Working with azek deck boards, Expansion and contraction – AZEK Deck EN User Manual

Page 4

Page 4

Expansion and Contraction

AZEK Deck/Rim Joist Covers/Riser will have expansion and contraction with changes in temperature,

unlike wood whose size will fluctuate with moisture changes. The expansion and contraction encountered

may result in slight gaps, which might be noticed at the ends of boards or in splice joints. Fastening the

deck boards according to the Installation Guidelines will help minimize expansion and contraction.

• Expansion/contraction is most significant where extreme temperature change may exist.

• Best practice is to cut and fasten the deck boards as soon after cutting as possible.

• Install the boards together tightly at splices or miters.

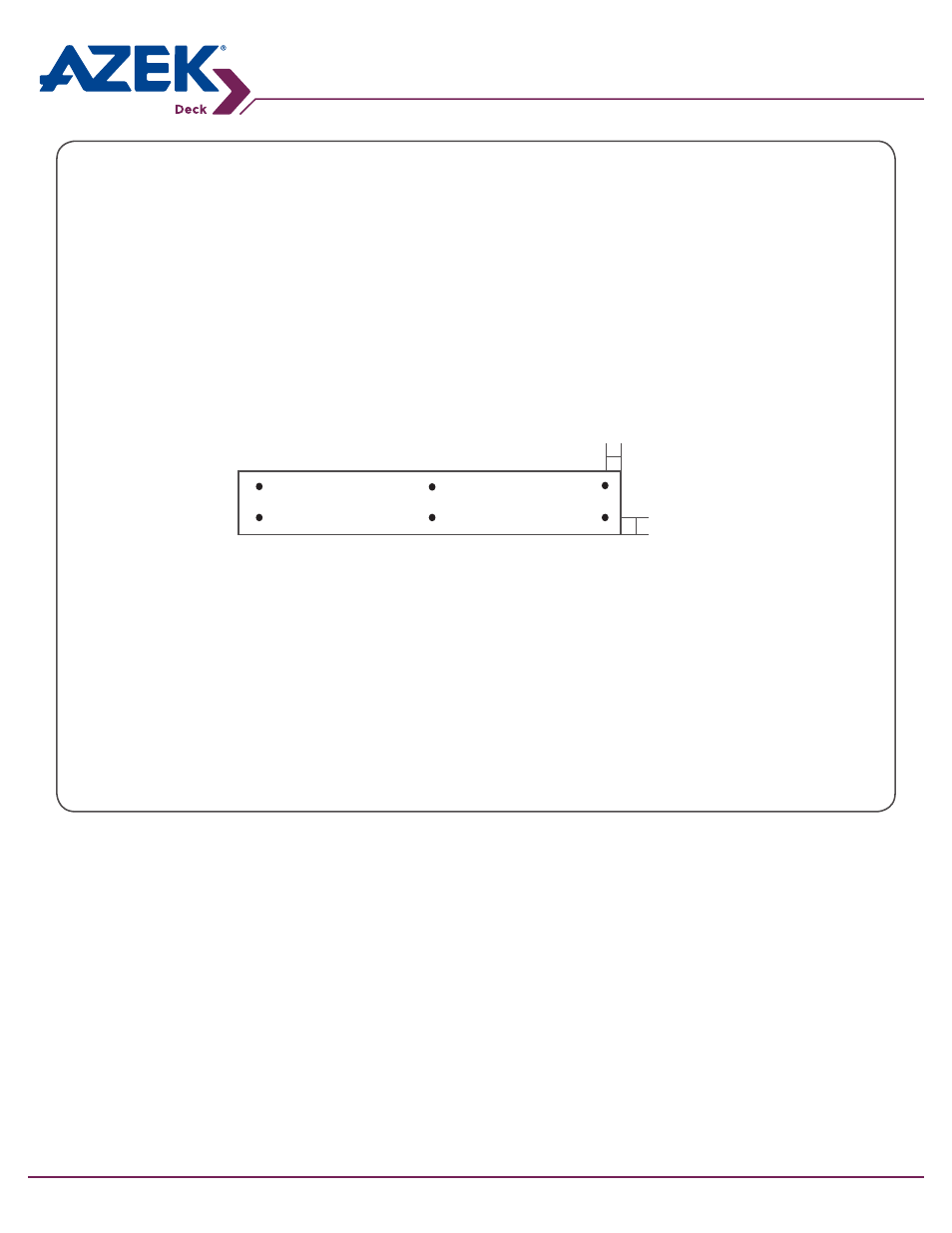

• Be sure to fasten ends of boards, splices, or abutments to building or structure securely into framing

using 2 screws. Position the screws at or within 1/2” of each board end or joint and 3/4” from side of

deck plank.

• Provide a 1/8” to 1/4” side to side gap between deck boards.

• In areas with obstructed airflow such as roofs and on-grade applications, a minimum of 1-1/2” sleeper

system supported by and connected to the substructure over which the deck is built is required.

• All deck frames and substructure should be securely attached to ground footings or building

structure. No floating substructures should be used (from preparation section AZEK).

• For best results, stagger splices and miters across deck surface so that all splices and miters do not

break on the same joist or beam.

• To further minimize expansion and contraction, proper ventilation and air flow should be considered.

• Some area building codes may require double joisting when joining boards end to end. Double

joists are always required at butt joints when using CONCEALoc. Always check with your local code

authority for specific requirements before installation.

3/4”

1/2”

Working with AZEK Deck Boards