Easy maintenance, Reduce labor, Flexible production capabilities – Anco Eaglin Screw Press 202 EN User Manual

Page 3

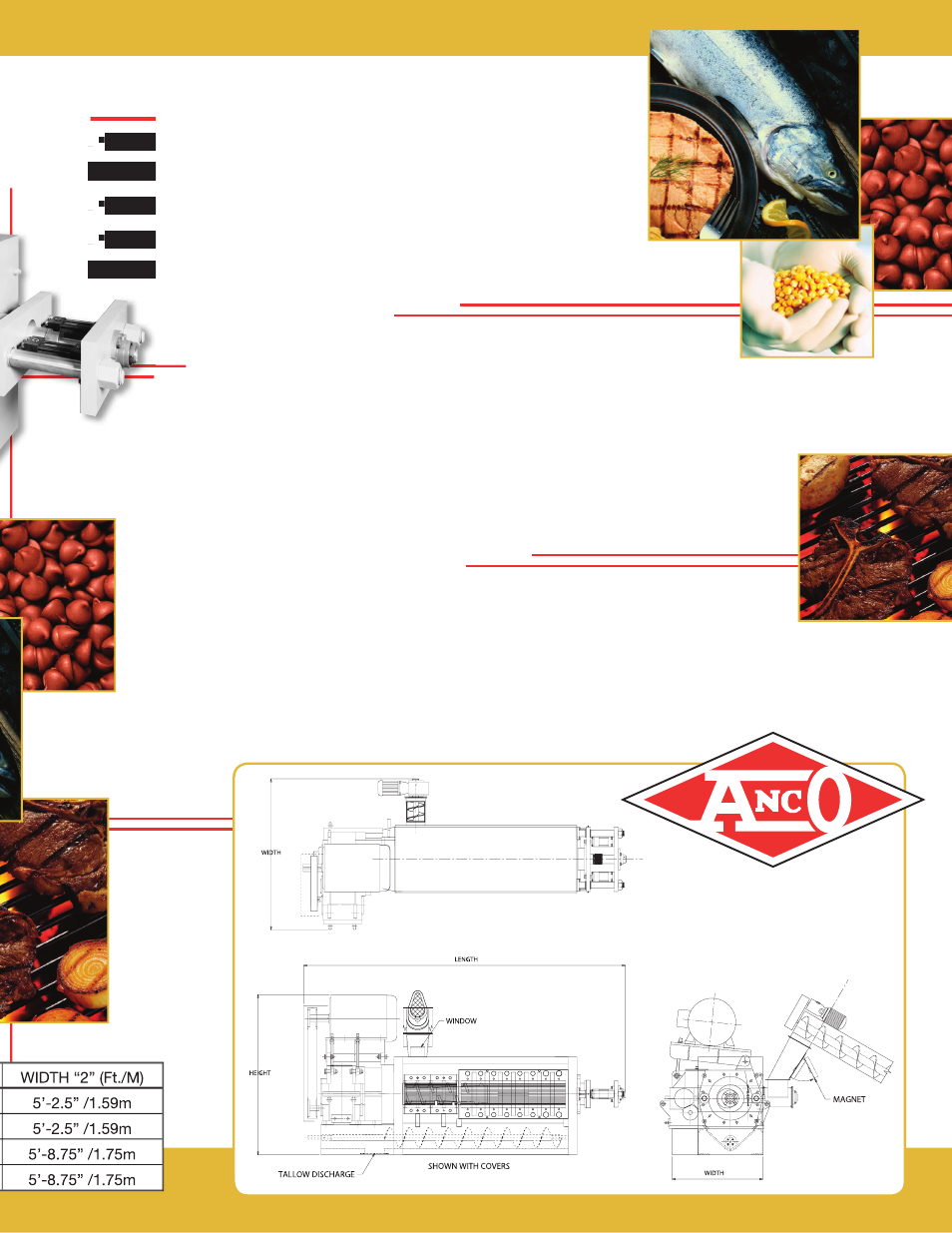

Easy Maintenance

• Integral POW-R-PAK II gear box — features an oil-fl ushed thrust bearing and

cooler, with a high 1.8 service factor design.

• V-belt design — softens start-up loads, which are directly related to certain types of gear failure.

• Simple, one-piece cage assembly with special wear-resistant parts — used throughout to provide

greater overall press reliability.

Reduce Labor

• Continuous, automatic PLC operation — frees labor personnel for other plant requirements.

• Special safety interlocks — monitors critical process functions, allowing the operator to

perform multiple duties simultaneously.

• Automatic solids/oil discharge conveyor — does not require the constant

attention of press-solids removal.

Flexible Production Capabilities

Capacity ranges of the ANCO 202 series — 1 TPH (202-3) to

4 TPH (202-8) pressed cake with low fat residuals of 8 – 10%.

V-belt drive — can be adjusted to varying product conditions.

Computer-modeled screw feeder — allows customers to produce a

cooler finished meal while handling softer infeed material.

Est. 1902