Conditions, issues and ratings, Green roof design, The issue – Dow Protected Membrane Roof EN User Manual

Page 18: Discussion, Conclusion, Pmr assemblies are ideal for green roof designs

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

C

O

N

D

I

T

I

O

N

S

,

I

S

S

U

E

S

A

N

D

R

A

T

I

N

G

S

–

S

p

e

c

i

a

l

C

o

n

d

i

t

i

o

n

s

a

n

d

I

s

s

u

e

s

1 7

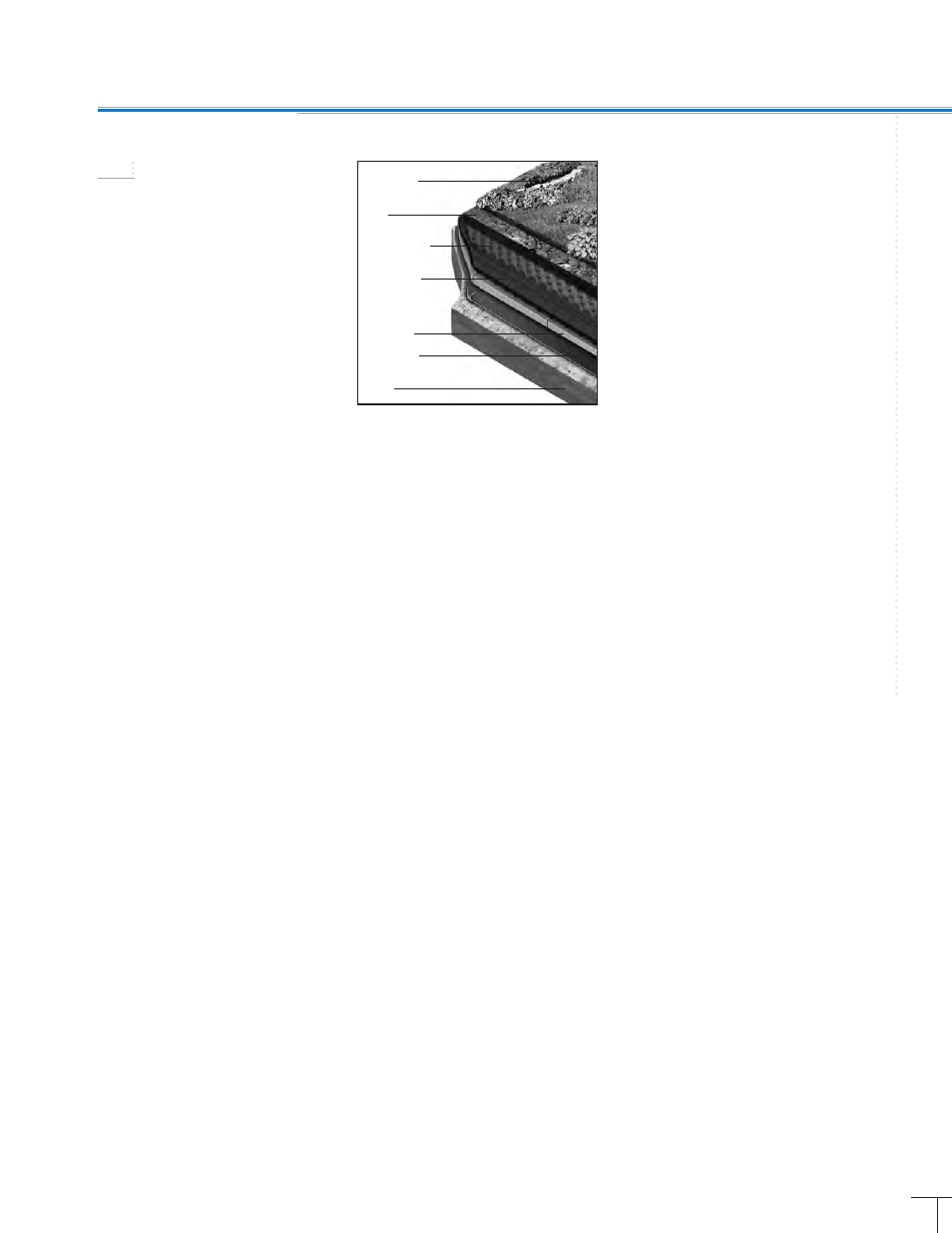

Green Roof Design

THE ISSUE

Can PMR assemblies be used

for “green roof” designs?

DISCUSSION

In a “green roof” design, the

ballast in a PMR assembly is

essentially replaced with green

material – usually soil and

plantings – plus a drainage layer

directly on top of the insulation

(Figure 6). Replacing conven-

tional ballast with vegetation can

limit storm water runoff and, by

filtering the runoff through the

plants, also improve the quality

of the runoff. The plantings not

only ballast the insulation, they

can, depending on the configu-

ration, also add additional

R-value to the roof assembly.

Green roofs provide habitat for

insects and other wildlife and

often are considered in buildings

applying for LEED

††

(Leadership

in Energy & Environmental

Design) certification.

Many materials may be suitable

as ballast, provided they are

compatible with the insulation,

prevent flotation, shield ultra-

violet light and provide a Class

A fire-resistant roof finish.

The roof structure must also be

designed to accommodate the

dead load from the additional

weight of the plantings (including

when they are fully saturated by

rainfall and covered in several

feet of snow), plus any live load

from traffic, if applicable. It is

also important to design the

roof slope and drainage system

to accommodate rain runoff.

Figure 6: Green Roof Design

PMR assemblies are ideal for

green roof designs:

• The membrane is protected

under the insulation.

• Because STYROFOAM

™

extrud-

ed polystyrene products come

in a range of compressive

strengths, the insulation layer

can be designed to withstand

the higher dead loads.

• STYROFOAM insulation is

proven to outperform in a

moist environment.

• STYROFOAM insulation has a

high modulus of elasticity,

allowing it to perform under

long-term live or cycle loading.

Maximum recommended

dynamic (live) load is 1/10 of

the rated compressive strength

for 1,000,000 repetitions to

address creep and fatigue

guidelines.

Typically, a drainage layer is

placed over the insulation to

direct runoff to the drains, as

well as keep the top surface of

the insulation “diffusion open.”

(See “Moisture Absorption” on

page 16 for details.) This

drainage layer usually includes a

fabric over the insulation to pro-

tect the joints and keep them

open for drainage. Any stone

used for this drainage layer must

be clean and have a low per-

centage of fines. In some cases,

a drainage mat combined with a

filter fabric has also been used

successfully to create the neces-

sary air space.

For additional information on

green roof design, see:

Design Guidelines for Green Roofs,

by Steven Peck and Monica

Kuhn, B.E.S., B. Arch., OAA, an

OAA and CMHC publication,

available at http://www.cmhc-

schl.gc.ca

CONCLUSION

PMR assemblies are ideally

suited to green roof designs.

Vegetation

Soil

System Filters

Filter Fabric

STYROFOAM™

Extruded

Polystyrene

Insulation

Membrane

Deck

††

Trademark of the U.S. Green Building Council

Conditions, Issues and Ratings

S P E C I A L

C O N D I T I O N S

A N D

I S S U E S