Bell & Gossett AC8584D Series HSCS Base Mounted Centrifugal Pumps User Manual

Page 16

16

Regrease the grease-lubricated bearings

It is important to lubricate pumps and motors that require regreasing

with the proper grease. See the motor service instructions and

nameplate for motor regreasing information. Pumps are to be

regreased using the grease types listed below or approved equal.

Always keep pump and motor properly lubricated.

NOTICE:

Make sure the grease container, the greasing device, and the

fittings are clean. Failure to do so can result in impurities entering

the bearing housing when you regrease the bearings.

1. With fully enclosed coupling guards, regrease pump while pump

is running.

a. With old style open ended guards, stop pump, re-grease,

and hand turn shaft before re-starting.

2. Wipe dirt from the grease fittings before greasing.

3. Fill both of the grease cavities through the fittings with the

recommended grease. Stop when grease leaks out at shaft.

4. If needed, stop pump and wipe off excess grease.

5. Restart pump.

The bearing temperature usually rises after you regrease due

to excess supply of grease. Temperatures return to normal in

about two to four operating hours as the pump runs and purges

the excess grease from the bearings. Maximum normal bearing

housing temperature for polyurea-based grease is 225°F (107°F)

and for lithium-based grease 180°F (82°C).

Lubricating grease requirements

NOTICE:

• Never mix grease of different consistencies (NLGI 1 or 3 with

NLGI 2) or with different thickeners. For example, never mix

lithium-based grease with a polyurea-based grease. This can

result in decreased performance.

• Remove the bearings and old grease if you need to change

the grease type or consistency. Failure to do so can result in

equipment damage or decreased performance.

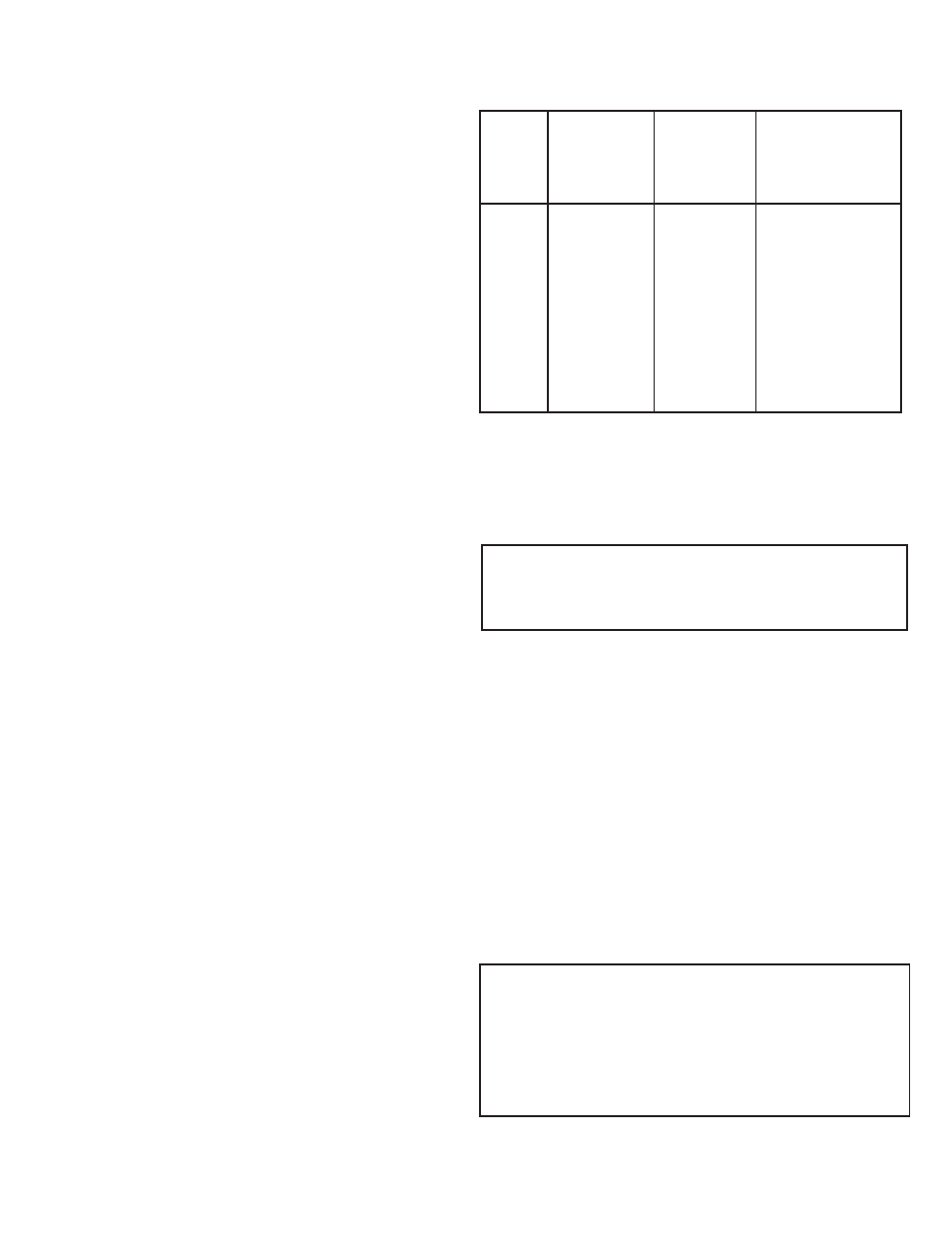

Type of

bearing

First lubrication,

assembled

pumps and

replacement

bearing frames

First

lubrication,

replacement

bearings

Lubrication interval,

pump, polyurea-based

grease, operating hours

Grease-

lubricated

bearings

Not applicable,

lubricated before

shipment

Hand pack

bearings before

pressing on

the shaft. After

bearing frame

assembly,

follow relube

instructions to

lube bearings.

• 3600 hours, 2 pole

• 7200 hours, 4 pole

• 50% for severe

conditions: dirty, wet

and/or above 100°F

(38°C) ambient

• 50% for bearing frame

temperature above

180°F (82°C)

• 75% for lithium-based

grease

BEARING MAINTENANCE

3. Bearing lubrication schedule

MAINTENANCE

1. General Maintenance

Operating conditions vary so widely that to recommend one

schedule of preventative maintenance for all centrifugal

pumps is not possible. Yet some sort of regular inspection

must be planned and followed. We suggest a permanent

record be kept of the periodic inspections and maintenance

performed on your pump. This recognition of maintenance

procedure will keep your pump in good working condition,

and prevent costly breakdown.

One of the best rules to follow in the proper maintenance of

your centrifugal pump is to keep a record of actual operating

hours. Then, after a predetermined period of operation has

elapsed, the pump should be given a thorough inspection.

The length of this operating period will vary with different

applications,and can only be determined from experience.

New equipment, however, should be examined after a relatively

short period of operation. The next inspection period can

be lengthened somewhat. This system can be followed until

a maximum period of operation is reached which shouldbe

consideredthe operating schedule between inspections.

2. Maintenance of Pump Due to Flood Damage

The servicing of centrifugal pumps after a flooded condition is

a comparatively simple matter under normal conditions.

Bearings are a primary concern on pumping units. First, dismantle

the bearings; clean and inspect them for any rusted or badly worn

surfaces. If bearings are free from rust and wear, reassemble and

relubricate them with one of the recommended pump lubricants.

Depending on the length of time the pump has remained in the

flooded area, it is unlikely that bearing replacement is necessary;

however, in the event that rust or worn surfaces appear, it may be

necessary to replace the bearings.

Next, inspect the stuffing box, and clean out any foreign matter

that might clog the box. Mechanical seals should be cleaned and

thoroughly flushed.

Couplings should be dismantled and thoroughly cleaned.

Any pump that is properly sealed at all joints and connected to

both the suction and discharge should exclude outside liquid.

Therefore, it should not be necessary to go beyond the bearings,

stuffing box, and coupling when servicing the pump.