Troubleshooting – Karcher Système de recyclage des eaux usées WRP 16000 User Manual

Page 20

-

8

ƽ

Danger

Risk of accident while working on the unit.

During all tasks

First switch-on in voltage-less state,

switch off the emergency stop switch

and secure it against being switched on

again.

Shut off water supply.

–

Operator

Work designated with the sign “Opera-

tor” may only be carried out by persons

who have been instructed in the safe

operation and maintenance on the

wash plant

–

Customer Service

Work designated with the sign “Cus-

tomer Service” may only be done by the

fitters of Kärcher Customer Service or

fitters who have been authorised by

Kärcher.

There are indicator lamps in the switching

cabinet that display

–

Adding fresh water and

–

faults

.

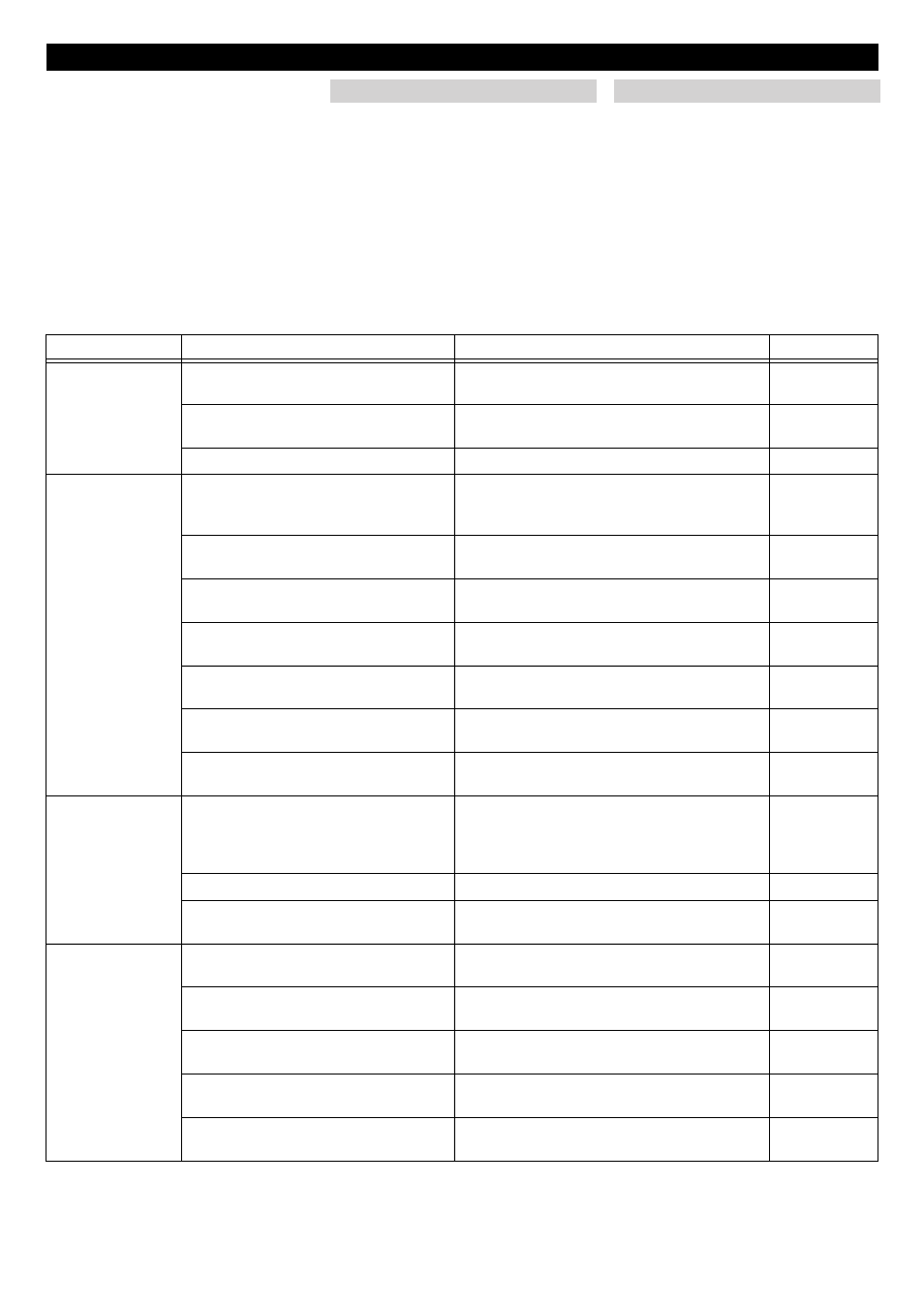

Troubleshooting

Who may remedy faults?

Fault indication

Fault

Possible cause

Remedy

By whom

Indicator Lamp

"Fault" illuminates

Motor protection switch of the immersion

pump has been triggered.

Reset motor protection switch; call Customer Ser-

vice if the problem recurs.

Operator

Float switch S15 in pump basin is defective Repair or replace float switch.

Customer Ser-

vice

Recycled water tank is empty.

see below

Message "Recycled

water tank empty"

displayed on wash-

ing system.

Water level in the pump basin is too low

and emergency fresh water supply has

failed

Refill pump basin; check emergency fresh water

supply; repair, if required.

Operator, Cus-

tomer Service

Immersion pump has failed, is dirty or de-

fective

Restart the plant by switching off and on; other-

wise call Customer service

Operator

Gravel filter plugged (filter output is too

low)

Backwash several times; if not successful,

change the gravel

Operator/Cus-

tomer Service

Pipe connections are leaky

Check all pipe connections; seal them, if required Operator, Cus-

tomer Service

Float switch S11 is defective or loose

Replace the float switch or reattach it

Customer Ser-

vice

Controls are defective

Check, repair or replace controls

Customer Ser-

vice

Multi-channel defective

Repair multi-channel valve; replace defective

parts

Customer Ser-

vice

Plant out of order

Programme selection switch in wrong posi-

tion.

Turn the programme selector switch to the posi-

tion "Operation without conductivity monitoring or

"Operation with conductivity monitoring" and

press the SET key.

Operator

Power supply is interrupted

Check power supply and ensure proper supply.

Operator

Controls are defective

Check, repair or replace controls

Customer Ser-

vice

Recycled water is

coloured or is foam-

ing too much

Sludge collector or pump basin is dirty

Emptying and cleaning the basins

Operator/ Dis-

posal agency

Improper detergents are used in the wash-

ing unit or washing hall

Use compatible detergents; rinse the system, if

necessary

Operator, Cus-

tomer Service

Detergent dosing in the washing unit is too

high

Check detergent dosing; reset, if necessary

Operator, Cus-

tomer Service

Washing place cleaned with incompatible

detergents

Replace water and rinse the basins

Operator

Backwash throttle in wrong position

Check the gravel fill and refill if necessary.

Adjust the backwash throttle

Customer Ser-

vice

20

EN