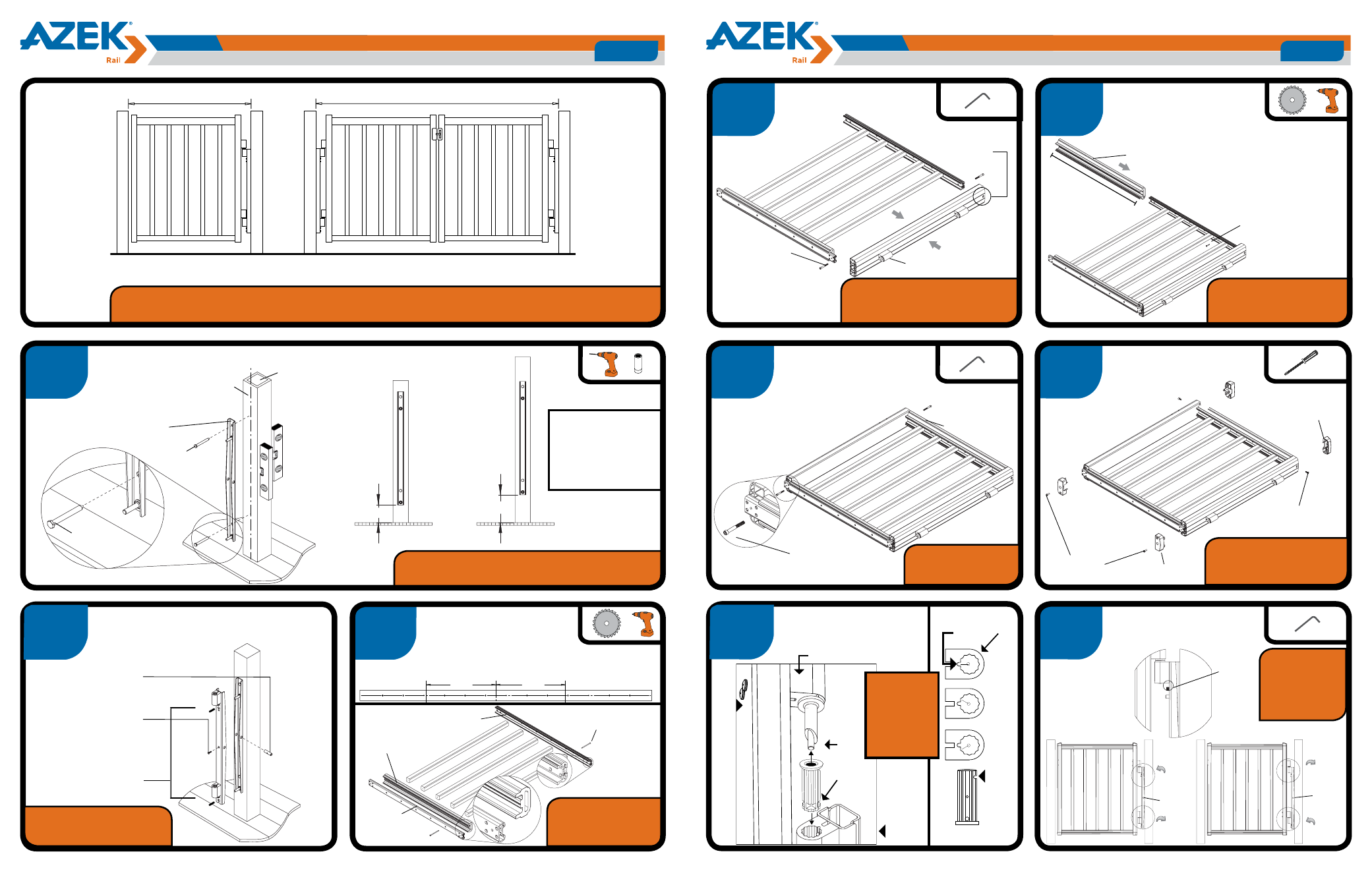

Page 2, Page 3, Slide on then fasten top rail – AZEK Gate User Manual

Page 2: Attach inner hinge plate to post, Assemble end caps, Adjust level of gate using setscrews, shown, Assemble hinge side end, Tools

4”

gap

42”gate

4”

gap

6 3/8”

3 3/8”

• Do not over

torque screws

into post.

1

6

2

8

3

4

5

Assemble Outer Hinge Plate

Drop Gate Assembly

onto Hinge Assembly

Assemble Latch Side

End and fully tighten

shoulder screws

Assemble Balusters

to Top Extrusion and

Bottom Rail/Bottom Extrusion

Slide on then

Fasten Top Rail

Assemble Hinge Side End

step 1

step 2

6 3/

8

2. Lock Hinge Pin

in Place with 3/4”

#10 Flat Head Screw

1. Insert Hinge Pin

step 4

step 5

step 6

step 7

1/4-20 Shoulder

Screws (x8)

Hinge Side

step 4

step 5

step 6

step 7

2. Slide on Hand Rail

3. Fasten with #8

Wood Screws (x4)

Tools

Level

Phillips Screw Driver

Wrench

Allen Keys

Drill

Attach Inner Hinge Plate to Post.

Tools

Level

Phillips Screw Driver

Wrench

Allen Keys

Drill

Hinges Pre-Assembled

3/8 Lag Screw

(x2)

Drill 5/16” Pilot Holes for

Lag Screws centered on post.

Sleeve

Post

Lag screw

goes above

threaded stud

3. Insert 3/8-16

set screw

1.

2.

Balusters need to

be trimmed 1/4” for

Trademark Rails.

Check hinge extrusions for alignment

with straightedge across both extrusions.

Loosen screws and adjust if necessary.

Check local code

requirements as to

required distance

between balusters to

avoid child entrapment.

Top Extrusion

Bottom

Extrusion

Cut Bottom

Rail to 34 1/2”

3” #8 Wood

Screws (x12)

Do not fully tighten shoul-

der screws until second side

end is attached in Step 6.

Be sure to cut top

rail accurately to

avoid excessive gap.

1. Cut Hand Rail

to 34 1/2”

7

Assemble End Caps*

Latch Side

1/4-20 Pan

Head Screws (x2)

Bottom

End Cap (x2)

1/4-20 Flat Head

Screws (x2)

Top End

Cap (x2)

Tools

Level

Phillips Screw Driver

Wrench

Allen Keys

Drill

Phillips

3.

3.

17 1/4

17 1/4

Tools

Level

Phillips Screw Driver

Wrench

Allen Keys

Drill

9

Adjust Level of Gate

Using Setscrews, shown.

step 10

step 9

Setscrew

step 10

step 9

TO ANGLE GATE UP:

Loosen

set screw

Tighten

set screw

Pivot

step 10

step 9

TO ANGLE GATE DOWN:

Loosen

set screw

Tighten

set screw

Pivot

Tools

Level

Phillips Screw Driver

Wrench

Allen Keys

Drill

Latch Side

1/4-20 Shoulder

Screws (x4)

1/4-20 Shoulder

Screws (x4)

To ensure baluster spacing, find center between holes & measure 17 1/4” to cut.

CUT

CUT

Tools

Level

Phillips Screw Driver

Wrench

Allen Keys

Drill

Be sure BOTH inner hinge plate and post are

properly secured, square, and plumb.

Hinge Plate Orientation

Screw hole goes

toward the top.

Closed

30°

Open

Positive

Close

Gate

Post

Tools

Level

Phillips Screw Driver

Wrench

Allen Keys

Drill

For a 2” gap:

(36” gate: 1 3/8” gap)

(42” gate: 4 3/8” gap)

Ref.

Mark

Cam

Cam

Ref.

Mark

36”gate

Ref.

Mark

Tighten all

Shoulder Screws

*Please refer to step

7a for additional dou-

ble gate instructions.

NOTE: Gate Kit will not work with Tall Boys (steel surface mount bracket)

Read all instruction prior to assembling gate components for either single or double gate

Reference

mark on cam

needs to line

up opposite

reference

mark on hinge

extrusion.

A 42-1/4” opening between post sleeves is

required for installation of a single gate.

A 83-1/4” opening between post sleeves is required for

installation of a double gate.

42-1/4”

83-1/4”

GATE INSTALLATION GUIDELINES for

AZEK Premier AZEK Trademark

Page 2

GATE INSTALLATION GUIDELINES for

AZEK Premier AZEK Trademark

Page 3

© 2012 All rights reserved. AZEK Building Products, Inc.

www.AZEK.com

© 2012 All rights reserved. AZEK Building Products, Inc.

www.AZEK.com

Hinge Extrusion

Hinge

Ext.

Measure to Bottom of Plate

This Cut

is Critical!

Check level

of Gate while

Gate is in

the Closed

Position.

Note: Check hinge extrusions for

alignment with straightedge across

both extrusions. Loosen

screws and

adjust if necessary.