Nor-Lake Angled Ice Cream Merchandisers User Manual

Page 6

6

SERVICE INSTRUCTIONS

ELECTRICAL

WARNING

Before servicing electrical components in the case or the doors or door frames make sure all power to case is

off. Always use a qualified technician.

It is recommended that a separate circuit be run for each cabinet to prevent another appliance blowing the fuse or

HAC&R C/B, causing loss of product. This circuit should be sized according to the amp rating on the cabinet data

label.

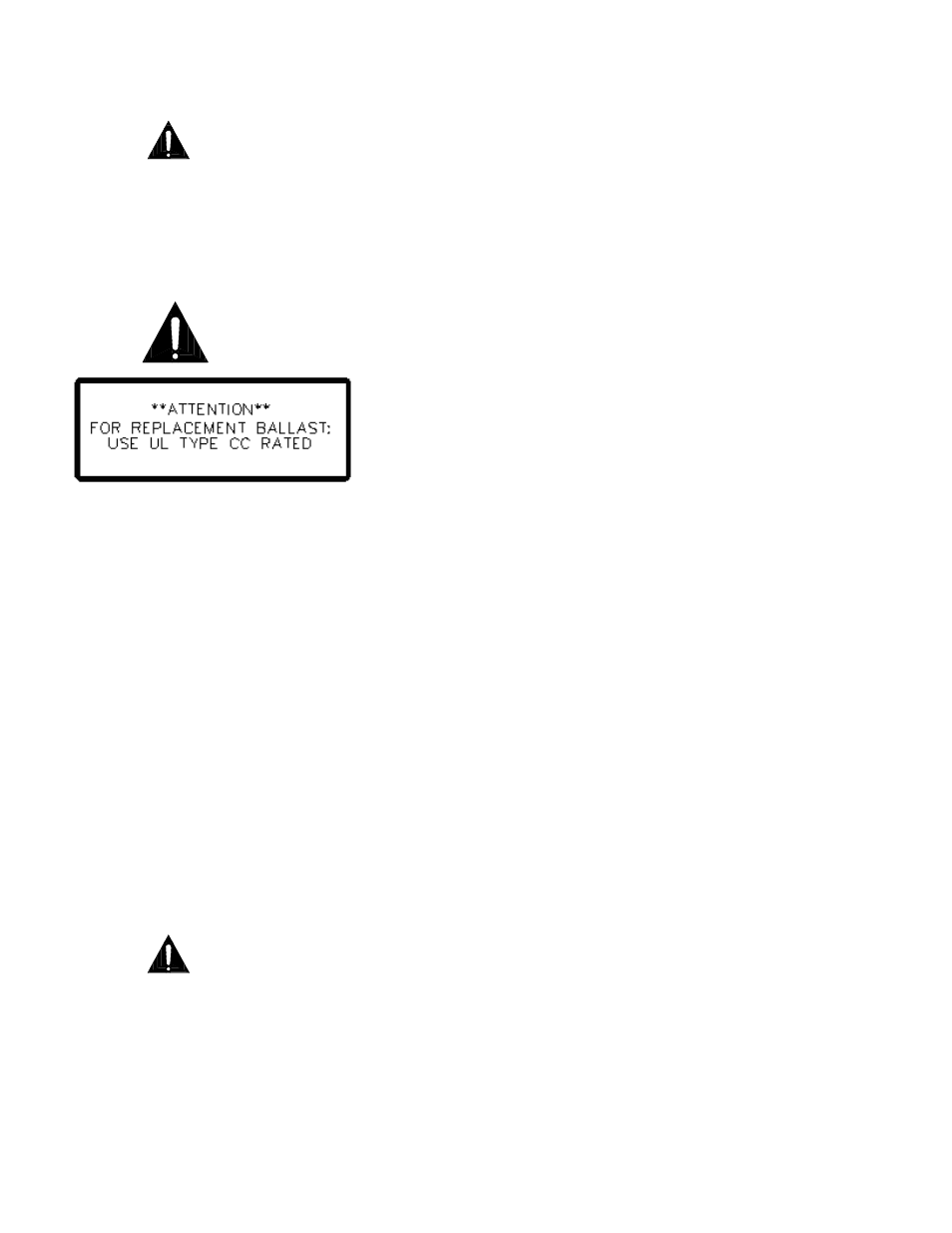

NOTICE

For mode

ls with electronic ballast only:

For replacement ballast, use only ballast that complies with UL Type CC rating if unit is equipped with

electronic ballast.

SPECIAL SERVICE SITUATION:

A. There are rare occasions when the refrigerant charge must be evacuated from a cabinet in order to perform

service work. In those situation, Manufature recommends that a refrigerant reclaimer be used according to the

EPA guidelines to eliminate the possibility of refrigerant being released to the atmosphere.

B. If moisture or liquid is observed around or under the cabinet, an immediate investigation should be made by

qualified personnel to determine the source of the moisture or liquid. The investigation made should determine

if the cabinet is malfunctioning or if there is a simple housekeeping problem. Moisture or liquid around or

under a cabinet is a potential slip/fall hazard for persons walking by or working in the general area of the

cabinet. Any cabinet malfunction or housekeeping problem that creates a slip/fall hazard around or under a

cabinet should be corrected immediately.

OPERATING CONDITIONS AND PRESSURES

With room ambient temperature of +80 F and cold cabinet (unit cycling on control):

Suction Pressure

2 to 5 psig

Head Pressure

240 to 260 psig

TEMPERATURE SENSOR, DEFROST HEATER, AND FAN MOTOR REPLACEMENT

WARNING Before making any change, the technician should disconnect power to the cabinet.

To change a temperature sensor (cabinet zone sensor or defrost termination sensor), simply disconnect the sensor

wires from the controller and replace the new sensor in the original position. Use plastic tie to tighten the zone sensor.

Insert the sensor for defrost termination firmly into the evaporator coil, in between the fins. Make sure the sensor wires

do not touch or are not close to any heater rods.

To change defrost heater – remove screws from drain pan and pull down – remove screws from coil mounting straps –

spring straps open – remove heater shield – pull heater out of slots in coil fins.

To change fan motor – disconnect fan motor leads – remove screws from fan guards and motor mounts.