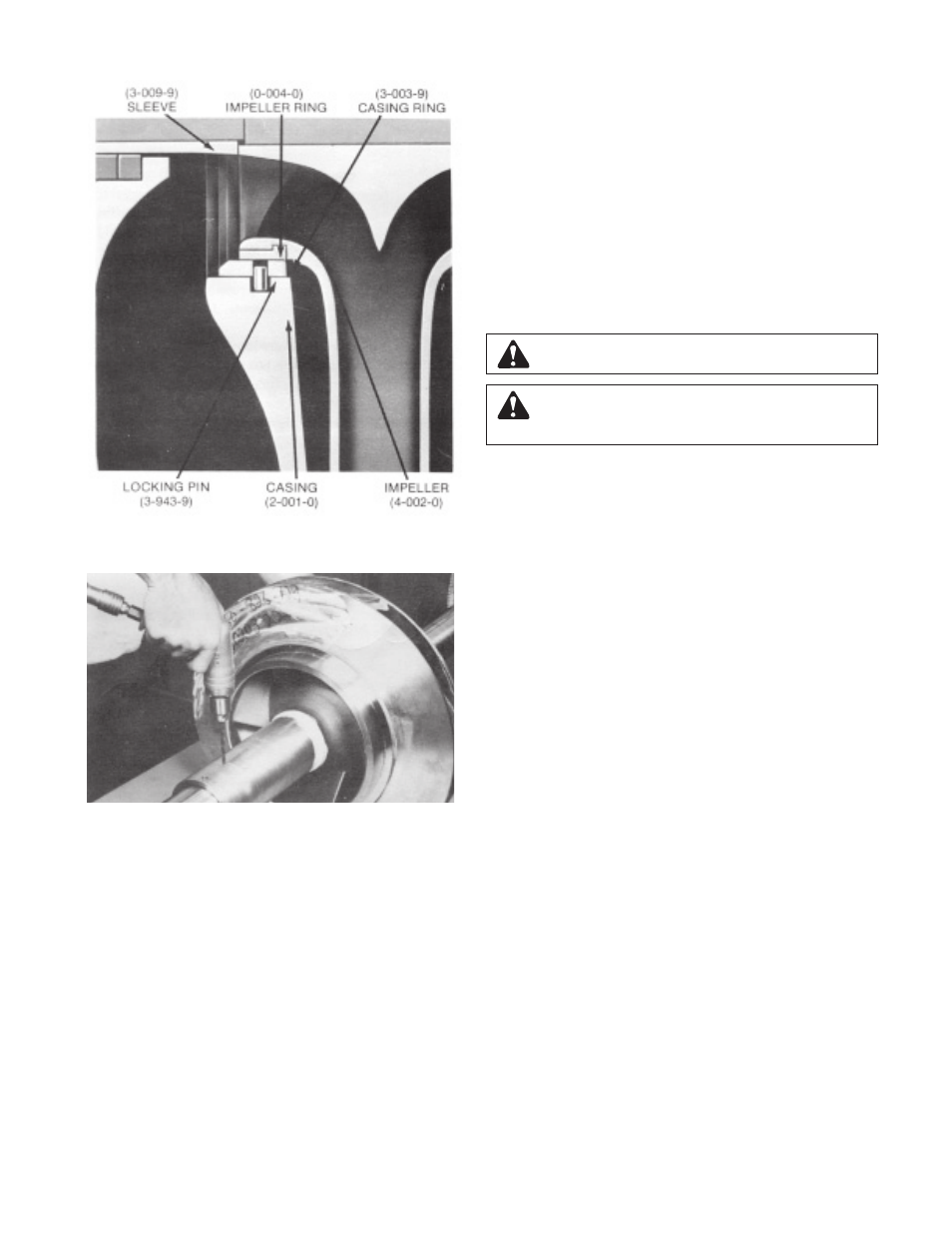

7. Assemble casing rings (3-003-9). (See page 26 for

adjustable rings.)

8. Start heating bearings (3-026-2) so that they will be ready

when called for in step 11. Use dry heat from induction

heat lamps from electric furnace, or a 10-15% soluble oil

and water solution.

9. Assemble oil seals (3-177-9) in each bearing cover. Install

gaskets (3-409-9) on each bearing cover.

56;,! Seal lip or pressure side of oil seal must point

towards the end of the shaft that the oil seal is assembled

on. (See Figures 25 and 26)

10. Slide deflectors (3-136-9) and bearing covers (3-018-3, -4)

on the shaft. Install snap rings (3-915-9). Install thrust

washer (3-078-9) on the outboard end.

For ease of assembly and protection of rubber parts while

sliding rubber parts onto shaft, cover O-ring groove, key-

ways, and thread with electric tape.

56;,! Inboard bearing cover (3-018-3) is approximately

1/4 inch less in width than the outboard bearing cover

(3-517-4). This is the only dimensional difference.

11. Press heated bearing (3-026-2) on shaft against snap ring

or thrust washer. Install locknut (3-516-4) and lockwasher

(3-517-4) on outboard end. Make certain locknut is

secured and then bend over tab on lockwasher.

12.

7<47:>0;/.9,(:,3<)90*(;065

Cool bearings at room temperature and coat with 2 or 3

ounces of a recommended grease.

7<47:>0;/6033<)90*(;065

Refer to page 26 for installation of oil lubricated parts.

13. Assemble oil seals (3-177-9) in each bearing housing.

Refer to

56;, under number 9 above for direction of oil

seal.

14. Slide bearing housings (3-025-2) onto shaft (3-007-0) over

bearings (3-0262).

*(<;065!DO NOT EXCEED 275°F.

*(<;065!These are precision, high quality bearings.

exercise care at all times to keep them clean and free

from foreign matter.

-0.<9,¶*(:05.(5+047,33,9905.:

-0.<9,¶+903305.:,;:*9,>9,*,::