202 screw press specifications – Anco Eaglin Screw Press 202 EN User Manual

Page 4

ANCO-EAGLIN, Inc.

120 North Chimney Rock Road • Greensboro, North Carolina 27409

336-855-7800

• FAX 336-855-7831 • E-mail: [email protected] • WWW.ANCOEAGLIN.COM

DISCLAIMER:

The seller makes no warranties, express or implied, including but not limited to the implied warranties of merchantability and fi tness for a particular purpose except

expressly stated in seller’s sales contract or sales acknowledgment form.

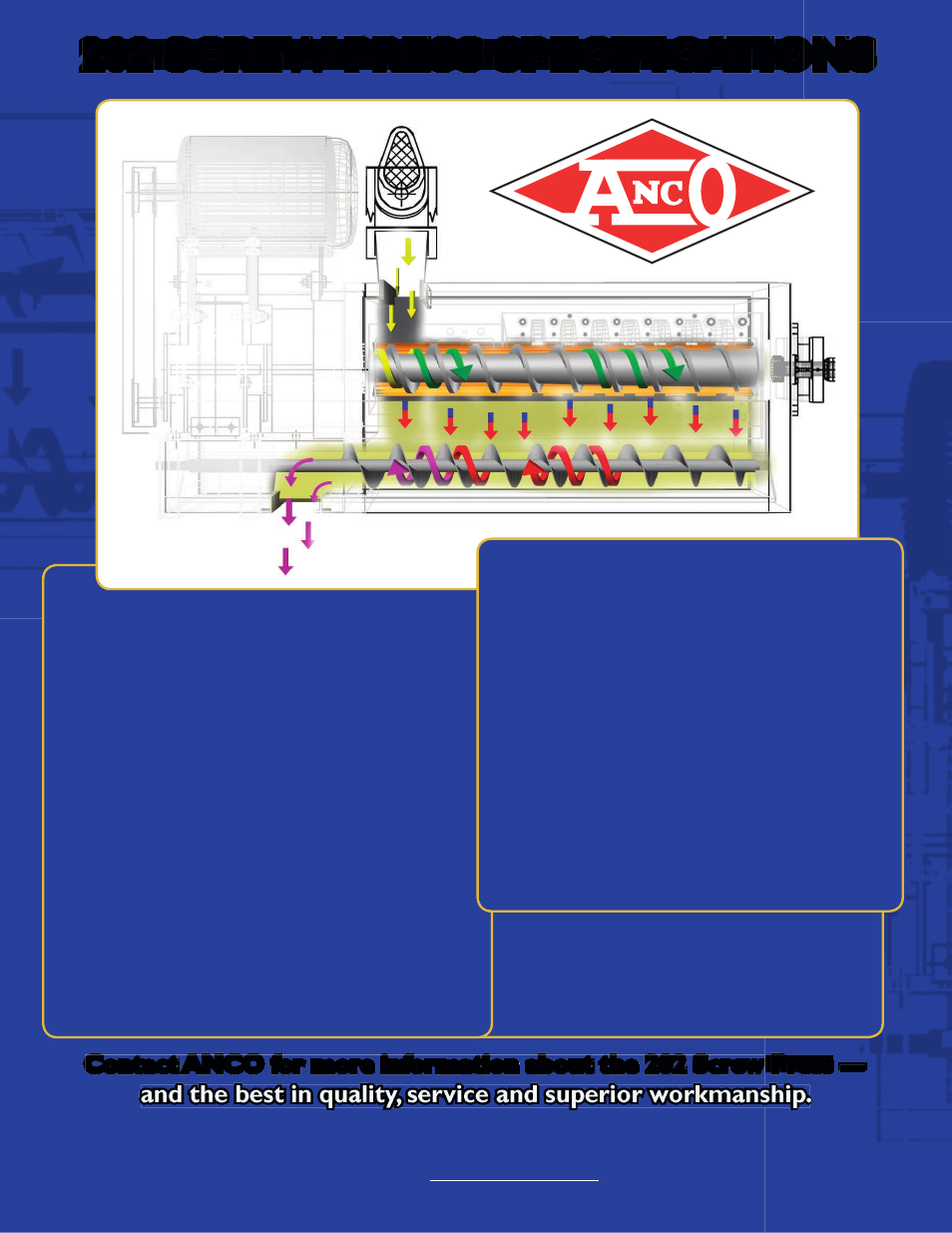

GENERAL SPECIFICATIONS

• Electrical: HP 40 (202-3) to 200 HP (202-8) see chart for

additional specifi cations.

Note: 202-8 can be provide with or without a side feed and is

equipped with a Patented # UK0306283.3 shaft design.

OPTIONS

• Cast or fabricated fl ighting.

• Side feed with VFD controls.

BENEFITS:

• Dual-automatic hydraulic press choke with center-press shaft

support bearing.

• Choke Guard — prevents press choke/shaft engagement.

• Compact design — allows replacement of lower production units

within the same fl oor space.

• State-of-the-art PLC controls in a NEMA 4 stainless-steel case.

• Sturdy, single-piece steel frame, line-bored and CNC-machined for

Precision tolerances.

Est. 1902

MORE THAN A CENTURY OF

ENGINEERING INNOVATON GOES INTO

EVERY ANCO 202 SCREW PRESS.

Since 1902, the Allbright-Nell Company (ANCO) has been an

innovator of one of the most dependable lines of specialized rendering,

food, chemical and related equipment. The company pioneered many

processes and machines that became standards of the rendering

industry, including:

• A batch cooker that assured fast, even cooking while extending the

life of the equipment and allowed the operator to preset precise

moisture levels.

• Automated blow tank systems for charging cookers.

• Controlled-cooker feed with a hydraulically operated raw product pump.

• Air -cooled condensers that operate as giant radiators to condense

cooking vapors.

• Heat recovery systems that produce useful, potable hot water for

other operations.

• The ANCO Continuous Hydrolyzer, which rapidly converts hair and

feather chemical composition to provide extremely high digestibility.

• An energy-reducing heat recovery system that preheats product.

• The introduction of a newly designed crax-press for the beef industry.

In 1993 a redefi ned company was created, ANCO-

EAGLIN, Inc. Today’s ANCO is focused in specialty

heating, evaporation and cooling equipment for

a multitude of products including the new ANCO

202 Screw Press.

202 SCREW PRESS SPECIFICATIONS

202 SCREW PRESS SPECIFICATIONS

202 SCREW PRESS SPECIFICATIONS

202 SCREW PRESS SPECIFICATIONS

202 SCREW PRESS SPECIFICATIONS

Contact ANCO for more information about the 202 Screw Press

Contact ANCO for more information about the 202 Screw Press

Contact ANCO for more information about the 202 Screw Press

Contact ANCO for more information about the 202 Screw Press

Contact ANCO for more information about the 202 Screw Press

Contact ANCO for more information about the 202 Screw Press

Contact ANCO for more information about the 202 Screw Press —

and the best in quality, service and superior workmanship.