Mixer washdown, Feeler gauge method – Goulds Pumps 3501 Mixer - IOM User Manual

Page 33

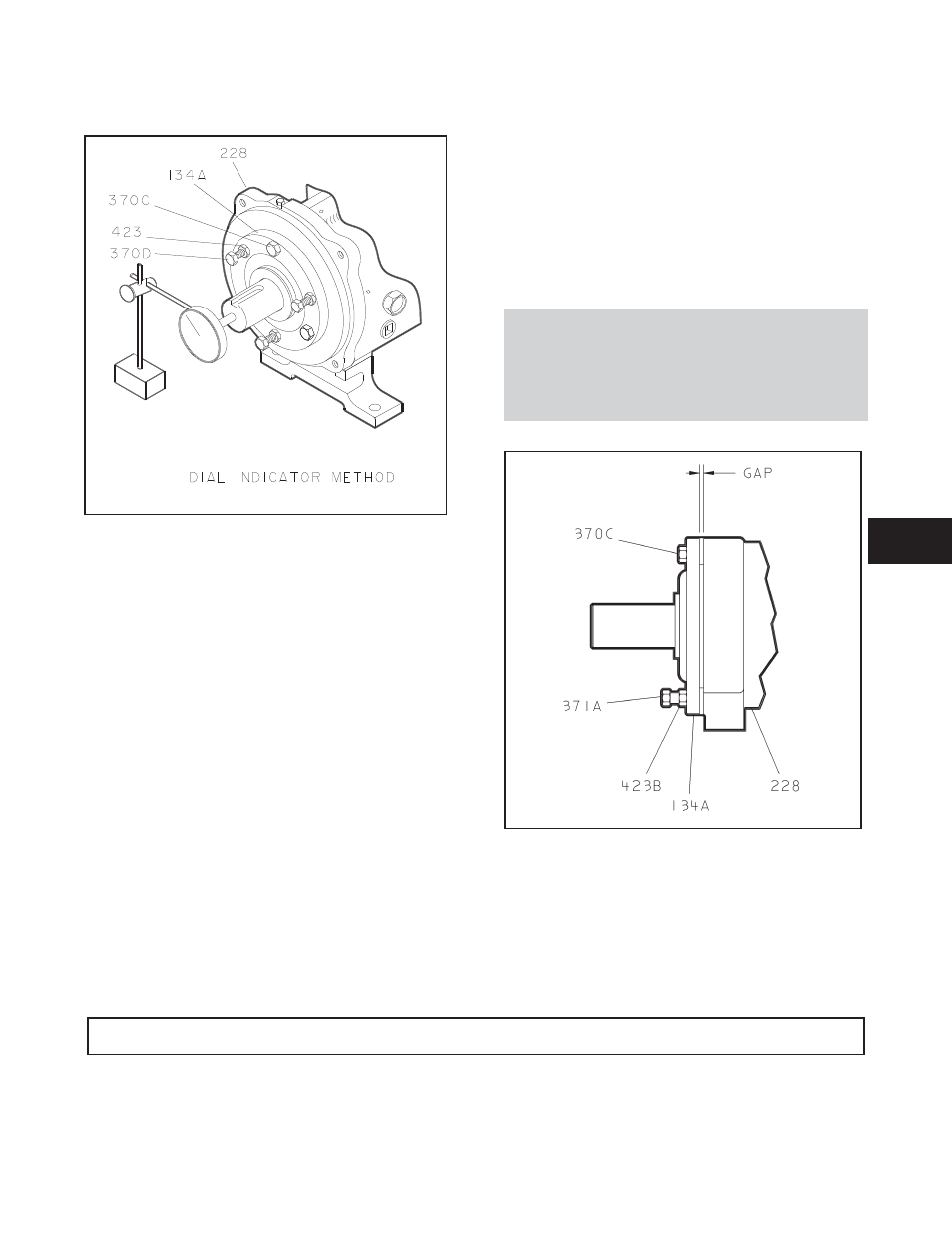

FEELER GAUGE METHOD

1.

Remove coupling guard.

2.

Loosen jam nuts (423B) on adjuster bolts (371A) and

back bolts out about two turns.

3.

Tighten locking bolts (370C) evenly, drawing

bearing housing (134A) towards frame (228) until

rotating assembly bottoms out.

4.

With a set of feeler gauges, measure and record the

gap between the bearing housing (134A) and the

bearing frame (228) (Fig. 24).

5.

Back locking bolts (370C) off a couple of turns.

6.

Thread jack bolts (371A) in until they contact the

bearing frame (228) evenly. Tighten the jack bolts

evenly (about one flat at a time), backing the bearing

housing (134A) away from the bearing frame until

the rotating assembly contacts the seal chamber cover

(184).

7.

Using the feeler gauges, measure and record the gap

between the bearing housing (134A) and the bearing

frame (228).

8.

Average the two gap measurements and set the feeler

gauge stack to that number.

9.

Loosen jack bolts (371A) several turns.

10. Insert feeler gauge stack into gap between bearing

housing (134A) and bearing frame (228). Tighten the

locking bolts (370C) evenly until bearing housing

contacts the feeler gauge stack.

11. Evenly tighten jack bolts (371A), then locking bolts

(370C) while assuring that the feeler gauge does not

bind or become loose.

12. Tighten jam nuts (423B).

13. Check shaft for free turning.

14. Replace coupling guard.

NOTE: For pumps supplied with cartridge

mechanical seals, be sure the set screws in the seal

locking ring have been tightened and the centering

clips removed prior to startup. Failure to take these

steps could result in damage to the mechanical seal or

shaft sleeve.

MIXER WASHDOWN

These mixers are designed to prevent liquid from entering the bearing frame. Care should be taken, however, to avoid

spraying a high pressure stream directly at the labyrinth frame seals.

3501 IOM 11/10

29

5

Fig. 24

Fig. 23