Inspections, Casing, Rotor – Goulds Pumps 3501 Mixer - IOM User Manual

Page 38: Seal chamber, Bearing frame, Table 7, Table 8

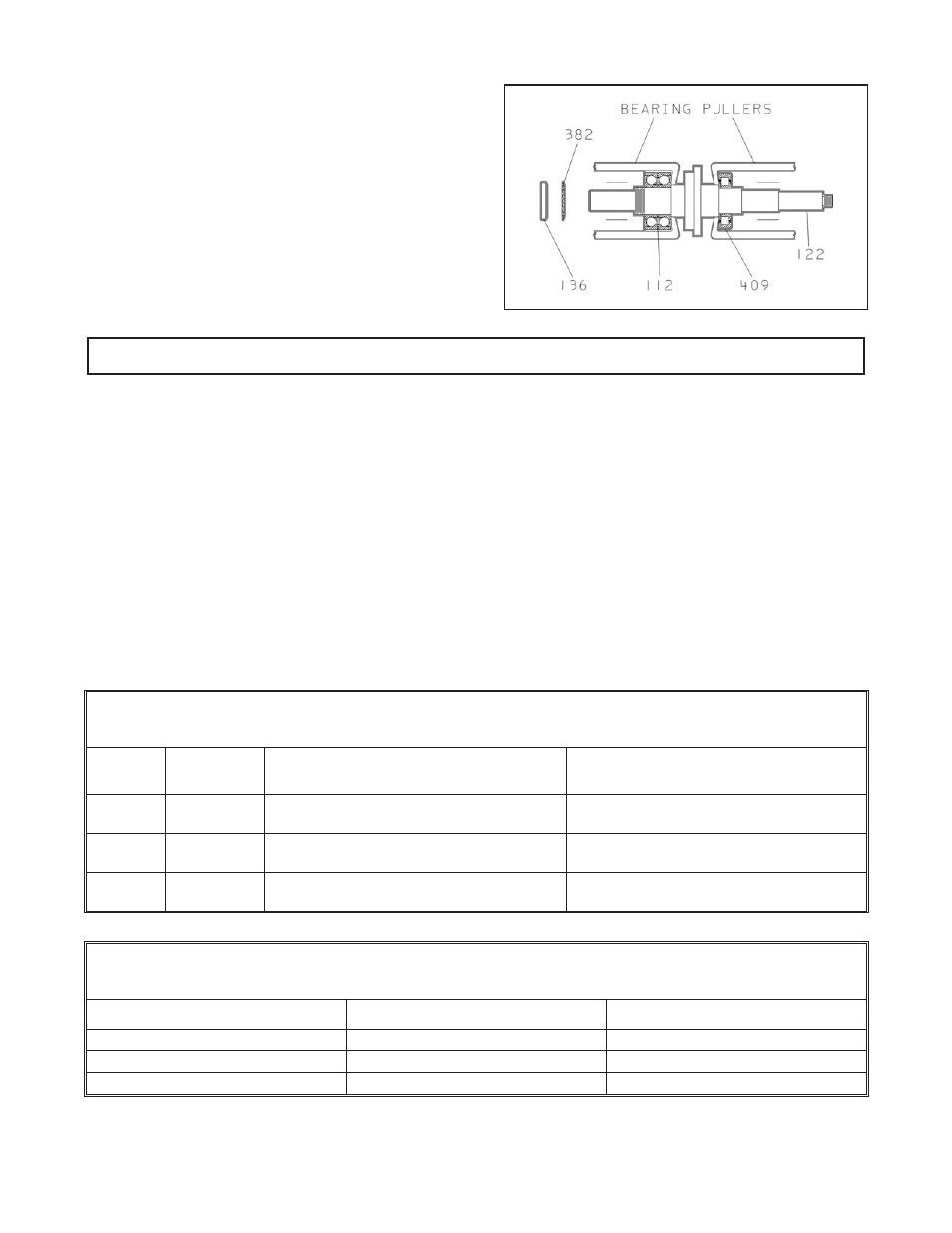

10. Disengage thrust bearing lock washer (382) from

locknut (136) and remove both from shaft (122)

(Fig 34).

11. Remove bearings (112, 409) from shaft (122) using a

suitable puller that only contacts inner races of

bearings (Fig. 34).

INSPECTIONS

CASING

1.

Thoroughly clean gasket surfaces and alignment fits

to remove rust and debris.

2.

Inspect for any unusual erosive wear inside casing.

ROTOR

1.

Inspect leading and trailing edges of vanes for

pitting, and erosion or corrosion damage.

2.

Inspect keyway and bores for damage.

SEAL CHAMBER

1.

Thoroughly clean gasket surfaces and fits to remove

rust and debris.

2.

Inspect surface for pitting, and erosion or corrosion

damage.

BEARING FRAME

1.

Inspect frame and frame foot for cracks.

2.

Inspect for corrosion or pitting if frame has been

exposed to the fluid.

3.

Inspect frame bearing bores per Table 7.

4.

Inspect labyrinth seal o-rings for cuts and cracks.

5.

Inspect shafts and sleeves for wear.

34

3501 IOM 11/10

Fig. 34

Table 7

Bearing Frame

GROUP

BEARING

Maximum Bearing Frame (228) Bore

mm(inch)

Maximum Bearing Housing (134A) Bore

mm (inch)

M

Thrust

Radial

160.02 (6.3002)

130.03 (5.1191)

130.03 (5.1191)

L

Thrust

Radial

200.15 (7.8752)

150.11 (5.9065)

160.02 (6.3002)

XL

Thrust

Radial

240.03 (9.4500)

180.09 (7.0876)

189.99 (7.4815)

Table 8

Bearing Sizes

GROUP

THRUST BEARING

RADIAL BEARING

M

7312BECBY

NUP312ECP

L

7315BECBY

NUP314ECP

XL

7318BECBY

NUP317ECP