Nor-Lake Angled Ice Cream Merchandisers User Manual

Page 8

8

HOW TO CHANGE a parameter value

1. Enter the Programming mode by pressing the SET and DOWN

▼

keys for 3 seconds (LEDs

under DEF and COMP start blinking).

2. Select the required parameter by pushing

the UP ▲ or DOWN▼ arrows

3. Press the “SET” key to display its value (now only the COMP LED is blinking)

4. Use

“UP” or “DOWN” to change its value

5. To exit: Press SET + UP ▲ or wait 15s without pressing a key.

NOTE 1: The set value is stored even when the procedure is exited by waiting the time-out to expire.

NOTE 2: Manufacture’s SETPOINT is set at a recommended –10

°F at the factory for low temperature(LT).

NOTE 3: To scroll down the parameters without changing them, press the DOWN button.

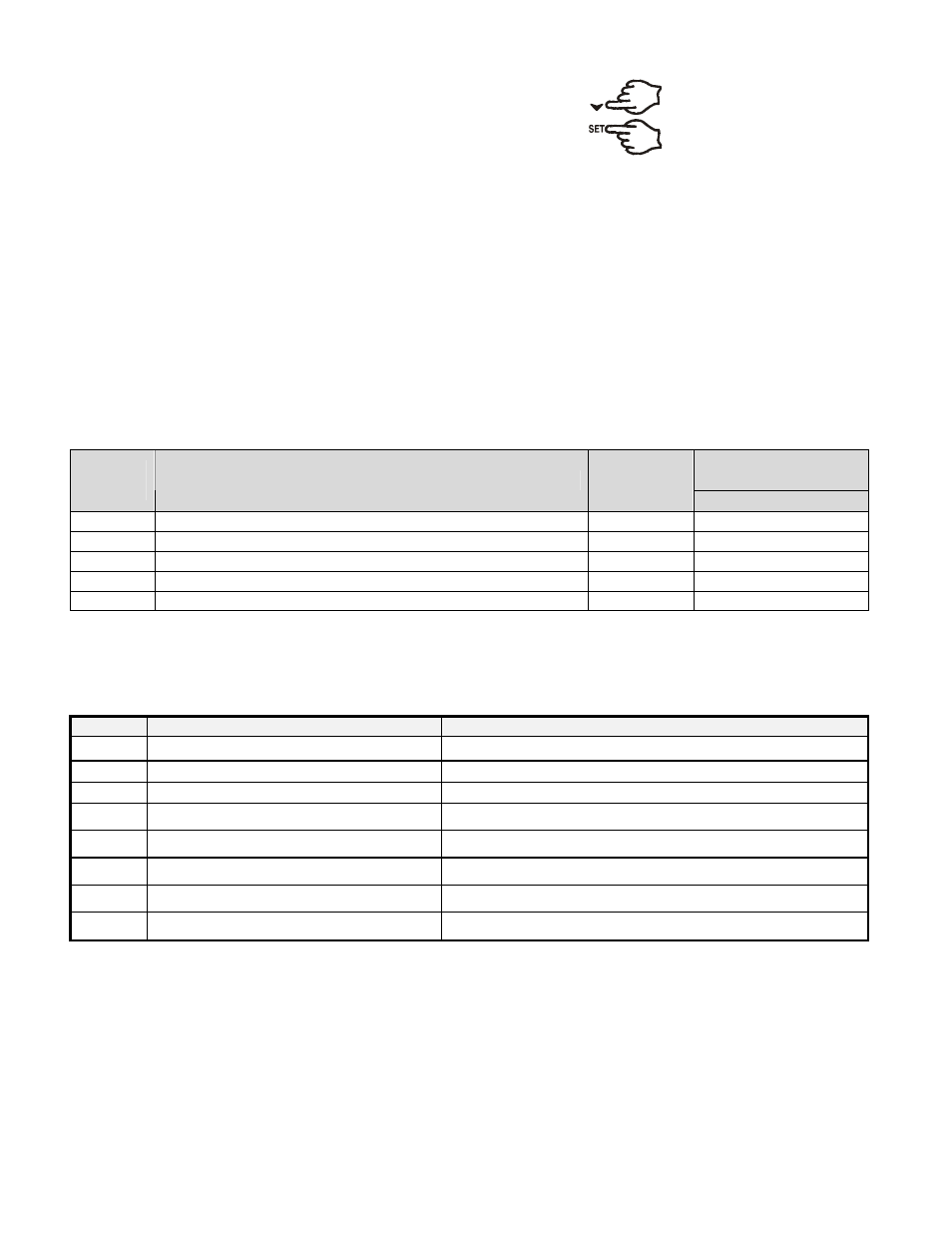

LIST OF PARAMETERS

Here is a list of the parameters the value of which can be changed in the programming mode, as well as

their ranges.

Factory

Setting

Display

Symbol

Description

Range

MF122

St

Temperature set point

-16 to 5°F

-10

° F

Hy

Cut-out temperature is Set + Hy, Differential

1 to 255°F

10

° F

AU

High temperature alarm is enabled after a delay

230°F

15

° F

AL

Low temperaturealarm is enabled after a delay -58°F

-25

° F

Ad

Alarm delay

0 to 255 min

30

ALARM SIGNALS

Message

Cause

Outputs

“P1”

Room probe failure

Compressor output according to par. “Con” and “COF”

“P2”

Evaporator probe failure

Defrost end is timed

“HA”

Maximum temperature alarm

Outputs unchanged.

“LA”

Minimum temperature alarm

Outputs unchanged.

“dA”

Door open

Compressor and fans restarts

“EA”

External Alarm

Output unchanged

“CA”

Serious External alarm(i1F=bAL)

All output off

“CA”

Pressure switch alarm (i1F=PAL)

Outputs unchanged.

NOTE:

Probe alarms “P1” and “P2” start some seconds after the fault in the related probe; they

automatically stop some seconds after the probe restarts normal operation. Check connections

before replacing the probe.

Temperature alarms “HA” and “LA” automatically stop as soon as the thermostat temperature returns to

normal values and when defrost starts.