Nor-Lake Angled Ice Cream Merchandisers User Manual

Page 9

9

ELECTRICAL CONNECTIONS

The controller is provided with screw terminal block to connect cables with a cross section up to 14 AWG. (2,5 mm

2

).

Before connecting cables make sure the power supply complies with the control’s requirements. Separate the probe

cables from the power supply cables, from the outputs and the power connections. Do not exceed the maximum

current allowed on each relay, in case of heavier loads use a suitable external relay.

PROBE CONNECTIONS

The probes shall be mounted with the bulb upwards to prevent damages due to casual liquid infiltration. It is

recommended to place the thermostat probe away from air streams to correctly measure the average room

temperature. Place the defrost termination probe among the evaporator fins in the coldest place, where most ice is

formed, far from heaters or from the warmest place during defrost, to prevent premature defrost termination.

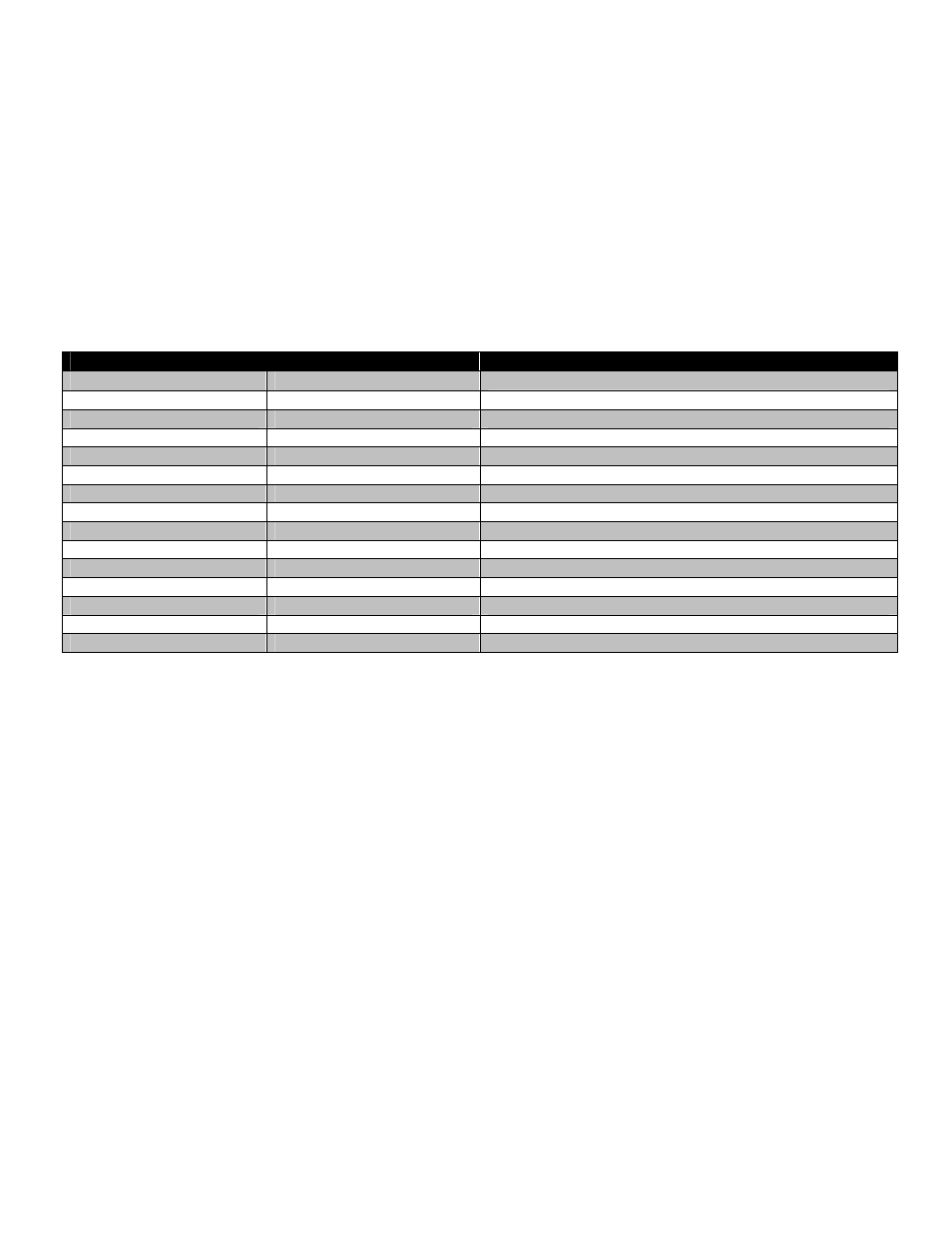

SENSOR PROBE TEMPERATURE AND RESISTANCE

Temperature

Resistance

°F

°C

Ohms

-29.2 -34

683,100

-20.2

-29

499,200

-9.4 -23

347,100

-0.4

-18

259,500

10.4 -12

185,200

19.4

-7

141,200

30.2 -1

103,100

32.0

0

97,950

39.2 4

80,040

50.0

10

59,700

60.8 16

45,000

69.8

21

35,820

80.6 27

27,500

89.6

32

22,210

FAN OPERATION AND VIBRATION; VOLTAGE CHECK

Check the operation of the fan blade and also check for vibration noises due to refrigerant lines rattling against one

another. While the cabinet is in operation, check the voltage draw and the amperage draw versus this rating on the

nameplate. Voltage should be checked at the compressor terminals while the compressor is initially starting. The

cabinets are designed to operate at +/- 10% of 115/60/1. This means at time of start-up, the voltage should be

between 103 volts and 126.5 volts at the compressor.

FINAL CHECK LIST

A.

Check operating pressures.

B.

Check electrical requirements of unit to supply voltage.

C.

Set temperature control for desired temperature range.

D.

Check system for proper defrost settings and operation.

E.

Check condensing unit for vibrating or rubbing tubing. Dampen and clamp as required.