Grease lubricated bearings, Table 5 grease amounts, Caution – Goulds Pumps 3501 Mixer - IOM User Manual

Page 31

GREASE LUBRICATED BEARINGS

Grease lubricated bearings are pre-lubricated at the

factory. We recommend regreasing bearings every 2000

operating hours or 3 months. Refer to

Table 5 for

re-grease amounts.

Table 5

Grease Amounts

Frame

Initial Grease

Regrease

1

Thrust

(Angular

Contact)

Radial

(Cylindrical

Roller)

Thrust

(Angular

Contact)

Radial

(Cylindrical

Roller)

Grams

Oz.

Grams

Oz.

Grams

Oz.

Grams

Oz.

M

290

10

180

7.0

115

4.0

70

2.5

L

475

17

280

10

200

7.0

115

4.0

XL

800

28

450

16

345

12.0

190

6.5

1

Amount is based on purging half of the old grease from the

housing reservoir.

Regrease Procedure:

NOTE: When regreasing, there is danger of

impurities entering the bearing housing. The grease

container, the greasing device, and fittings must be

clean.

1.

Wipe dirt from grease fittings.

2.

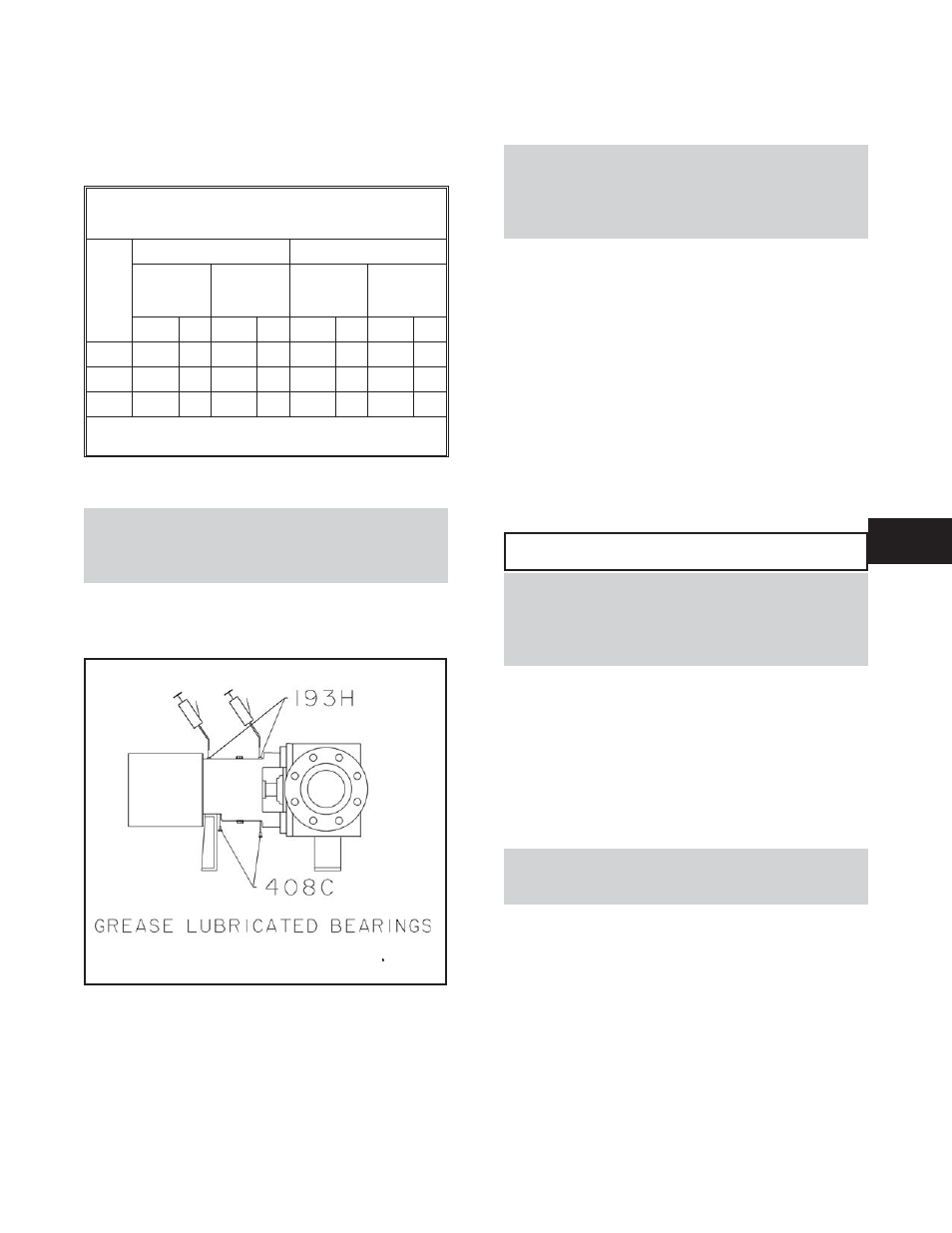

Remove two (2) grease relief plugs (408C) (Fig. 22).

3.

Fill both grease cavities through fittings with

recommended grease until fresh grease comes out of

the relief holes (408C).

4.

Ensure frame seals (332A, 333B) are seated in

bearing housing and, if not, press in place with drains

located at the bottom.

5.

Run mixer for about 2 hours or until grease stops

emitting from housing and replace two (2) relief

plugs (408C).

NOTE: The bearing temperature usually rises after

regreasing due to an excess supply of grease.

Temperatures will return to normal after mixer has

run and purged the excess from the bearings, usually

two to four hours.

For most operating conditions a lithium based mineral oil

grease of NLGI consistency No. 2 is recommended. This

grease is acceptable for fluid temperatures of -15°C to 110°C

(5°F to 230°F). Bearing temperatures are generally about

25°C (45°F) higher than bearing housing outer surface

temperature.

Acceptable Greases:

Mobil

Mobilux EP2

Exxon

Unirex N2

Texaco

Multifak 2

Shell

Alvania 2 EP

Grease 2

Sunoco

Multipurpose EP

SKF

LGMT 2

p

!

CAUTION

Never mix greases of different consistency (NLGI 1

or 3 with NLGI 2) or different thickener soaps

(sodium or calcium with lithium). The consistency

usually becomes softer and will not provide adequate

lubrication to the bearings.

For operating temperatures above 110°C (230°F) the

bearings should be lubricated with a high temperature

grease. Mineral oil greases should have oxidation

stabilizers and a consistency of NLGI 3.

Acceptable Greases:

Exxon

Unirex N3

SKF

LGHT3

NOTE: If these greases are used, disassemble the

bearing housing, degrease the bearings and housing

prior to greasing.

3501 IOM 11/10

27

5

Fig. 22