Overview – Dow Protected Membrane Roof EN User Manual

Page 3

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

O

V

E

R

V

I

E

W

2

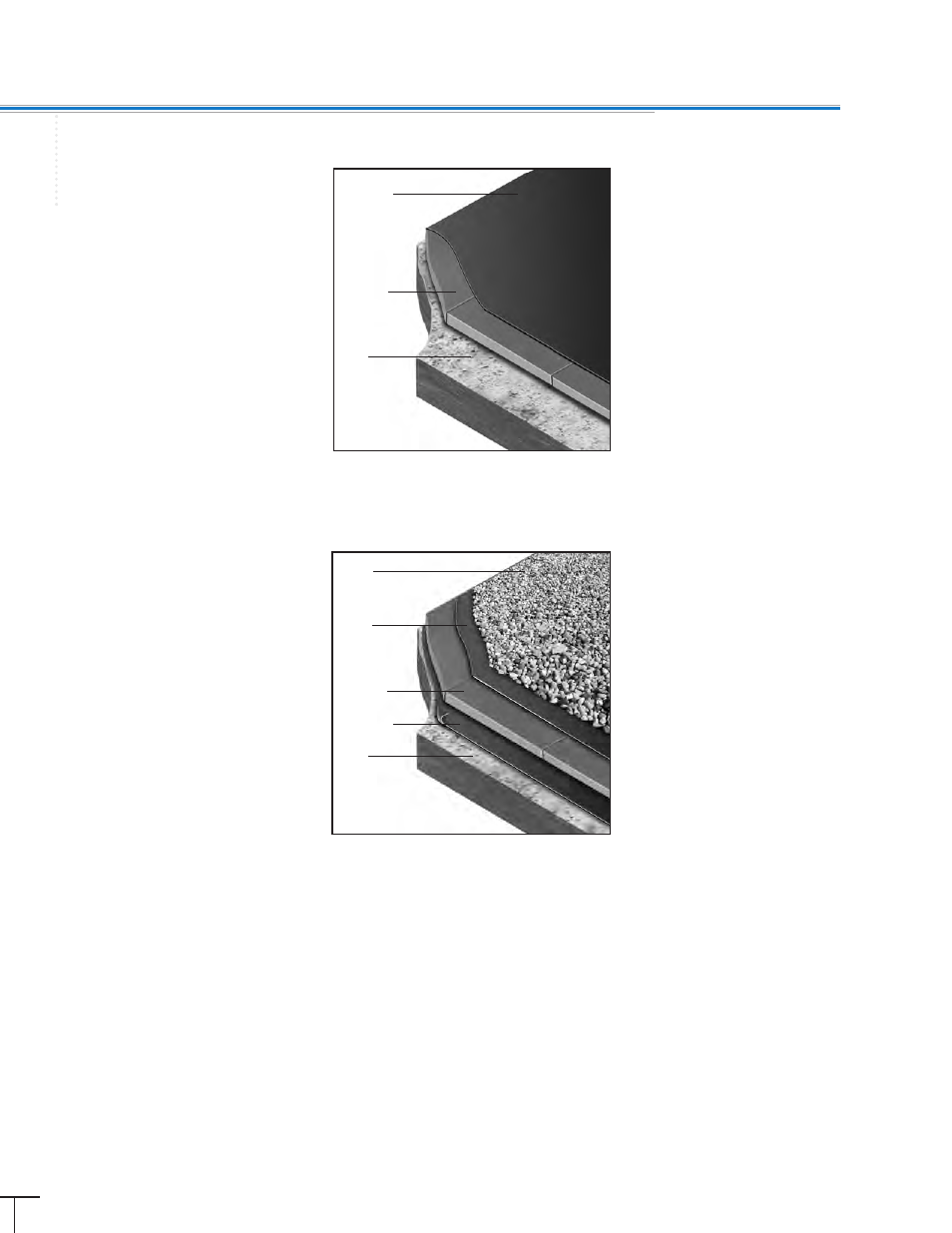

Protected membrane roofing’s

breakthrough contribution to

flat roof technology was the

incorporation of an “upside-

down” approach to insulating

the roof: placing the insulation

on top of the waterproof mem-

brane to improve the membrane’s

effectiveness and the insulation’s

efficiency.

This advancement was made

possible in large part by the use

of STYROFOAM

™

extruded poly-

styrene insulation, whose

closed-cell, water-resistant quali-

ties have proven to be a key

component in protected mem-

brane roof (PMR) systems.

A conventional roof places

the membrane on top of the

insulation, leaving the mem-

brane vulnerable to extreme

temperature changes, freeze-

thaw conditions and physical

abuse from heavy foot traffic

(Figure 1).

The PMR system places the

insulation on top of the mem-

brane, protecting the roofing

membrane from extreme tem-

perature changes and physical

abuse (Figure 2).

The main difference between

PMR and conventional roofing

is the sequence in which the

materials are applied. The key

to the PMR system is that the

insulation is placed on top of

the waterproofing membrane.

This configuration protects the

membrane, resulting in superior

long-term performance and

durability.

Figure 1: Conventional Roof With Membrane Above

the Insulation (depending upon building and climate

conditions, a vapor barrier may also be used)

Figure 2: PMR With Membrane Below the Insulation

Ballast

Filter

Fabric

STYROFOAM™

Extruded

Polystyrene

Insulation

Membrane

Deck

Membrane

STYROFOAM™

Extruded

Polystyrene

Insulation

Deck

Overview

C H A N G I N G

T H E

S E Q U E N C E