3 check valves – Pulsafeeder Pulsa GLM DM7 User Manual

Page 19

19

7.3

Check Valves

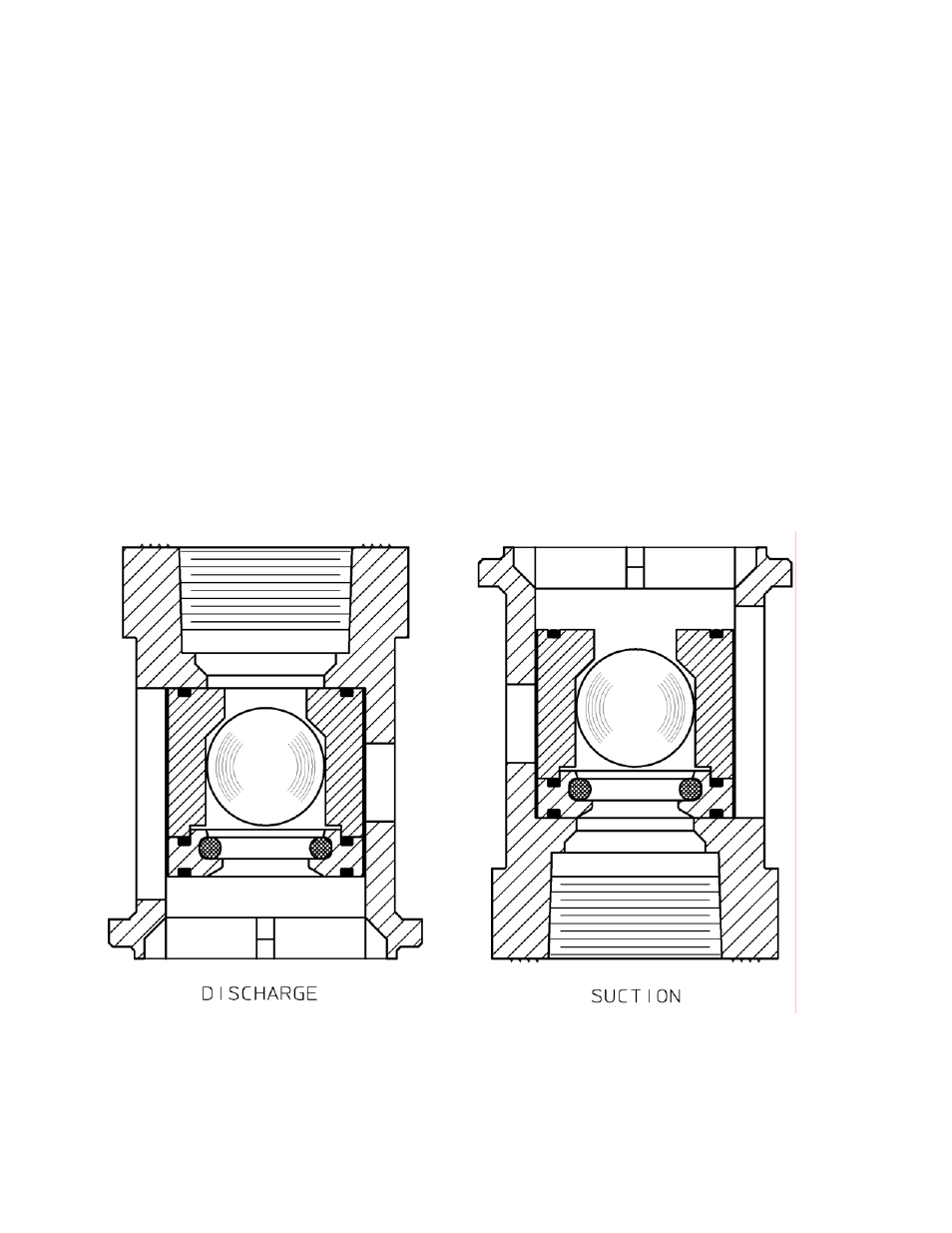

Most fluid metering problems are related to check valves. Problems usually stem from solids

accumulation between valve and seat, corrosion of seating surfaces, erosion, or physical

damage due to wear or the presence of foreign objects.

The valve incorporates a ball, guide, and seat. Flow in the unchecked direction lifts the ball

off the seat, allowing liquid to pass through the guide. Reverse flow forces the ball down,

sealing it against the sharp edge of the seat. The guide permits the ball to rotate but

restricts vertical and lateral movement in order to minimize “slip” or reverse flow. Ball

rotation prolongs life by distributing wear over the entire surface of the ball. Since ball return

is by gravity, the valve must be in the vertical position in order to function properly. Parts are

sealed by “O”-rings.

GLM

®

DM7 xpumps utilize a multi-part check valve assembly, secured to the reagent head

with a union nut clamping arrangement (plastic construction) or a tie-bar arrangement (metal

construction).

Figure 12, check valves DM7