Components, Description, Function – Dow Protected Membrane Roof EN User Manual

Page 11

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

C

O

M

P

O

N

E

N

T

S

–

B

a

l

l

a

s

t

1 0

Description

Crushed stone or washed,

rounded riverbed rock, ASTM

D448 Gradation #2, 4, 5 or 57

depending on membrane type,

building height, wind zone and

parapet height (Table 2).

Depending on the ballast

design, the range of ballast is

10 to 15 lb/ft

2

with additional

ballast around perimeters and

penetrations (15 to 20 lb/ft

2

). In

some cases, pavers can be used.

See “Pavers” on page 12 for

additional details.

Function

Prevent uplift and prevent

flotation: The amount and

placement of ballast is based on

the following considerations:

• Design wind speed – Refer to

the ANSI/ASCE 7-95 wind

speed map, contact the local

code authority for the design

wind speed for the building

location or refer to TechNote

508: “Ballast Design Guide for

IRMA Roofs”

• Roof height – Use the worst-

case elevation (e.g., from

ground level to the highest

point of the roof)

• Parapet height – Measured

from the top of the ballast to

the top of the parapet, use the

shortest parapet height in any

variation

• Membrane type – Adhered,

loose-laid or mechanically

attached

Areas of extra ballasting:

Extra ballast, required to overcome

high wind loads and restrain

insulation during heavy rain-

storms, should be considered in

the following locations:

• Perimeter edge – 8.5' wide

band running along the

perimeter edge of the roof

insulation. As an alternate to

additional ballast, 1 to 4 rows

of concrete pavers may be

installed along the perimeter

edge (see TechNote 508).

• Penetrations through the insu-

lation – 4' wide band around

any roof penetration greater

than 4' in any direction (e.g.,

skylights, equipment pads, etc.).

• Corners – Concrete pavers may

be required with steel strap-

ping and anchors for certain

designs (see TechNote 508).

See “Pavers” on page 12 for

details about concrete pavers.

• Building exposure – Consider

the surrounding terrain and its

potential effect on the overall

wind exposure (e.g., nearby

woods versus shorelines).

• Membrane type – Adhered,

mechanically fastened or fully

ballasted. For additional

details, see “All Other

Components” on page 13.

Prevent wind scouring: The

wind performance of stone bal-

lasted PMRs has been excellent.

Only a few isolated minor scour-

ing problems have occurred,

typically limited to small areas

in a corner. In these few cases,

the ballast has blown inbound

by about 4' and piled up on the

filter fabric, creating additional

weight.

Prevent UV degradation of

the insulation: Most PMR appli-

cations use a filter fabric that

typically incorporates a UV

stabilizer. However, if no fabric

is used, the insulation must be

totally covered by the ballast to

prevent UV degradation. The

quality of the ballast is very

critical in these types of applica-

tions. Too small (fines not more

than 10 percent of mix) and

the stones may work into the

insulation joints or be moved

by the wind; too large and the

ballast may not provide adequate

cover to protect from UV light.

Provide a Class A fire-resistant

roof cover: Class A roof covering,

as defined by ULC S107, ULI

790 and ASTM E108. (See “Fire

and Wind Ratings” on page 20

for additional details.) The

requirements for Class A roof

construction cover the perform-

ance of roof assemblies and roof

covering materials when

exposed to a fire originating

from sources outside a building.

The stone ballast or pavers

provide the Class A fire rating.

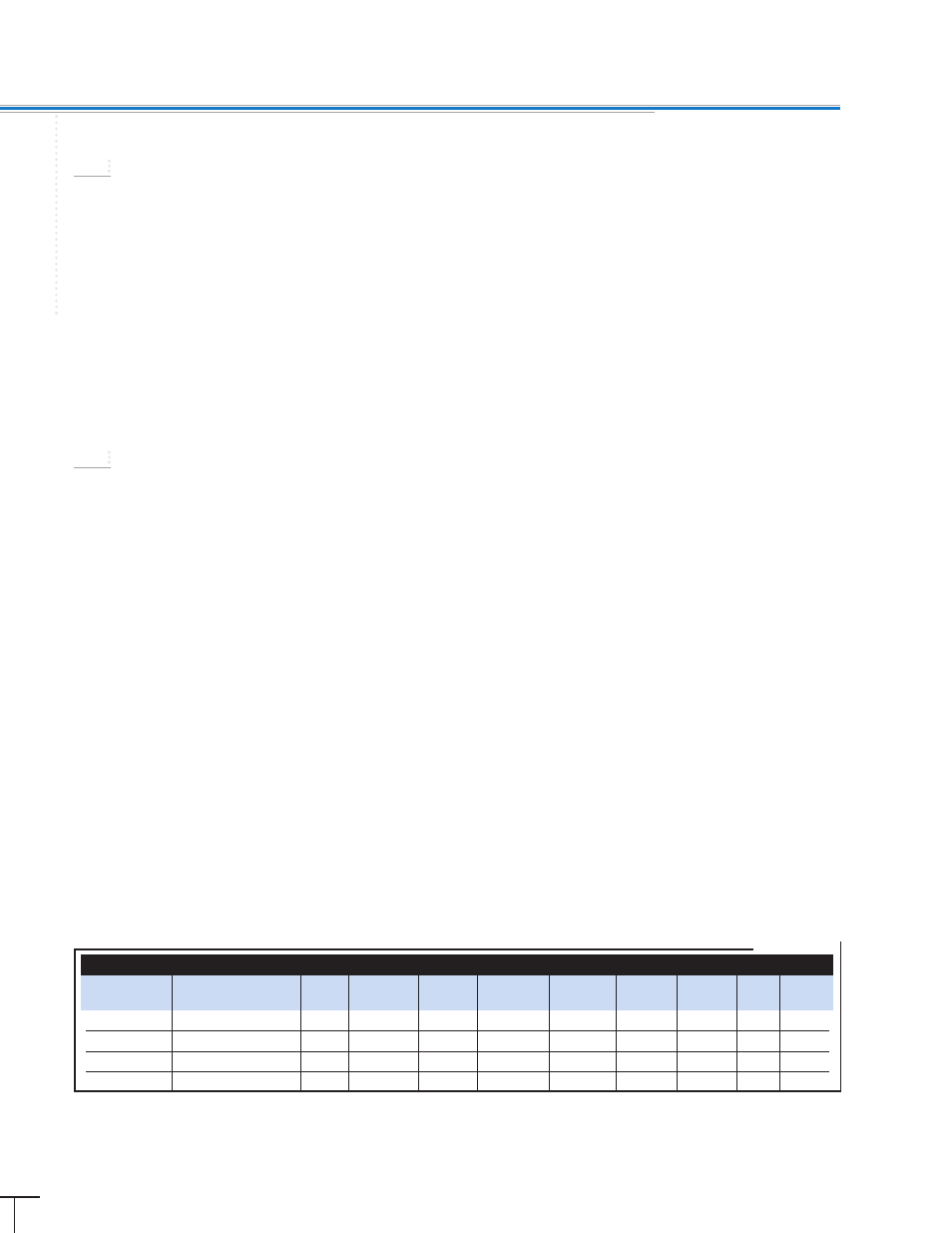

Standard Sizes of Coarse Aggregate (Weight % Finer Than Sieve Openings)

ASTM D448

Nominal Size

3"

2-1/2"

2"

1-1/2"

1"

3/4"

1/2"

3/8"

3/16"

Gradation

Square Openings

2

2-1/2" to 1-1/2"

100%

90-100%

35-70%

0-15%

0-5%

4

1-1/2" to 3/4"

100%

90-100%

20-55%

0-15%

0-5%

5

1" to 1/2"

100%

90-100%

20-55%

0-10%

0-5%

57

1" to No. 4

100%

95-100%

25-60%

0-10%

T A B L E

2

Components

B A L L A S T