Reassembly – Goulds Pumps CV 3171 - IOM User Manual

Page 41

CV 3171 IOM 05/11

41

REASSEMBLY

Refer to Table 7 for torque values while reassembling pump.

Table 7

BOLT TORQUE TABLE

Location

Lubricated Threads

Dry Threads

Casing Bolts (370)

30 FT-LBS (40 Nm)

45 FT-LBS (60 Nm)

Column Pipe to

Adapter Bolts (370G)

20 FT-LBS (27 Nm)

30 FT-LBS (40 Nm)

Steady Bearing

Bolts (372B)

20 FT-LBS (27 Nm)

30 FT-LBS (40 Nm)

Column Pipe to

Motor Mount (370M)

20 FT-LBS (27 Nm)

30 FT-LBS (40 Nm)

Motor Mount to

Support Plate (370L)

30 FT-LBS (40 Nm)

45 FT-LBS (60 Nm)

Motor to

Motor Mount (371)

20 FT-LBS (27 Nm)

30 FT-LBS (40 Nm)

Strainer to Case (317N)

20 FT-LBS (27 Nm)

30 FT-LBS (40 Nm)

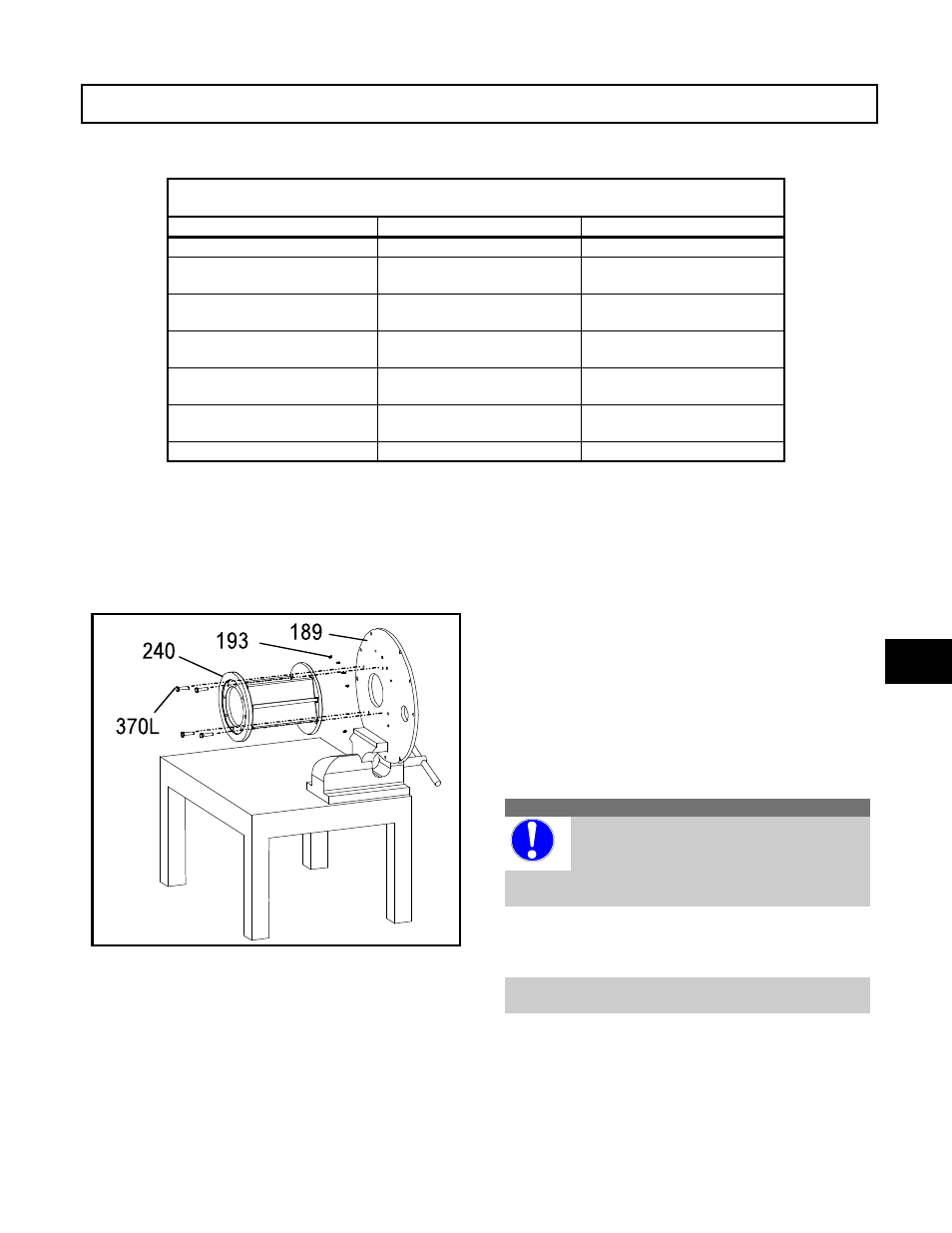

ASSEMBLY OF MOTOR SUPPORT,

HEAD COLUMN, AND SUPPORT PLATE

1. If motor support disassembled, attach motor

support (240) to support plate (189) with bolts

(370L) (Figure 33).

2. Attach head column (192) to motor support with

bolts (370M). Vent holes should be closer to the

motor support.

OPTIONAL WITH STUFFING BOX

DESIGN

Refer to Figure 48, Appendix II.

1. Attach stuffing box (221) to support plate (189)

with bolts (370L).

2. Attach motor support (240) to stuffing box with

bolts (370J).

3. Attach head column (192) to stuffing box with

bolts (370M). Vent holes should be closer to the

motor support.

ASSEMBLY OF ROTATING ELEMENT

CAUTION

Shafts can be damaged by improper

handling. Extreme care should be taken

at all times. It is recommended that

shafts over 9 feet long be handled by two people

at all times to prevent possible bending.

1. Install retaining ring (369A) on shaft (122)

(Figure 34).

NOTE: S/ST groups do not use the 369A

retaining ring.

2. Install thrust bearing (112) on shaft (122).

Figure 33

6