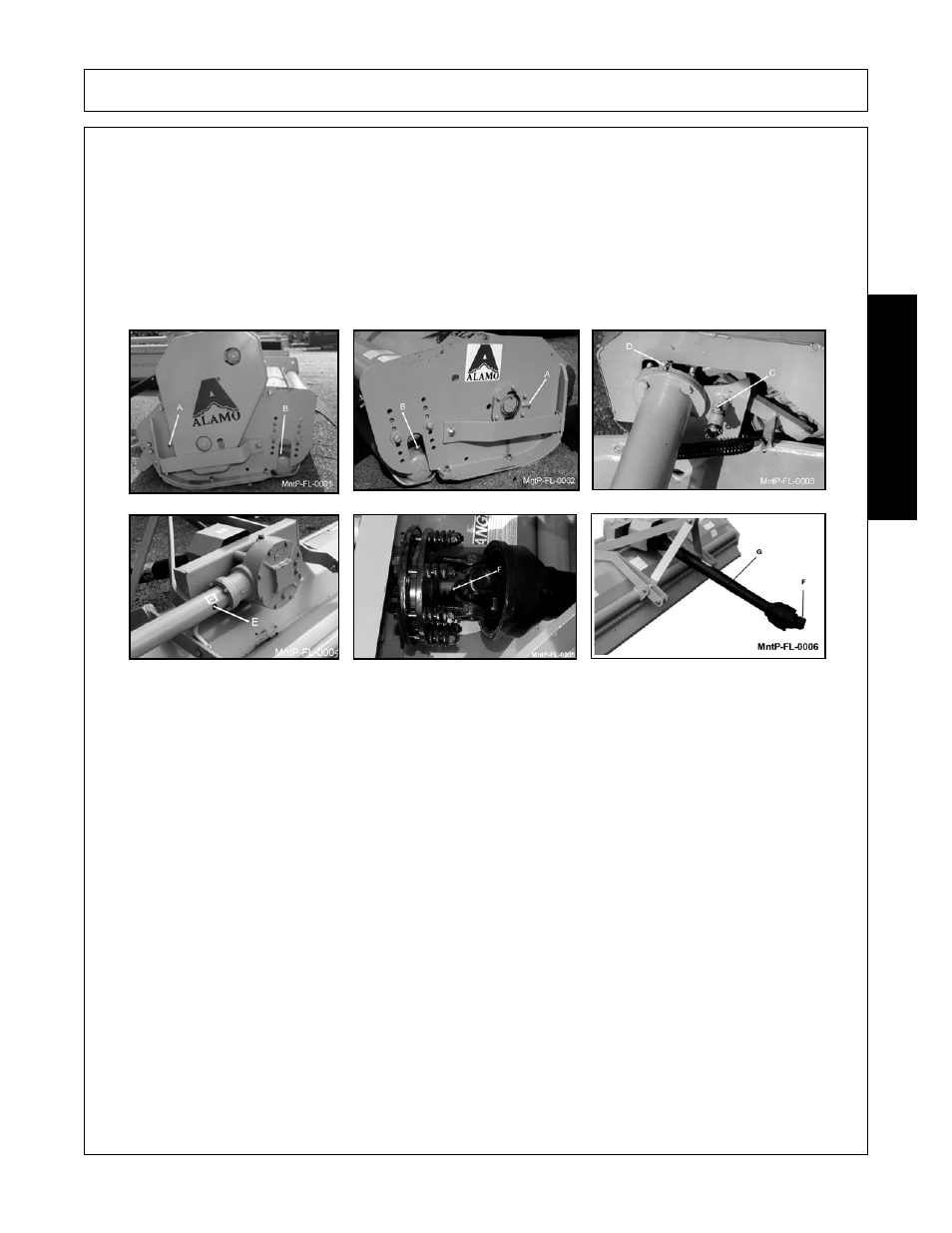

A. cuttershaft bearings, B. roller bearing, C. rear mower idler arm – Alamo SHD88 User Manual

Page 129: D. banjo bearing, E. banjo coupling, F. driveline yoke, G. driveline telescoping joint, Slip clutch, Slip clutch -3, Maintenance

MAINTENANCE

SHD 03/09

Maintenance Section 5-3

© 2009 Alamo Group Inc.

MAINTENANCE

A.

Cuttershaft Bearings

B.

Roller Bearing

C.

Rear Mower Idler Arm

D.

Banjo Bearing

E.

Banjo Coupling

F.

Driveline Yoke

G.

Driveline Telescoping Joint

Slip Clutch

.A slip clutch is incorporated in the PTO driveline. It is designed to slip, absorb the shock load, and protect the

driveline.

After the first hour of operation, the slip clutch should be checked for overheating. After this first check, the slip

clutch should be checked weekly or anytime there is overheating. To adjust the slip clutch, tighten the spring

bolts 1/8 (maximum) turn at a time. Bolts should NEVER be adjusted to the point where the springs are

compressed solid. Minimum spring compression length is 1-1/4”.

The slip clutch should be checked periodically and adjusted to compensate for wear. The lining plates are 1/8”

thick when new. Replace after 1/32” wear. If the mower has been idle for an extended period of time, or in wet

weather, before operating check to be sure the friction lining plates are not frozen or rusted together. Should

this freezing occur refer to the procedure described in the “Seasonal Clutch Maintenance” section on the next

page.