No pit cover, Impeller clearance setting, Motor installation and coupling alignment – Goulds Pumps CV 3171 - IOM User Manual

Page 17

CV 3171 IOM 05/11

17

NO PIT COVER

Standard Support Plates

1. Carefully lower the pump and support plate onto

the foundation bolts.

2. Level the support plate in all directions using

shims and wedges.

3. Hand tighten the anchor bolts, check the level

and re-shim if necessary.

4. Tighten all anchor bolts in a star pattern to avoid

distorting the support plate.

5. Assure that the support plate is level.

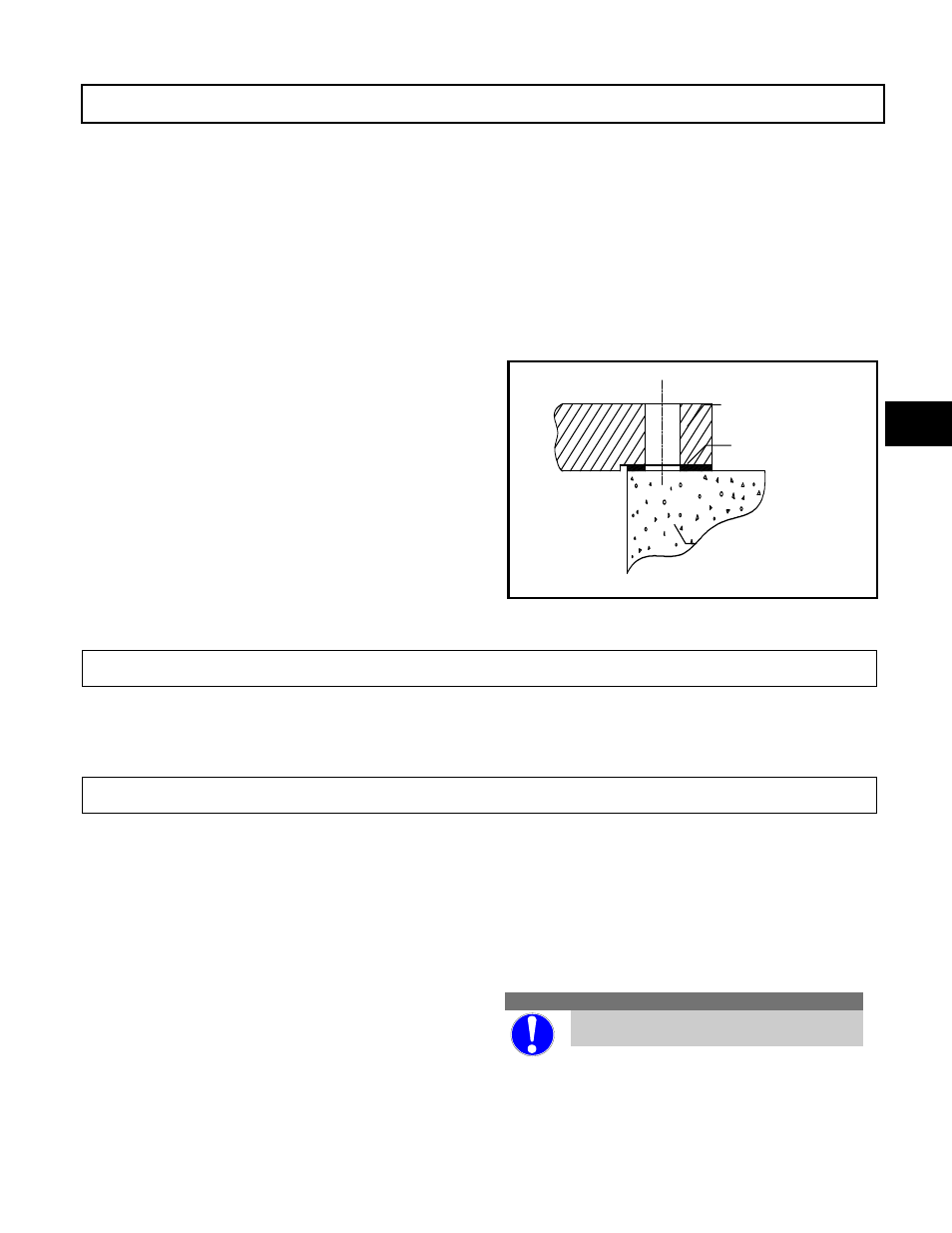

Vapor Proof Option

The support plate/foundation fit is a gasketed fit.

The support plate should be bolted to a metal sole

plate with a machined surface to insure an airtight

seal. Refer to Figure 6 for standard layout. A gasket

is supplied for installation between the two flanges

to insure an airtight fit.

Tank Flange Support Plates

1. Mating flange on the tank must be level. Very

minor adjustments can be made with gasket

material between the two flanges.

2. Install all bolts finger tight.

3. Tighten all bolts in a star pattern to avoid any

distortion of the support plate.

IMPELLER CLEARANCE SETTING

Adjust the impeller clearance setting. This

procedure is easiest to perform without the motor

and coupling installed. See Section 5, “Impeller

Clearance Setting” for proper procedure.

MOTOR INSTALLATION AND COUPLING ALIGNMENT

The Model CV3171 is designed for use with NEMA

Vertical C-face motors. P-Base motor adapters and

IEC motor adapters are available as options.

Installation

1. Install both coupling halves prior to mounting

the motor. Refer to the coupling manufacturers

instructions.

2. Using the lifting lugs on the motor, carefully

lower the motor onto the pump and align the

bolt holes.

3. Install motor bolts and finger tight.

4. Before the coupling is connected, the motor

must be wired and the direction of rotation

checked. A rotation arrow is located on the

motor support. Correct rotation for the pump is

CW looking down from the driver at the

impeller.

Checking Rotation

CAUTION

Serious damage may result if pump is

run in the wrong direction.

Figure 6

3

FOUNDATION

GASKET

189