Installation, Inspection – Goulds Pumps CV 3171 - IOM User Manual

Page 15

CV 3171 IOM 05/11

15

INSTALLATION

INSPECTION ......................................................................................................................... 15

SITE/FOUNDATION .............................................................................................................. 16

WHEN PIT COVER IS USED................................................................................................. 16

NO PIT COVER...................................................................................................................... 17

IMPELLER CLEARANCE SETTING ..................................................................................... 17

MOTOR INSTALLATION AND COUPLING ALIGNMENT ................................................... 17

PIPING ................................................................................................................................... 19

INSPECTION

Equipment that will operate in a

potentially

explosive

environment must be installed

in accordance with the following

instructions.

All equipment being installed

must be properly grounded to

prevent

unexpected

static

electric discharge. If not, a static

electric discharge may occur when the

pump is drained and disassembled for

maintenance purposes.

Service temperature in an

ATEX classified environment

is limited by Table 1 in the

ATEX identification section.

1. Remove all equipment from shipping

containers.

2. Completely clean the underside of the

support plate, and both sides of the

optional pit cover (if supplied).

3. Remove any grease from machined

surfaces if applicable.

CAUTION

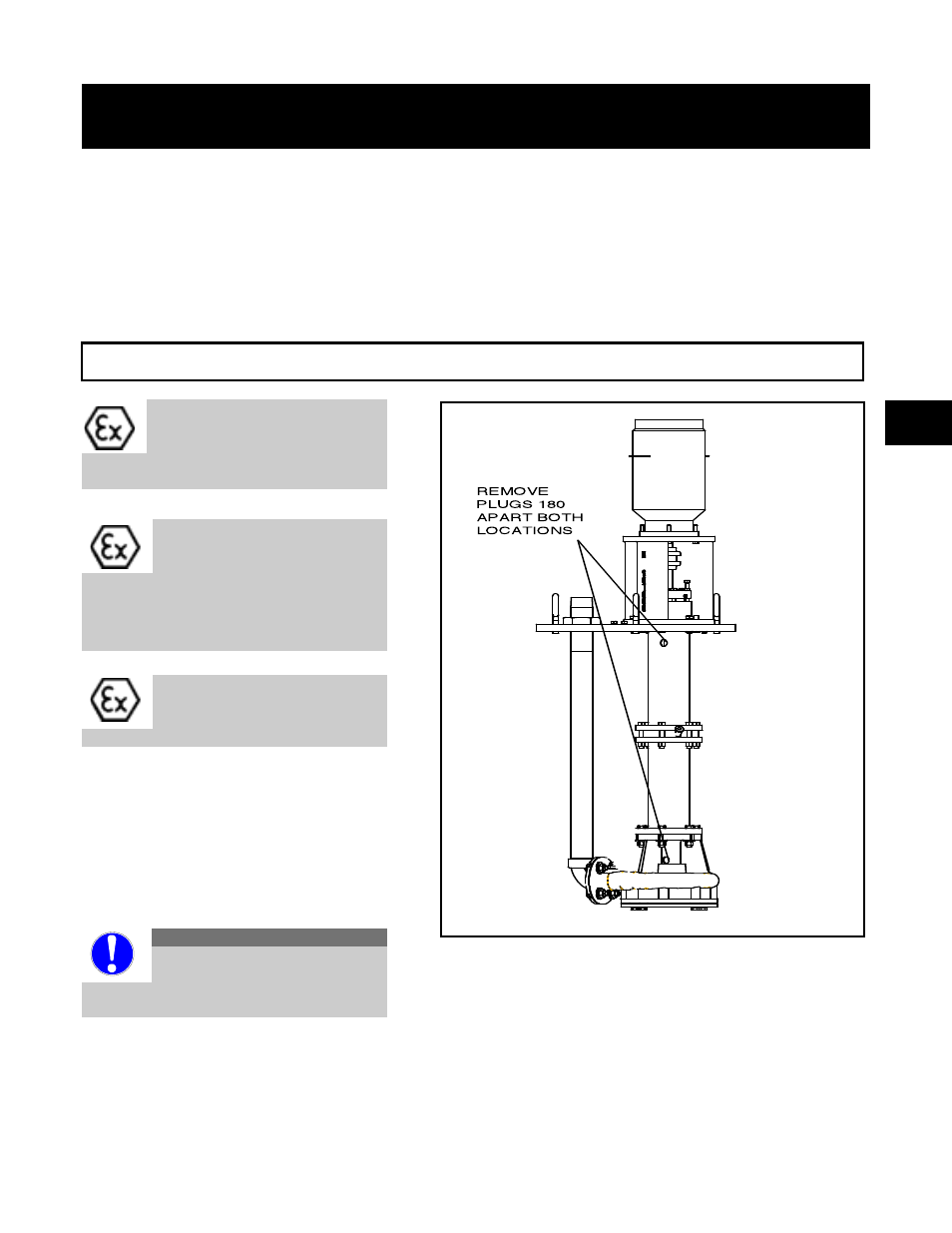

Remove plastic shipping plugs

from the vent holes in the head

column and casing. Refer to Figure 4 for

locations.

3

Figure 4