Equipment startup, 1 fastener inspection, 2 output adjustment – Pulsafeeder Pulsa GLM DM7 User Manual

Page 9

9

6. Equipment Startup

6.1

Fastener Inspection

All pump fasteners should be checked prior to pump operation, and occasionally

during use. This would include reagent head mounting bolts, motor mounting bolts,

and the hardware that secures the pump to its foundation. Most hardware can be

checked simply to ensure it is not loose. However, utilize the following values when

checking reagent head bolt torque:

Model

Material

Reagent Head Bolt Torque

# Bolts and size

N-m

In. - Lbs

DM7

Plastic

(8) M10 * 1.5

8.5

75

Metal

(8) M10 * 1.5

8.5

75

6.2

Output Adjustment

All GLM

®

DM7 pumps have a hand wheel for manual stroke adjustment. The hand

wheel can be adjusted to any point from 0 to 100%. This value represents the stroke

length setting and therefore the flow rate of the pump relative to its maximum output.

1. Turn the red lock screw counterclockwise to release the stroke lock. Making

adjustments without releasing the lock may damage the mechanism.

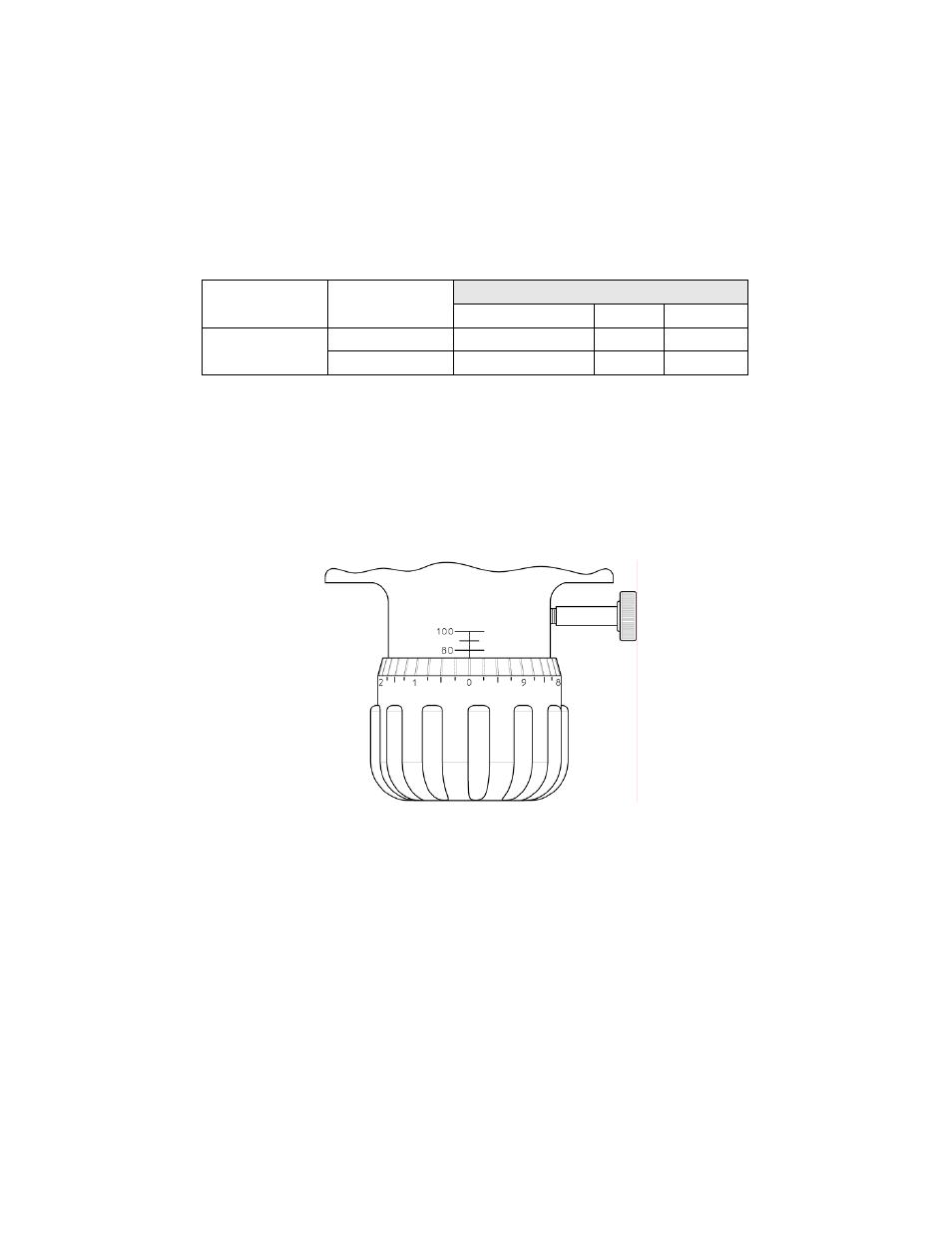

Figure 4, stroke adjustment knob and scale

2. Adjust the hand wheel to the desired output.

a. The stroke barrel indicates stroke length in 20% increments.

b. The hand wheel indicates stroke length in 0.25% increments.

For example, to set the pump to 75% stroke length, (starting from the factory default

setting of 0%) turn the hand wheel clockwise until the 60% indicator on the stroke

barrel is aligned with the edge of the knob at the “0” position on the knob scale.

Continue the clockwise rotation until the hand wheel indicator passes zero again (this

is 70%) and comes to 5, this is 75%. Refer to Figure 4.

3. Turn the lock screw clockwise to lock the stroke adjustment into position.

Adjustments can be made while the pump is at rest or operating, although

adjustments are easier to make while the pump is in operation.